A kind of preparation method of ti-nb-fe-o high damping alloy

A technology of ti-nb-fe-o, high damping alloy, applied in the field of high damping alloy and its preparation, can solve the problems of uncontrollable TiO2 loss, relaxation reversibility or relaxation strength decrease, and alloy damping performance deterioration, etc. Achieve precise and controllable components, enhance mechanical properties, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

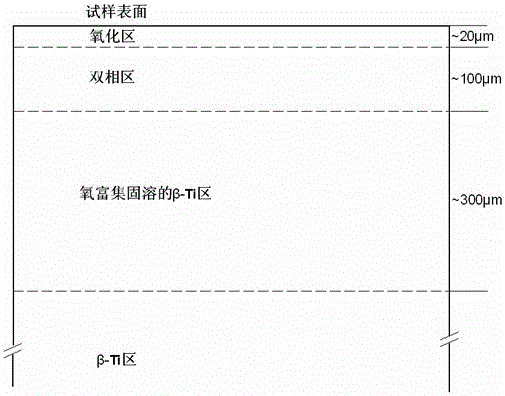

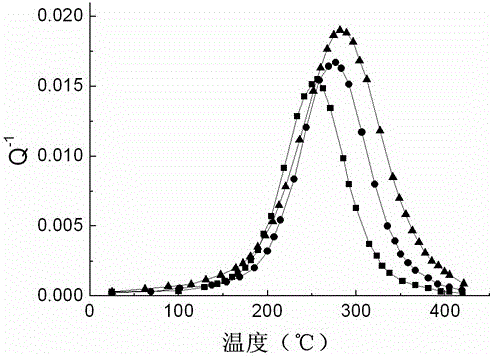

Image

Examples

Embodiment 1

[0028] Example 1: The mass percentage (wt.%) of the alloy composition in the Ti-Nb-Fe-O high damping alloy is: Ti: 74.1, Nb: 15.3, Fe: 10.5, O atom solid solution: 0.10.

Embodiment 2

[0029] Example 2: The mass percentage (wt.%) of the alloy composition in the Ti-Nb-Fe-O high damping alloy is: Ti: 70.42, Nb: 12.4, Fe: 17.1, O atom solid solution: 0.08.

Embodiment 3

[0030] Example 3: The mass percentage (wt.%) of the alloy composition in the Ti-Nb-Fe-O high damping alloy is: Ti: 64.74, Nb: 11.0, Fe: 24.2, O atom solid solution: 0.06.

[0031] The concrete preparation steps of above-mentioned embodiment are as follows:

[0032] 1. Matrix alloy melting

[0033] According to the ratio of Ti-Nb-Fe matrix alloy, the Ti-Nb master alloy is first melted in a high-vacuum arc melting furnace with a vacuum degree of 0.01Pa and argon protection, and then Fe is added to melt into a Ti-Nb-Fe matrix alloy.

[0034] 2. Vacuum heat treatment of base alloy

[0035] The obtained Ti-Nb-Fe matrix alloy is placed in a vacuum heat treatment furnace with a vacuum degree of 0.01Pa, the vacuum heat treatment temperature is 900°C, and the heat treatment time is 1 hour, so that the Ti-Nb-Fe matrix alloy is fully homogenized.

[0036] 3. Cold rolling deformation treatment of base alloy

[0037] The homogenized Ti-Nb-Fe matrix alloy is cold-rolled and deformed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com