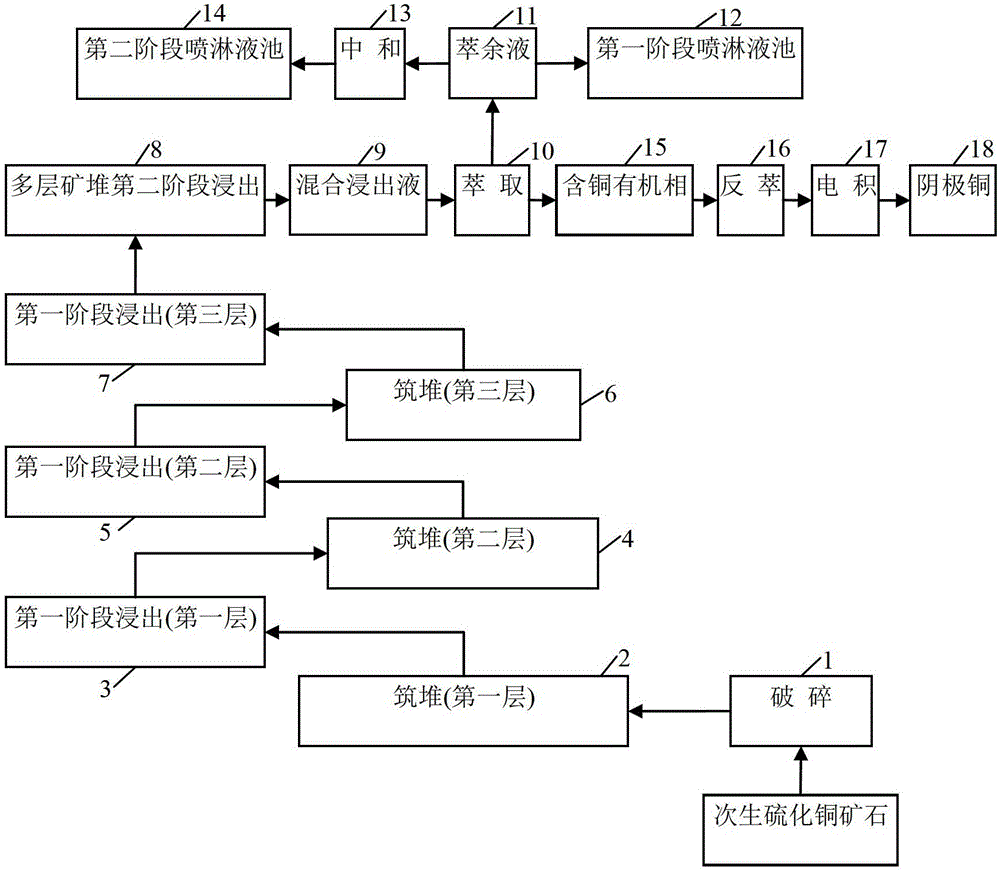

A two-stage bioheap leaching method for secondary copper sulfide ore

A technology for copper sulfide ore and bioreactor, applied in the field of hydrometallurgy, can solve the problems of inefficient leaching, inability to utilize heat, low leaching efficiency, etc., and achieve the advantages of improving comprehensive utilization rate, easy control of process parameters, and reducing operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The copper grade in a certain secondary copper sulfide ore is 0.42%, and the copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as chalcopyrite and chalcopyrite; the content of pyrite is relatively high ( 5-9%), copper minerals and pyrite are closely symbiotic; gangue minerals are mainly quartz, and the content of acid-consuming gangue is low.

[0032] In the mine's two-stage bioheap leaching industrial test, the mined ore was broken to P 80 =50mm, the crushed ore is transported to the storage yard for the first layer of stacking; using the stacking stacking method, a total of 3 layers are built, and the height of each layer is 8m. The acid pit water (acid mine water) produced by this mine is used to prepare the spray liquid required for the first stage leaching. The concentration of sulfuric acid in the spray liquid is 20-25g / L, Fe 3+The concentration is 15-20 / L, and the spray liquid is stored in the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap