Apparatus for rapidly gasifying liquid nitrogen through circulating water bath, and operating method thereof

A technology of circulating water bath and gasification device, which is applied in the method of container discharge, fixed-capacity gas storage tank, gas/liquid distribution and storage, etc. It can reduce investment costs, eliminate pressure fluctuations, and improve security capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

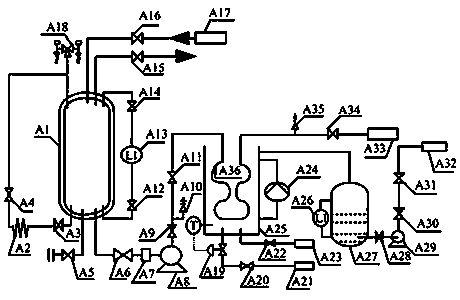

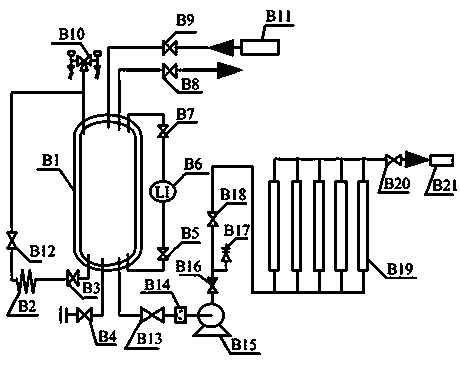

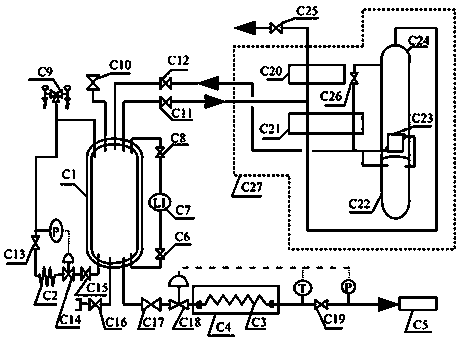

Image

Examples

Embodiment Construction

[0042] The following takes an external supply of 20,000 cubic meters of nitrogen per hour, and the normal pressure of the nitrogen pipe network is 0.5 MPa as an example to illustrate the rapid gasification device for liquid nitrogen in a circulating water bath. Select the pressure-resistant low-temperature liquid nitrogen vacuum tank with a pressure rating of 1.0 MPa and an effective volume of 50 cubic meters, and install the equipment according to image 3 The process shown is installed in place. Assuming that the production of the full low-pressure air separation unit is normal, all the valves of the circulating water bath liquid nitrogen quick gasification device outside the cold box C27 are closed, and then proceed as follows:

[0043] 1. Open the liquid level gauge, pressure gauge, and valve in front of the safety explosion-proof membrane of liquid nitrogen tank C1;

[0044] 2. Open the C11 and C12 valves, and fill the liquid in C1 to above 80% of the liquid level;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com