Water-based rust preventer and preparation method and application thereof

A water-based anti-rust agent and rolling line technology, which is applied in the field of steel surface treatment, can solve the problems that cannot fully meet the anti-rust requirements, need several hours or even a day, and have no high-temperature anti-rust methods to achieve good economy and use The method is simple and has the effect of delaying surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of water-based antirust agent of the present invention comprises following concrete steps:

[0026] (1) Determine the dosage of each component;

[0027] (2) Add gelatin to water and stir until it dissolves completely. The mass-to-volume ratio of gelatin to water (g:L) is 1:8-15; add alum to water and stir until it is completely dissolved. L) is 1:20~40; add sodium dodecylsulfonate into water and stir well until it dissolves completely, the mass-volume ratio of solid to liquid (g:L) is 1:6~15;

[0028] (3) Mix the above three solutions with water-soluble silicone oil evenly;

[0029] (4) Add water to constant volume to obtain the water-based antirust agent.

[0030] Gelatin is difficult to dissolve in water at normal temperature and pressure. The dissolution method adopted in this technical solution is to first soak gelatin at room temperature for 10-30 minutes, and then fully stir in a constant temperature water bath at 65-70°C until it is compl...

Embodiment 1

[0038] The formula of water-based antirust agent is: 30g / L gelatin, 3g / L alum, 20g / L sodium dodecylsulfonate, 20g / L water-soluble silicone oil, and the balance is water.

[0039] First soak 30g of gelatin at room temperature for 10min, add it into 250mL of water, and stir in a constant temperature water bath at 65°C until completely dissolved. Add 3g of alum into 120mL of water and stir until it is completely dissolved, add 20g of sodium dodecylsulfonate into 200mL of water and stir until it is completely dissolved. Thoroughly mix the above three solutions with 20 g of water-soluble silicone oil, add water to make the volume to 1 L, and obtain the water-based antirust agent.

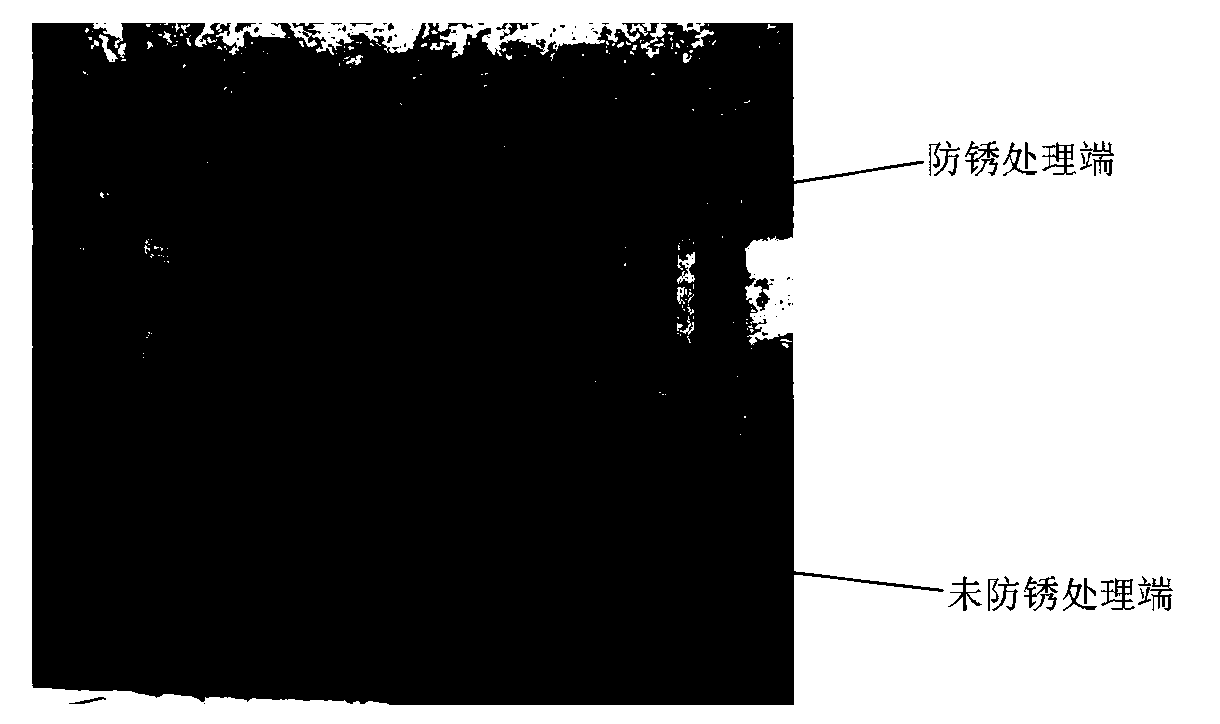

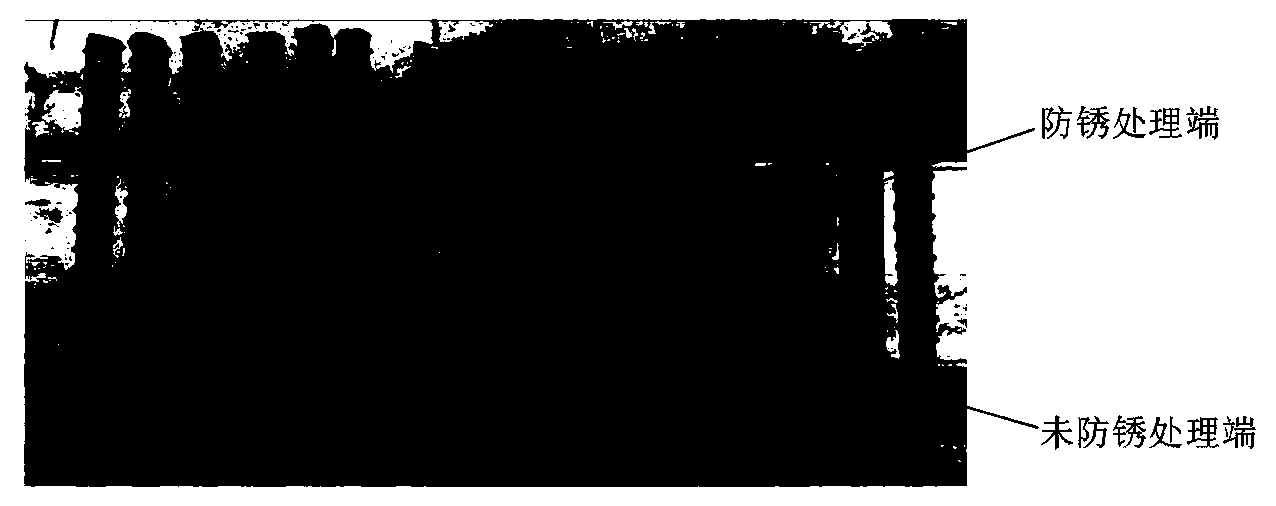

[0040] The hot-rolled ribbed steel bar with a surface temperature of 200 ° C is completely immersed in the anti-rust agent for 10 seconds. After the anti-rust agent dries, a bright anti-rust film is formed on the surface of the steel bar.

Embodiment 2

[0042] The formula of water-based antirust agent is: 30g / L gelatin, 3g / L alum, 20g / L sodium dodecylsulfonate, 20g / L water-soluble silicone oil, and the balance is water.

[0043] Soak 30g of gelatin at room temperature for 20min, add 300mL of water, and stir in a constant temperature water bath at 65°C until completely dissolved; add 3g of alum in 100mL of water and stir until completely dissolved; add 20g of sodium dodecylsulfonate into 300mL of water Stir well until completely dissolved. Thoroughly mix the above three solutions with 20 g of water-soluble silicone oil, add water to make the volume to 1 L, and obtain the water-based antirust agent.

[0044] The hot-rolled ribbed steel bar with a surface temperature of 200 ° C is completely immersed in the anti-rust agent for 10 seconds. After the anti-rust agent dries, a bright anti-rust film is formed on the surface of the steel bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com