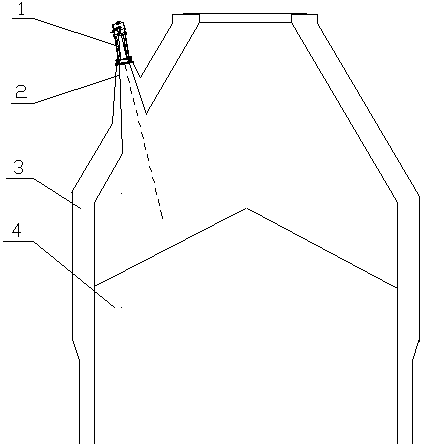

Microwave detection device of material level in dry quenching furnace

A technology for material level detection and dry quenching of coke ovens, which is used in measuring devices, furnace safety devices, coke ovens, etc. to eliminate influences, ensure normal operation, and extend heat transfer paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

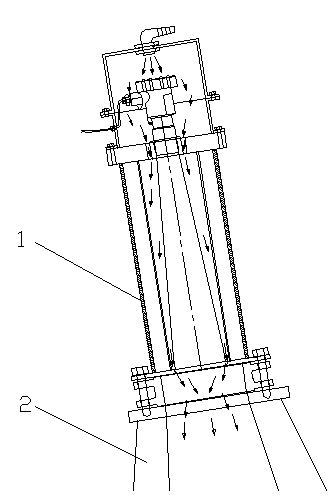

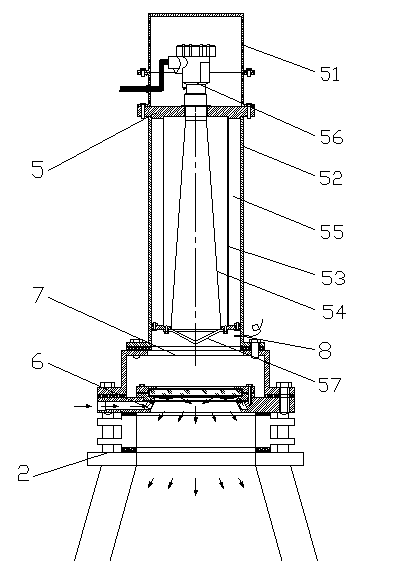

[0024] Such as image 3 , 4 As shown, a CDQ coke oven microwave level detection device includes a microwave detection part 5 and a temperature isolation part 6, and the microwave detection part 5 and the temperature isolation part 6 are isolated by a sealed air chamber 7, and the sealed gas The chamber 7 is equipped with a temperature monitoring device 8; the bottom of the microwave detection part 5 is sealed with a conical sealing cover 57, the cone tip of the conical sealing cover 57 is downward, and the conical sealing cover 57 is a part of the airtight air chamber 7. Upper sealing surface; the top of the temperature isolation part 6 is sealed with a high temperature resistant wave transparent quartz glass 61, the upper surface of the high temperature resistant wave transparent quartz glass 61 is the lower sealing surface of the airtight chamber 7, the lower part of the temperature isolation part 6 A purge gas passage 62 surrounding the high-temperature resistant wave-tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com