Passive self-flow control water injection system

A flow control and water injection system technology, applied in nuclear power generation, reactors, and greenhouse gas reduction, can solve the problems of large changes in water injection flow before and after stages, inability to cope with injection, and low utilization of IVR water sources, etc., to achieve high system reliability, The effect of stabilizing injection flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

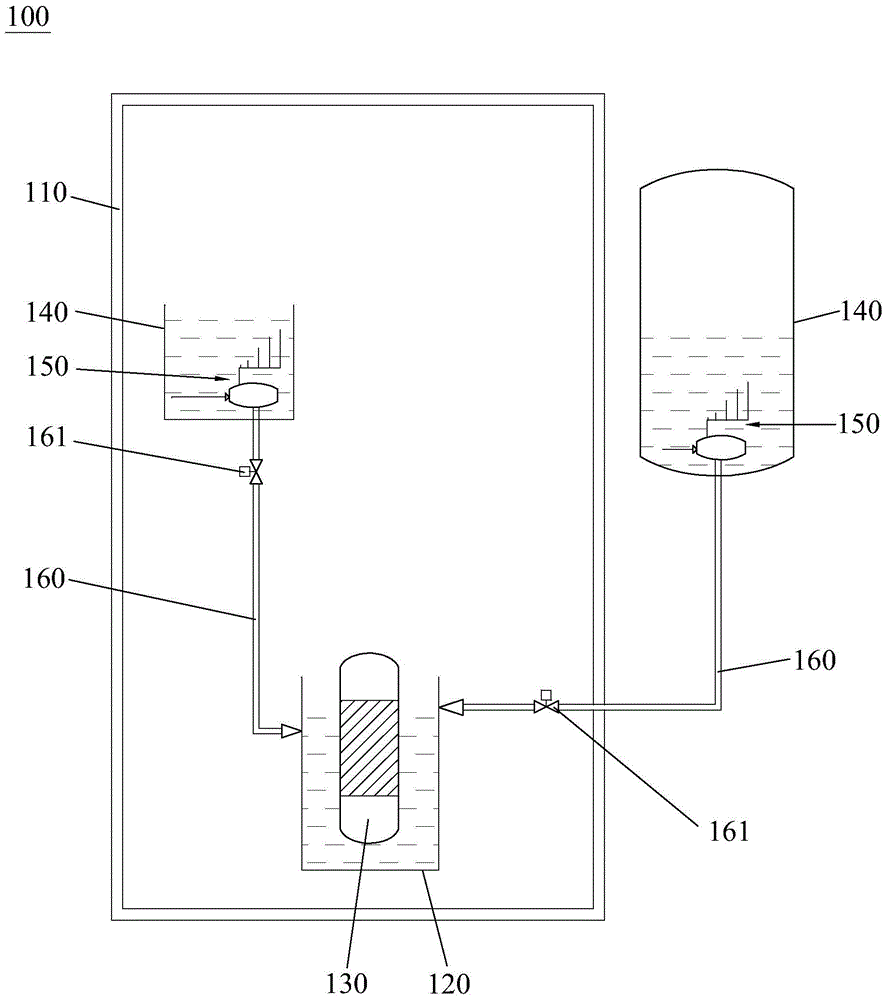

[0028] like figure 1 As shown, the passive self-flow control water injection system 100 provided by the present invention is suitable for injecting water into the reactor pit 120 inside the containment vessel 110 , wherein the reactor pit 120 houses a pressure vessel 130 .

