Thermomagnetic power generation system driven by linear compressor

A technology for linear compressors and power generation systems, which is applied to thermoelectric devices utilizing thermal changes in magnetic permeability, etc., can solve problems such as limited high temperature, complicated installation of piston pumps and flow channel seals, and restrictions on the application of high Curie point soft magnetic materials. , to achieve the effect of quiet operation, simple installation, safe and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

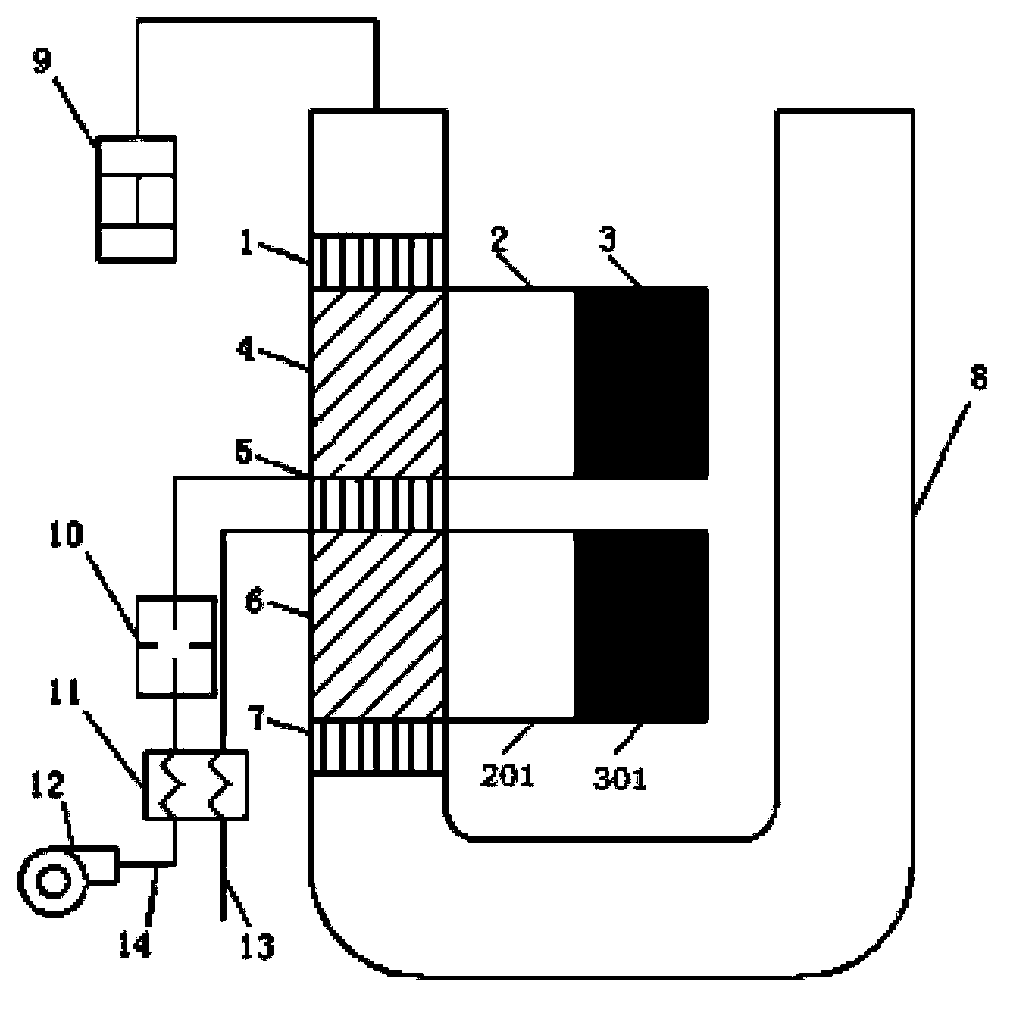

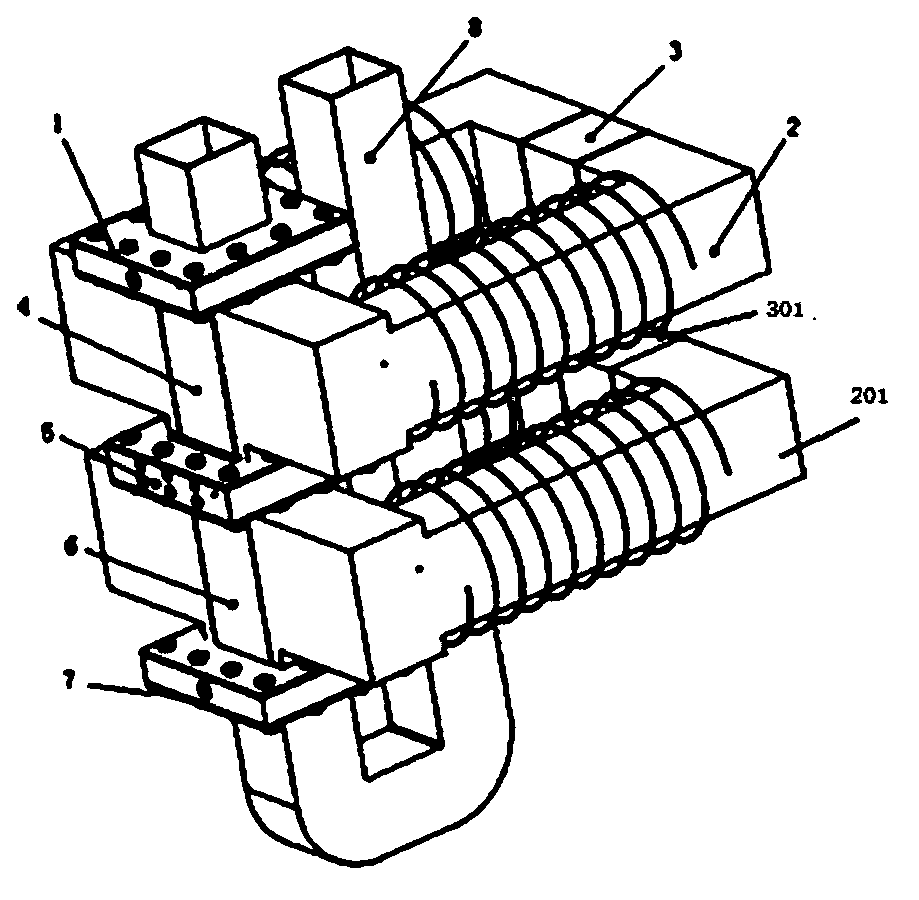

[0049] Picture 1-1 It is a schematic structural diagram of a thermomagnetic power generation system (embodiment 1) driven by a linear compressor of the present invention.

[0050] Figure 1-2 for Picture 1-1 As can be seen from the figure, the thermomagnetic power generation system driven by the linear compressor of the present embodiment 1; the heat source supply system provides the required heat for the high temperature heat exchanger of the thermomagnetic generator; the thermomagnetic generator utilizes fluid The alternating flow converts the thermal energy of the high temperature heat exchanger into electrical energy;

[0051] Thermomagnetic generators include:

[0052] A heat exchange assembly composed of the first room temperature heat exchanger 1, the first soft magnetic body 4, the high temperature heat exchanger 5, the second soft magnetic body 6 and the second room temperature heat exchanger 7 connected in sequence;

[0053] A pair of bow-shaped upper magnetize...

Embodiment 2

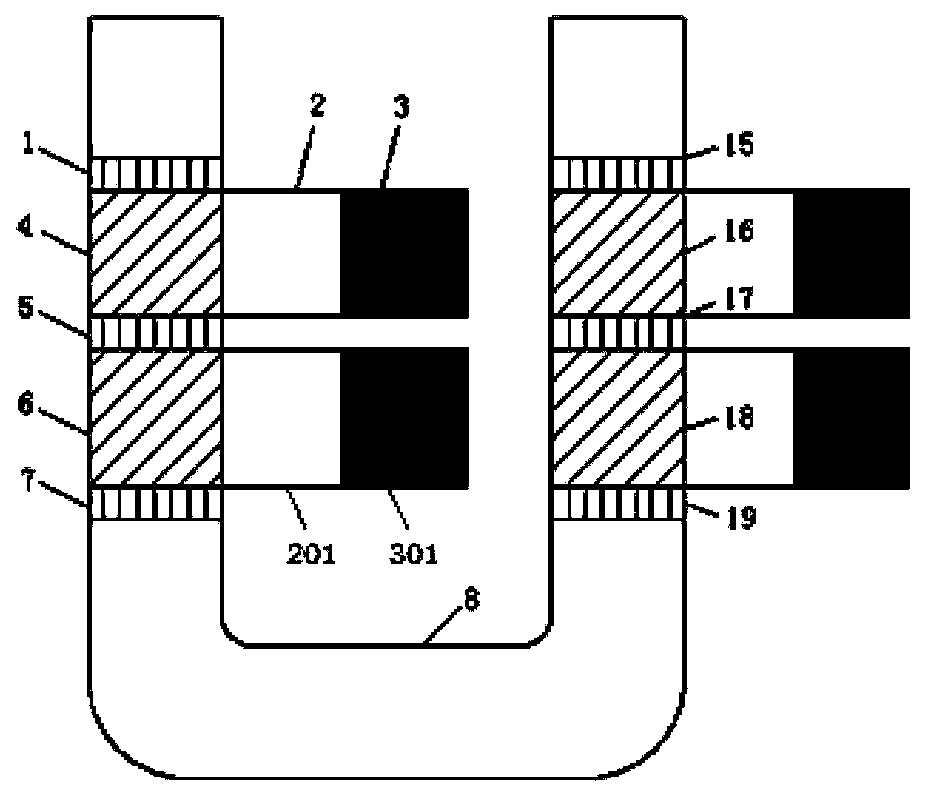

[0066] figure 2 It is a schematic structural diagram of a thermomagnetic power generation system (Example 2) driven by a linear compressor of the present invention.

[0067] In order to improve efficiency and make full use of the fluid reciprocating motion provided by the linear compressor, a symmetrical arrangement is designed on the right side of the U-shaped flow channel 8 and the left side. composition. When the fluid flows counterclockwise, it first cools down through the first room temperature heat exchanger 1, then cools the first soft magnetic body 4, then heats up in the first high temperature heat exchanger 5, then heats the second soft magnetic body 6, and then cools down by the second room temperature The heat exchanger 7 cools down, and in the flow channel on the right, the fourth room temperature heat exchanger 19 cools down first, then cools the fourth soft magnetic body 18, then heats up by the second high temperature heat exchanger 17, heats the third soft m...

Embodiment 3

[0069] image 3 It is a schematic structural diagram of a thermomagnetic power generation system (embodiment 3) driven by a linear compressor of the present invention.

[0070]In this example, the soft magnets in the left and right channels are divided into several sections according to the height of the Curie point, and the left and right symmetrical soft magnets are connected in a magnetic circuit, so that when the fluid reciprocates, the symmetrical soft magnets are simultaneously Heating and cooling causes a greater amount of flux change in the magnetic circuit, resulting in a greater current flow. Due to the limited amplitude of fluid oscillation, and the heat transfer fluid is heat transfer oil with a relatively small heat penetration depth, it is difficult for the soft magnet to fully exchange heat. In this example, the soft magnet is divided into several sections according to the Curie point, which can ensure Within the oscillation amplitude of the fluid, there is eno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com