Power transformation cabinet with fault self-checking function

A fault self-checking, substation cabinet technology, applied in the substation field, can solve the problems of increasing the difficulty of maintenance and repair, high density of substation cabinet equipment, and achieve the effect of wide influence, strong real-time performance, and avoiding machine damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

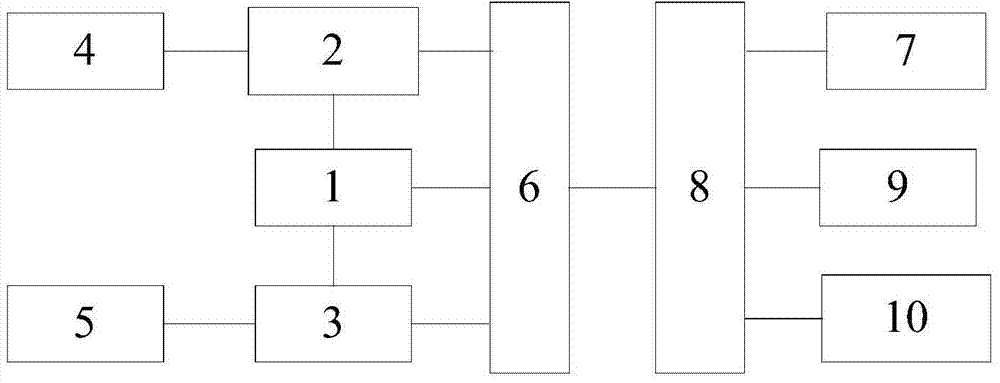

[0017] refer to figure 1 , a power transformer cabinet with a fault self-checking function proposed by the present invention, comprising: a transformer module 1, a high-voltage module 2, a low-voltage module 3, a first external terminal 4, a second external terminal 5, a fault detection module 6, a storage Module 7, control module 8, alarm module 9, display module 10 and independent power supply.

[0018] Transformer module 1 is respectively connected to high-voltage module 2 and low-voltage module 3 to convert high-voltage and low-voltage electricity, the first external terminal 4 is connected to high-voltage module 2 for external transmission or reception of high-voltage power, and the second external terminal 5 is connected to low-voltage module 3 Used for external transmission or reception of low-voltage electricity. Specifically, when the high-voltage module 2 receives high-voltage electricity through the first external terminal 4, the transformer module 1 converts the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com