Shale residual gas content testing system

A test system and residual gas technology, applied to the analysis of materials, instruments, etc., can solve the problems of incomplete measurement of residual gas, difficult gas desorption, gas mixing, etc., to achieve powerful data collection and processing functions, reduce labor intensity, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

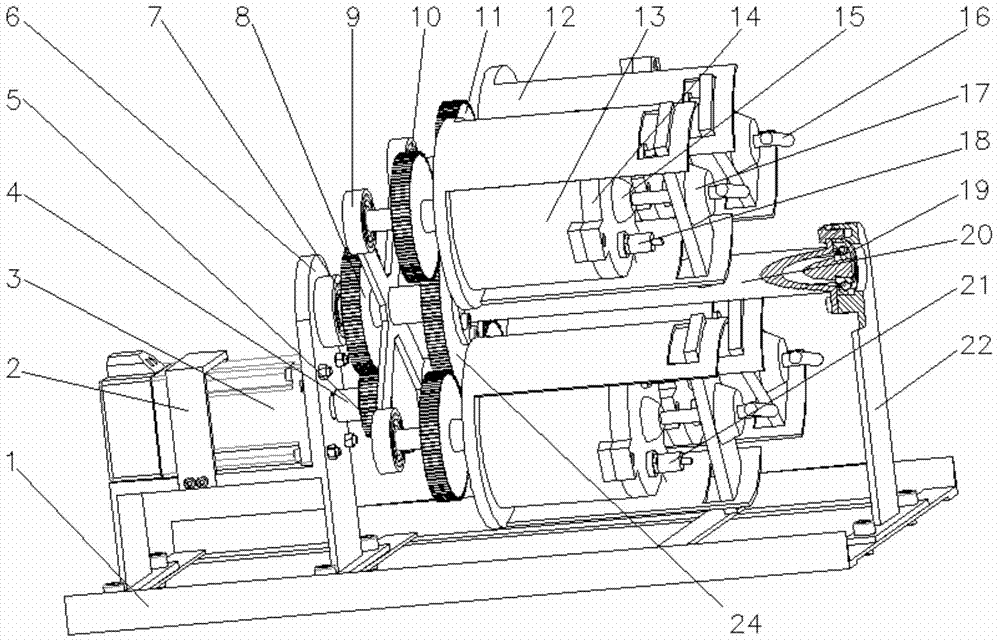

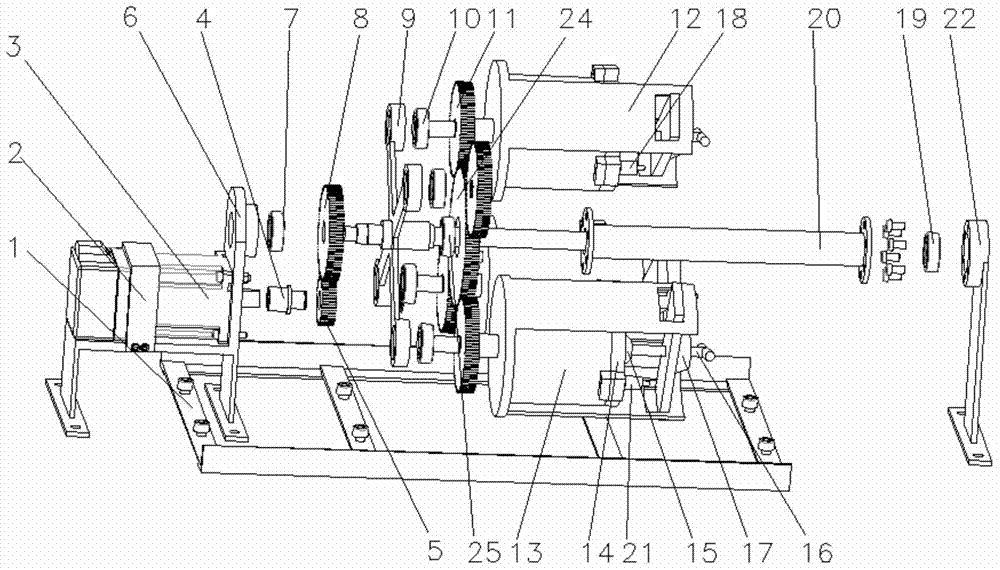

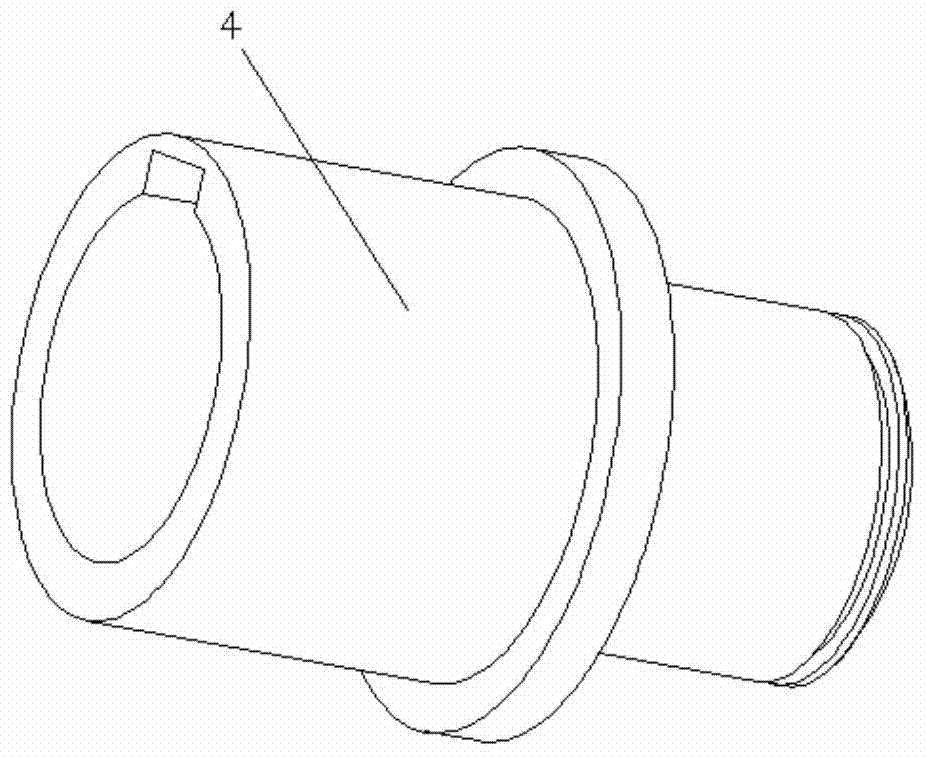

[0050] Embodiment 1: The present invention provides a kind of shale residual gas measurement system, comprises rock sample airtight crushing device, residual gas content measuring mechanism and computer; The structure of described airtight crushing device and residual gas content measuring mechanism is as follows figure 1 , 2 As shown, the device is equipped with a base 1, a fixed piece 2, a motor 3, a motor connecting shaft 4, a small reduction wheel 5, a motor bracket 6, a bearing A 7, a large reduction wheel 8, a planet carrier 9, a bearing D 10, and a planetary wheel 11 , Ball mill holder 12, sealed ball mill, ball mill press block 15, twist handle 16, threaded clamp block 17, bearing B 19, connecting shaft tube 20, right end bracket 22, sealing ring 23, sun gear 24, bearing C 25. The motor 3 is fixed on the motor bracket 6 through the fixing piece 2, the bolt and the motor front flange, and the motor support 6 is connected with the base 1 through the bolt.

[0051] For ...

Embodiment 2

[0058] Embodiment 2: Measurement of residual gas content using a shale residual gas measurement system provided in Embodiment 1. The whole working process of the system is as follows: Figure 6 Shown:

[0059] The process of airtight crushing of the rock sample is as follows: the rock sample is put into each airtight ball milling jar, and the airtight ball milling jar is compressed on the ball milling jar holder 12 through the ball milling jar briquetting block 15 .

[0060] The motor 3 rotates through the flat key to drive the motor connection shaft and the small reduction wheel 5 to rotate, and the small reduction wheel 5 drives the large reduction wheel 8 to rotate through the flat key; the large reduction wheel 8 drives the planet carrier 9 to rotate through the flat key, so the planet carrier 9 and the large The reduction gear 8 rotates at the same speed; the planet carrier 9 drives the planetary gear 11 to revolve; the sun gear 24 is connected to the connecting shaft cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com