A High-Precision On-line Measuring Method of Tool Offset

A technology of deviation amount and tool, which is applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing equipment, etc., and can solve problems such as non-compliance, tool eccentric beating, and unstable process environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

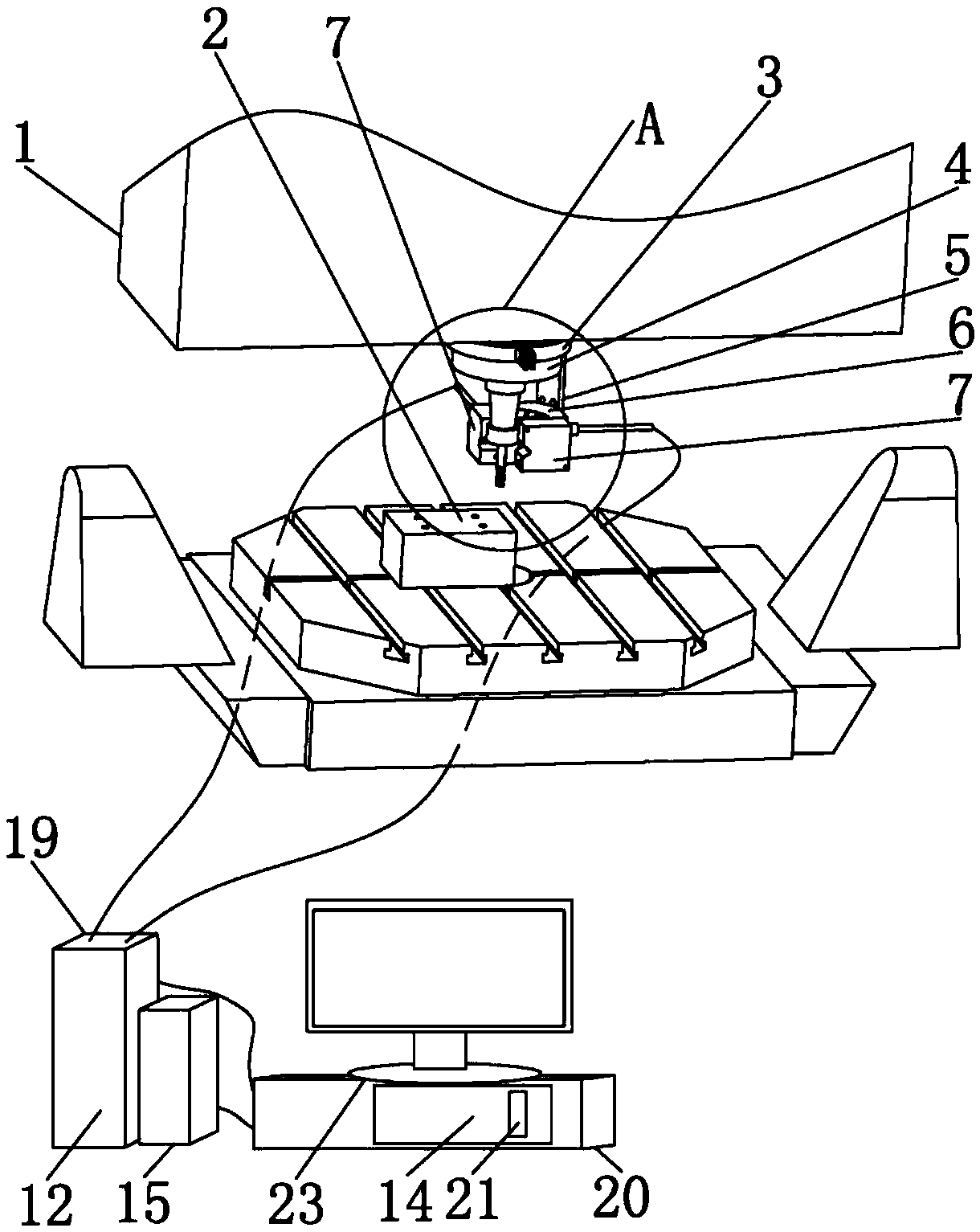

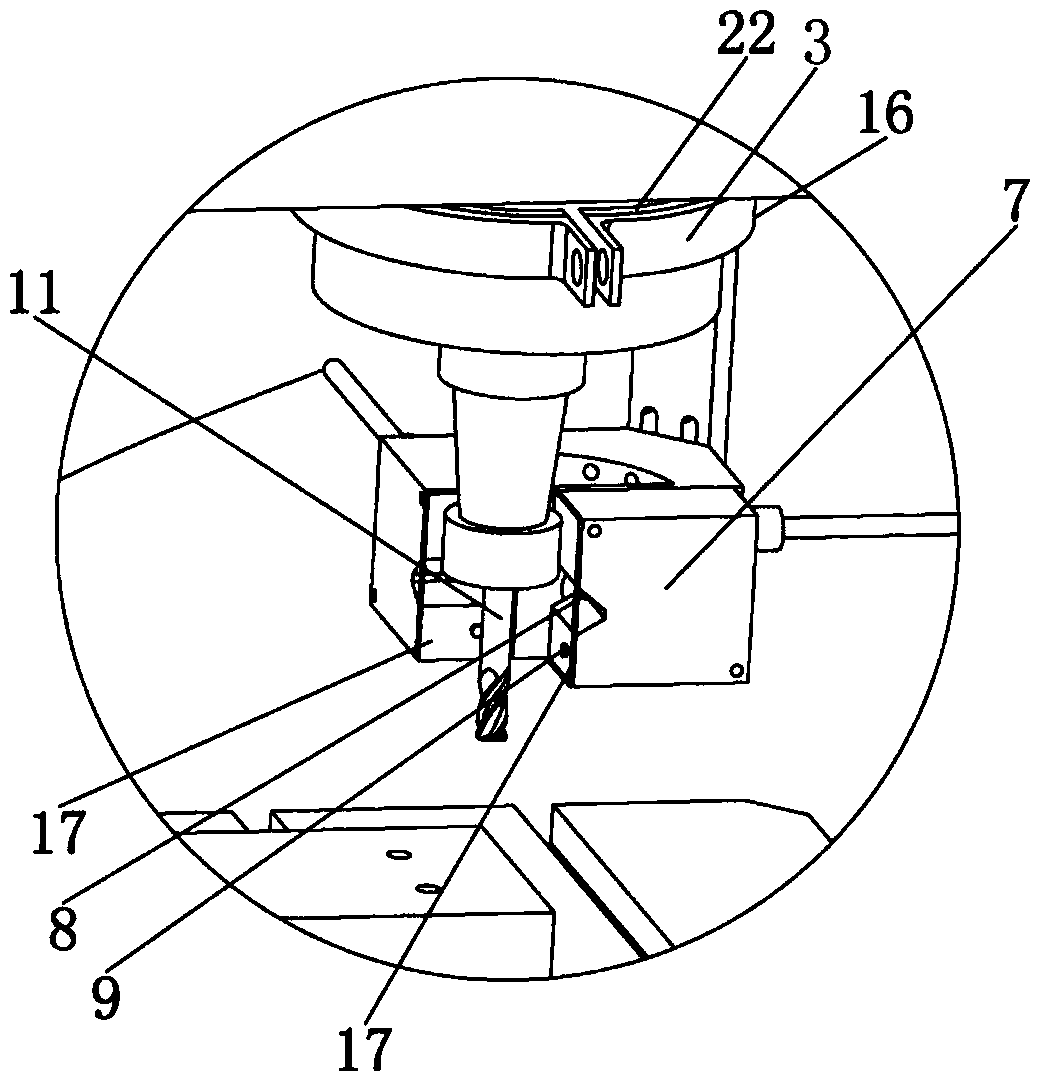

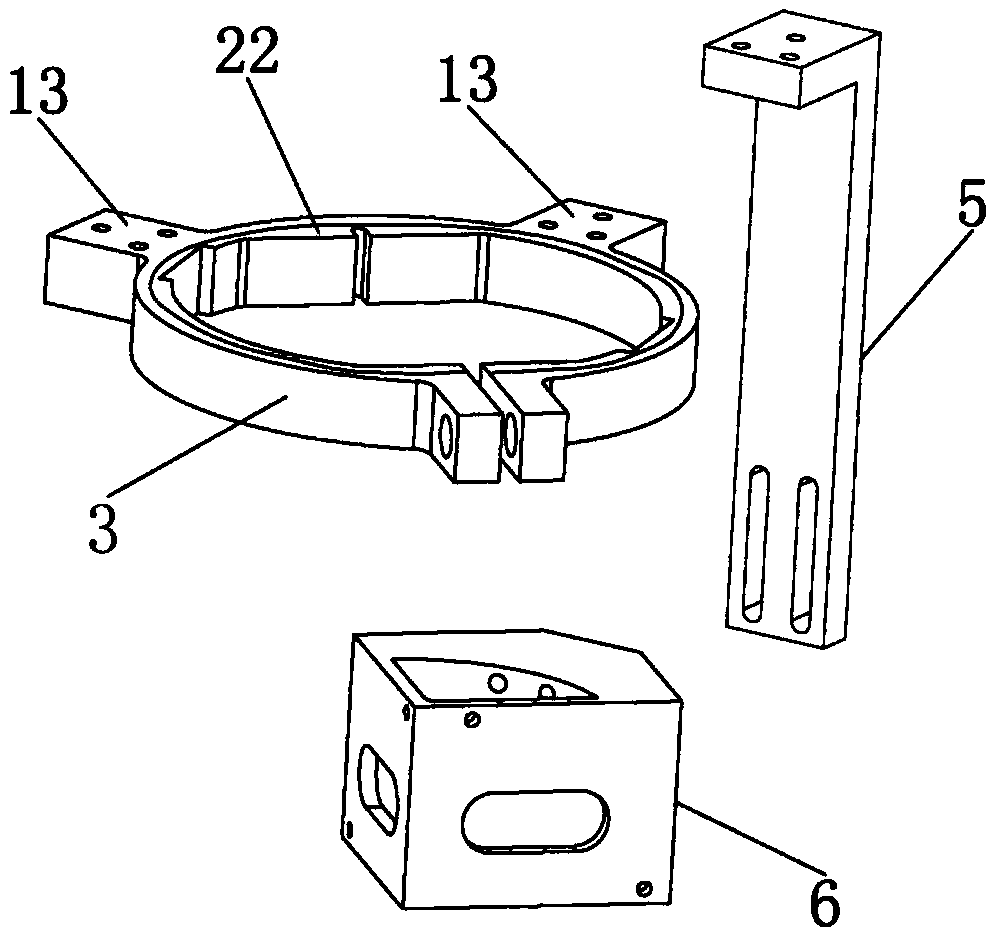

[0044] like Figure 1 to Figure 3 As shown, a high-precision online measuring device for tool deviation includes a clamping mechanism 16 fixedly installed on the spindle head 4 of the machine tool 1. A laser displacement measuring device 19 is installed on the clamping mechanism 16, and the laser The displacement measuring device 19 is connected with a data acquisition and processing device 20 for receiving and processing the signals sent by it. The laser displacement measuring device 19 includes more than two laser measuring heads 7, and the laser measuring heads 7 are all installed on the clamping mechanism 16. Each laser measuring head 7 is provided with a laser transmitter 9 and a laser receiver 8. The laser line emitted by the laser transmitter 9 is reflected on the measured surface of the tool and received by the laser receiver 8. There is a laser measuring The laser line emitted by the head 7 is parallel to the X axis of the machine tool 1 , and the laser line emitted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com