Detection liquid for detecting corrosion resistance of surface passivation film of tinned steel plate

A technology of tin-plated steel plate and passivation film, which is applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, instrument, etc., which can solve the problems of long test time, inconvenient quality management of tin-plated steel plate, and no effective method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 One kind detects the corrosion resistance of tinned steel plate surface passivation film

[0037] 1. Detection solution formula

[0038] The formula and composition range of the detection solution of this embodiment

[0039] ingredients

parts by weight

[0040] Sulfuric acid (mineral acid)

0.1

0.1

0.1

Potassium ferricyanide (complexing agent)

0.05

water

99.65

[0041] Remarks: The concentration of sulfuric acid is 98wt%.

[0042] 2. Detection solution preparation process:

[0043] Dissolve the above-mentioned amount of sulfuric acid in water, then add the above-mentioned amount of citric acid, ferric chloride, and potassium ferricyanide in sequence, and stir evenly before use.

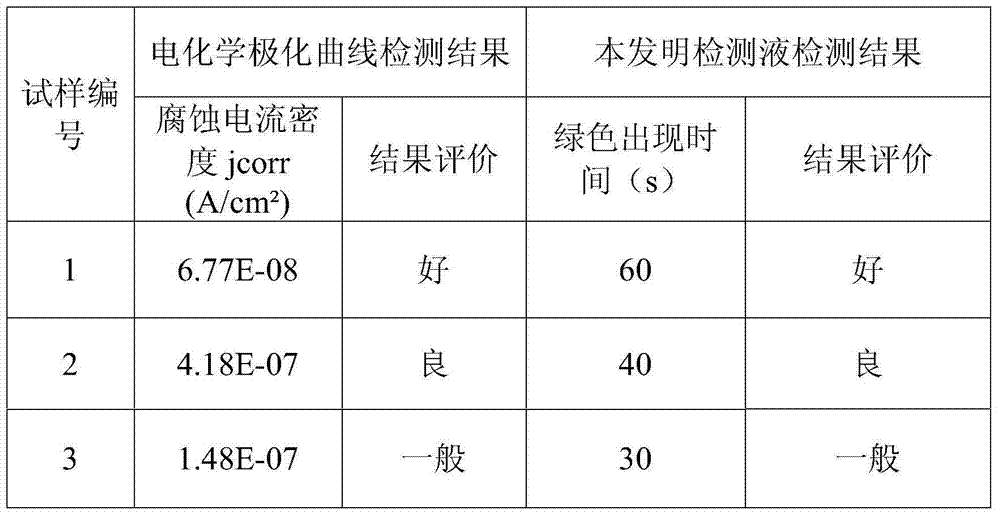

[0044] 3. Use the detection solution to detect the corrosion resistance of the tinned steel sheet samples (sample 1-3) with passivation film ...

Embodiment 2

[0054] Embodiment 2 One kind detects the corrosion resistance of the passive film on the surface of tin-plated steel plate

[0055] 1. Detection solution formula

[0056] The formula and composition range of the detection solution of this embodiment

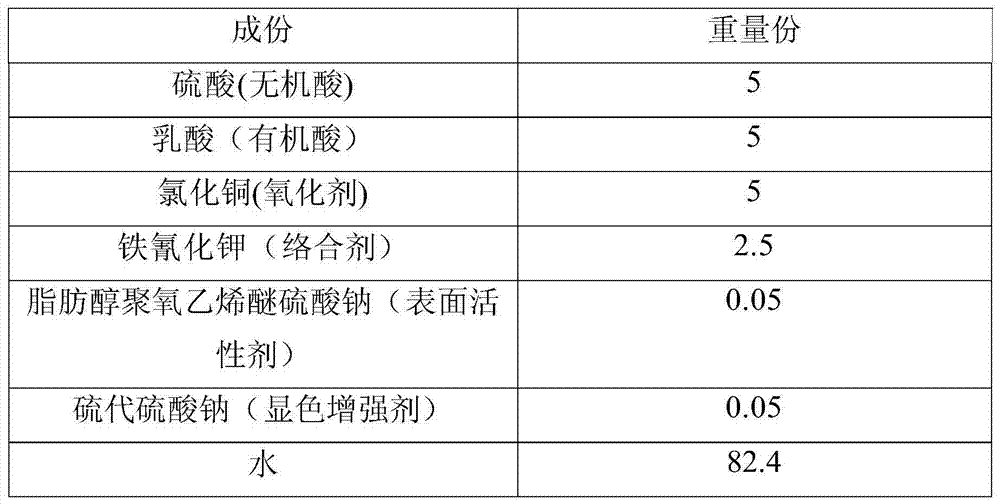

[0057]

[0058] Remarks: the concentration of sulfuric acid is 98wt%

[0059] 2. Detection solution preparation process:

[0060] Dissolve the above-mentioned amount of sulfuric acid in water, then add the above-mentioned amount of lactic acid, copper chloride, potassium ferricyanide, and sodium thiosulfate into the solution in sequence, stir and dissolve fully, then add the above-mentioned amount of fatty alcohol polyoxyethylene ether Sodium sulfate, and stir well, set aside.

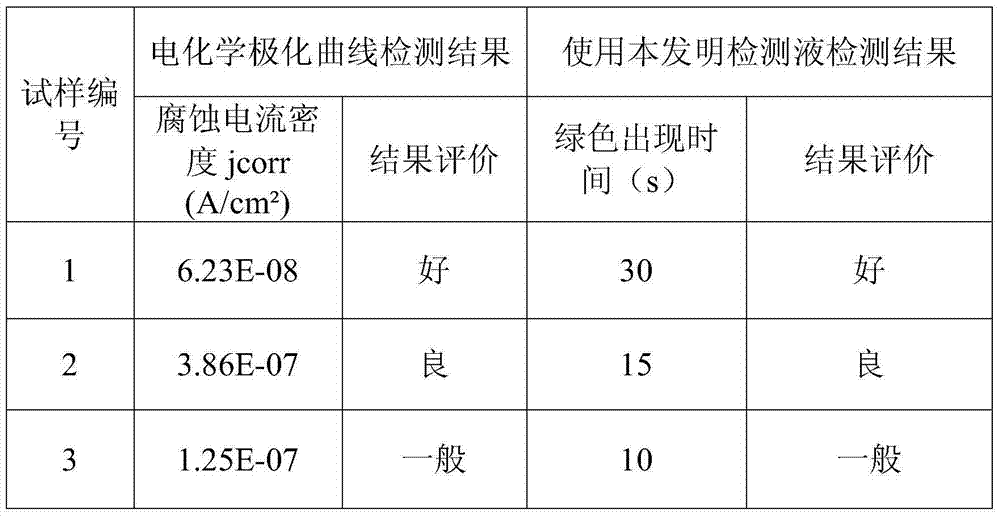

[0061] 3. Use the detection solution to detect the corrosion resistance of tin-plated steel samples (sample 1-3) with passivation films on the surface from 3 manufacturers (such as Baosteel, Pacific Ocean, and Zhongyue), and the passivation films ar...

Embodiment 3

[0071] Embodiment 3 One kind detects the corrosion resistance of tinned steel plate surface passivation film

[0072] 1. Detection solution formula

[0073] The formula and composition range of the detection solution of this embodiment

[0074]

[0075] Remarks: the concentration of sulfuric acid is 98wt%; the concentration of hydrochloric acid is 36wt%.

[0076] 2. Detection solution preparation process:

[0077] Dissolve the above amount of sulfuric acid and hydrochloric acid in water, then add the above amount of glycolic acid, ferric chloride, potassium ferricyanide, and disodium ethylenediamine tetraacetate into the solution in sequence, stir and dissolve fully, and then add the calculated amount Fatty alcohol polyoxyethylene ether sodium sulfate and octylphenol polyoxyethylene ether, and stir well, set aside.

[0078] 3. use the detection solution to detect the corrosion resistance of the tin-plated steel sheet samples with passivation film on the surface from two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com