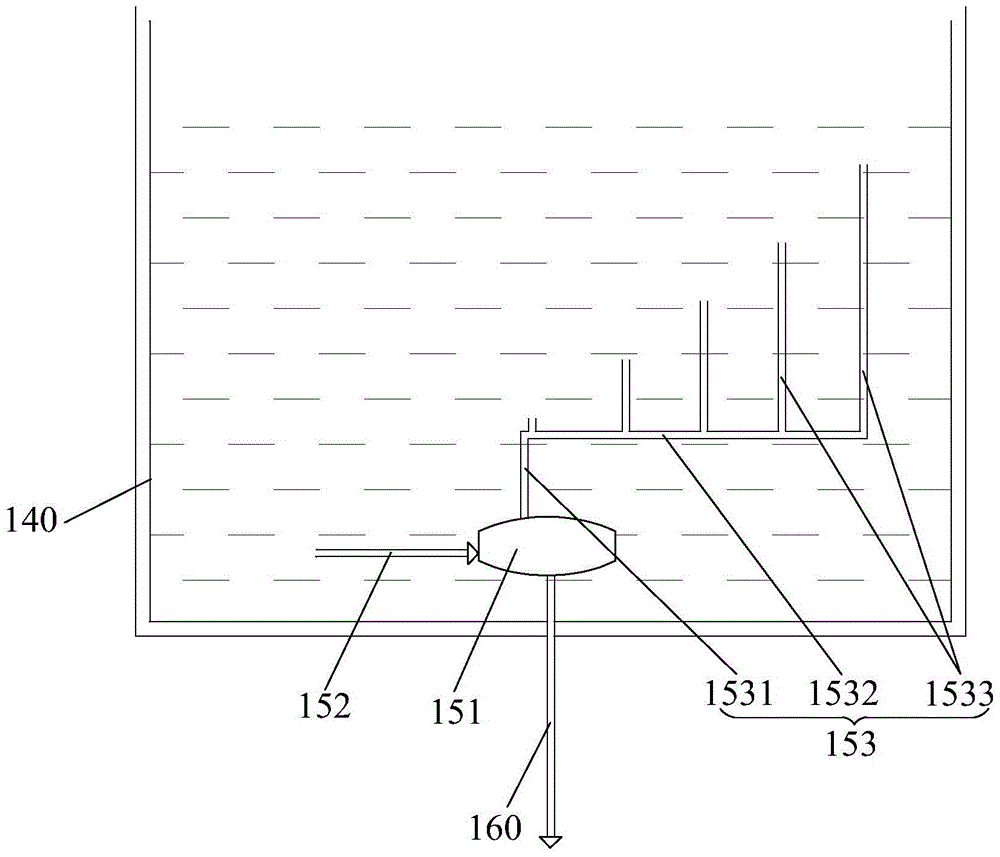

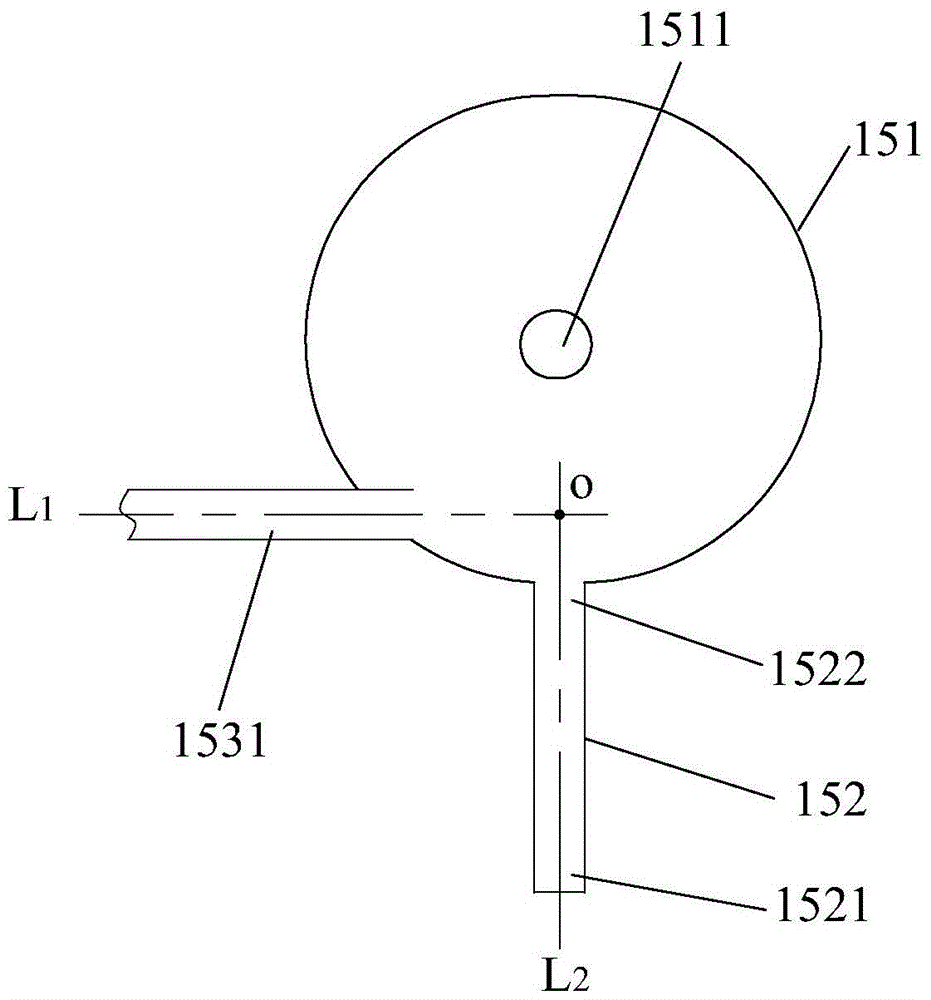

[0029]The passive self-flow control water injection system 100 includes a safety injection tank 140 and a self-flow control device 150, the safety injection tank 140 is arranged inside or outside the containment vessel 110, and the self-flow control device 150 is housed in The safety injection tank 140 is connected to the reactor pit 120 through a water outlet pipe 160; in the event of an accident, driven by the gravity difference or back pressure difference, the cooling water in the safety injection tank 140 passes through the flow control device 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com