Azeotropic distillation and normal distillation combined process for recycling butanol and butyl acetate

A technology of butyl acetate and azeotropic distillation, which is applied in the preparation of carboxylic acid esters, organic compounds, oxygenated compounds, etc., can solve the problems of energy waste and high energy consumption, and achieve the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

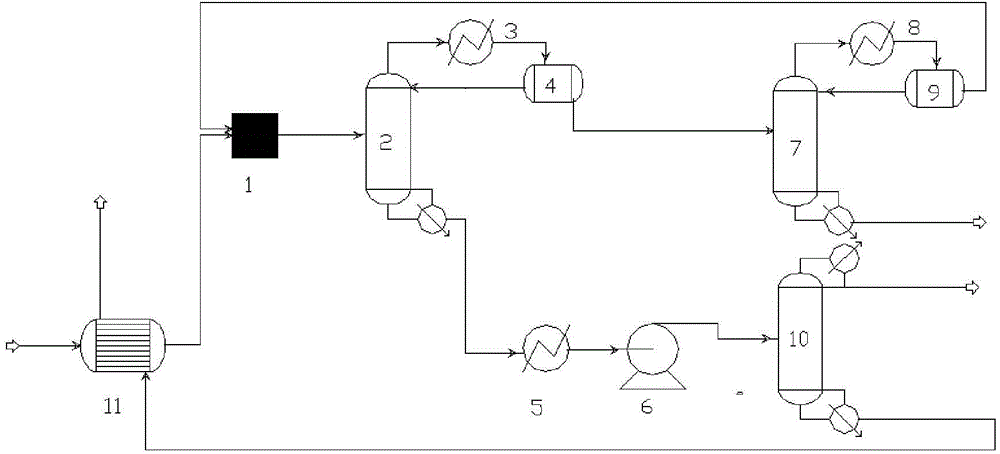

Embodiment 1

[0035] The raw material solution containing butanol, butyl acetate and water at a temperature of 20°C is transported to the heat exchanger 11 through a pipeline at a flow rate of 1300kg / h, and is preheated after heat exchange with the bottom liquid of the third rectification column 10. After heating to 70°C, the raw material liquid is transported to the mixer 1, and after being mixed with the raw material liquid from the second phase separator 9, it is fed from the middle and upper part of the first rectification tower 2, and the tower of the first rectification tower 2 The number of plates is 38, the operating pressure is normal pressure, and the tower kettle is heated by a reboiler. The steam in the first rectification tower 2 is condensed by the first cooler 3 and then sent to the first phase separator 4 for phase separation. After that, the light phase is returned to the first rectification tower 2, and the heavy phase is sent to the second rectification tower 7. In the fi...

Embodiment 2

[0037]The raw material solution containing butanol, butyl acetate and water at a temperature of 30°C is transported to the heat exchanger 11 through a pipeline at a flow rate of 1000kg / h, and is preheated after heat exchange with the bottom liquid of the third rectification column 10. After heating to 72°C, the raw material liquid is transported to the mixer 1, and after being mixed with the raw material liquid from the second phase separator 9, it is fed from the middle and upper part of the first rectification tower 2, and the tower of the first rectification tower 2 The number of plates is 38, the operating pressure is normal pressure, and the tower kettle is heated by a reboiler. The steam in the first rectification tower 2 is condensed by the first cooler 3 and then sent to the first phase separator 4 for phase separation. After that, the light phase is returned to the first rectification tower 2, and the heavy phase is transported to the second rectification tower 7. In ...

Embodiment 3

[0039] The raw material solution containing butanol, butyl acetate and water at a temperature of 22°C is transported to the heat exchanger 11 through a pipeline at a flow rate of 800kg / h, and is preheated after heat exchange with the bottom liquid of the third rectifying tower 10. Heat it to 75°C, then transport the raw material liquid to the mixer 1, mix it with the raw material liquid from the second phase separator 9, and feed it from the middle and upper part of the first rectification tower 2, the tower of the first rectification tower 2 The number of plates is 38, the operating pressure is normal pressure, and the tower kettle is heated by a reboiler. The steam in the first rectification tower 2 is condensed by the first cooler 3 and then sent to the first phase separator 4 for phase separation. After that, the light phase is returned to the first rectification tower 2, and the heavy phase is transported to the second rectification tower 7. In the first rectification towe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap