Butadiene-isoprene co-polymer rubber and preparation method thereof

A technology of isoprene and butadiene, which is applied in the field of butadiene-isoprene copolymer rubber and its preparation, can solve the problems of difficult to use at low temperature, loss of elasticity, poor elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

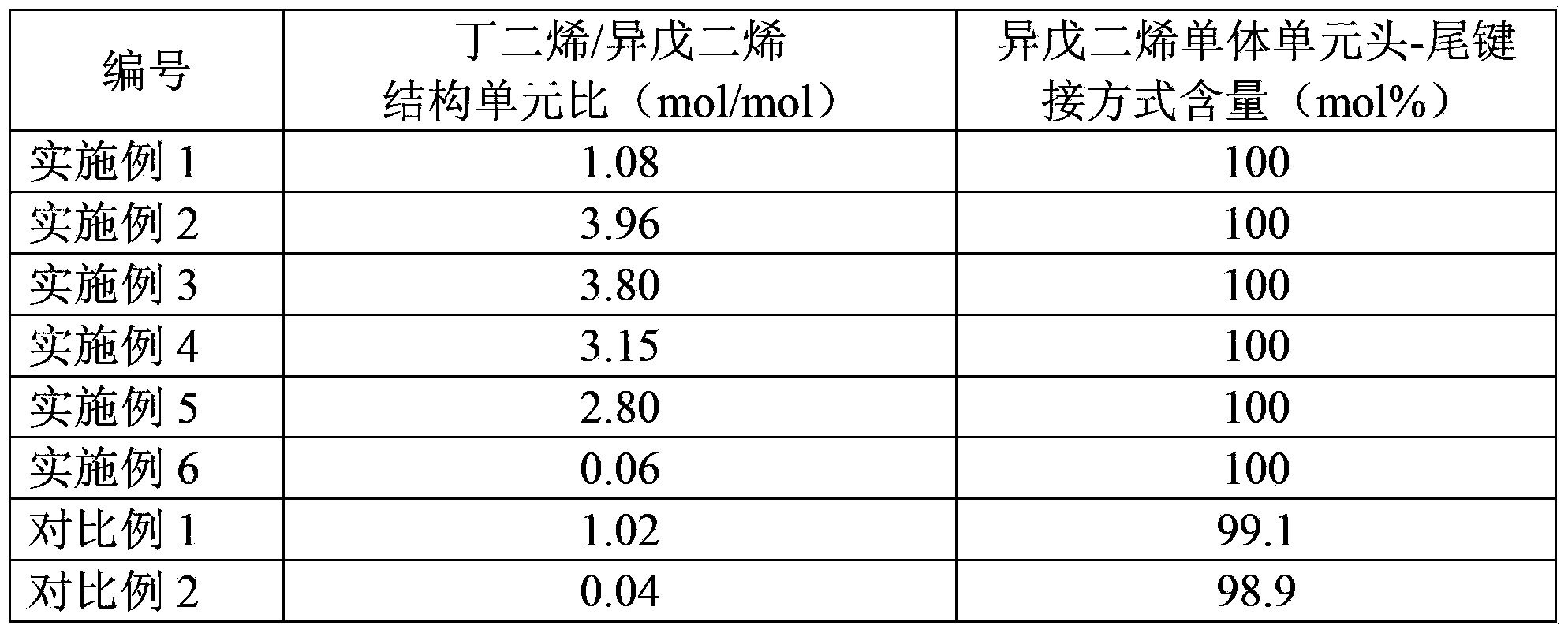

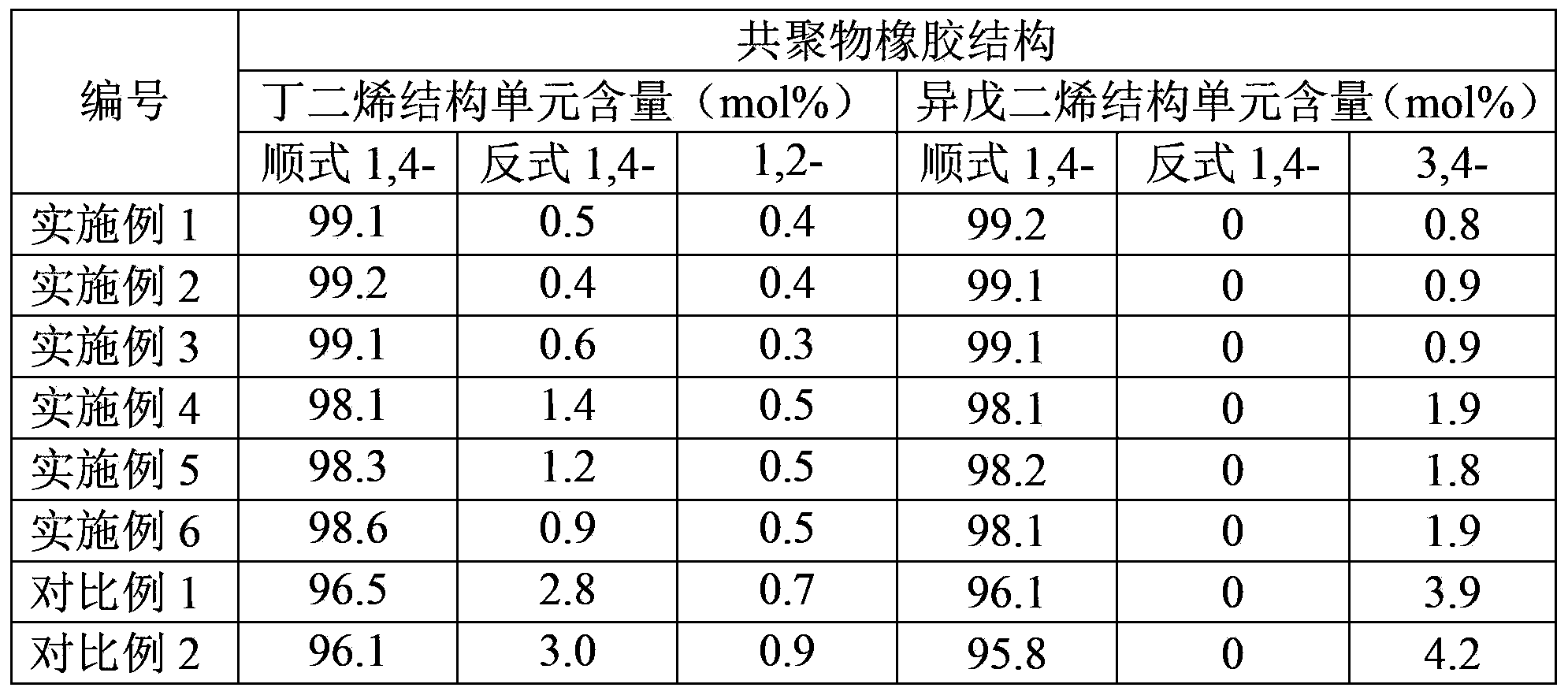

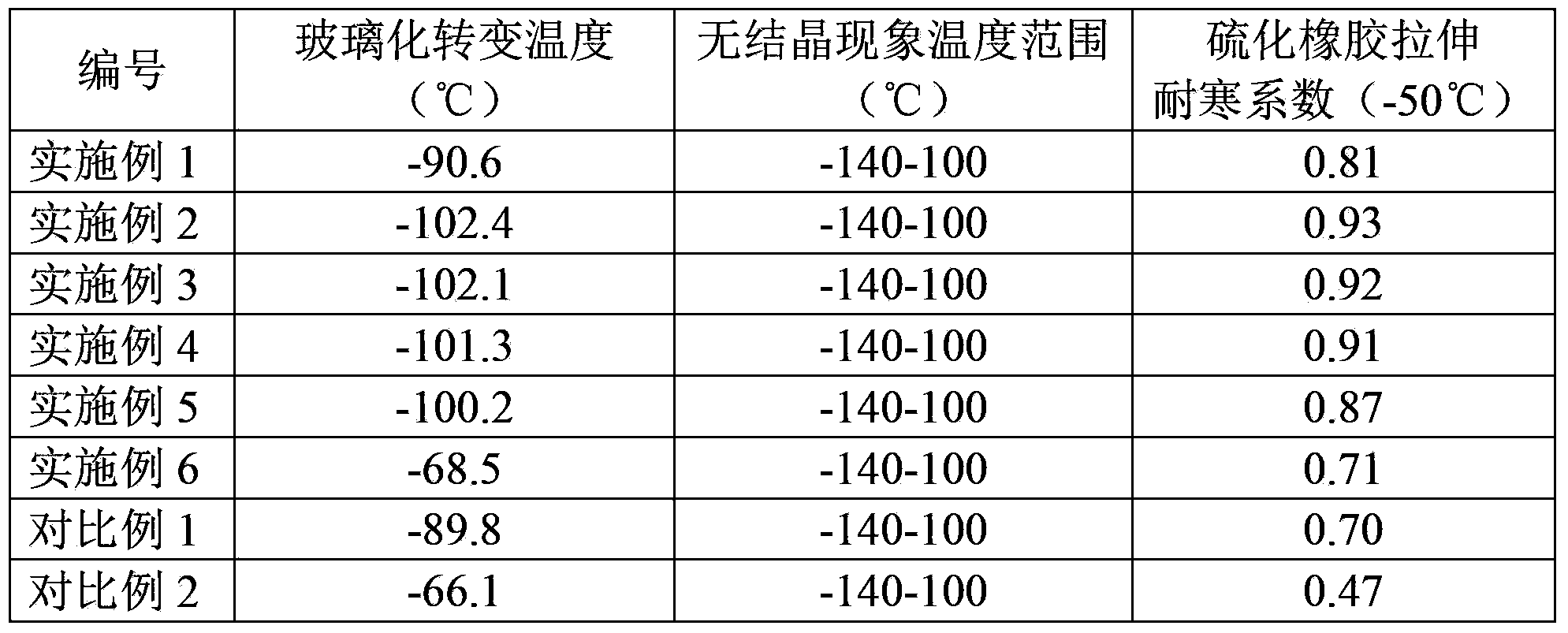

Examples

Embodiment 1

[0071] This example is used to illustrate the preparation method of the butadiene-isoprene copolymer rubber of the present invention.

[0072] (1) Catalyst preparation. Under the protection of nitrogen, add 4000ml hexane, 50ml concentration of 0.50mol / L neodymium neodecanoate solution, 56g butadiene and 1g neodecanoic acid to the dry aging kettle; then add 150ml concentration of 0.5mol / L Chlorodiethylaluminum solution, aged at 10°C for 15 minutes; then added 270ml of triisobutylaluminum solution with a concentration of 1.14mol / L, and continued to age at 10°C for 30h to obtain a homogeneous catalyst C1 . The molar ratio of each component in C1 is neodymium neodecanoate: triisobutylaluminum: diethylaluminum monochloride: butadiene: neodecanoic acid=1:12.3:3.0:41:0.23.

[0073] (2) Butadiene-isoprene copolymerization. Under the protection of nitrogen, add 2000g hexane, 125g butadiene, 125g isoprene and 85ml catalyst C1 to the polymerization kettle at 20°C, in which neodecanoat...

Embodiment 2

[0076] This example is used to illustrate the preparation method of the butadiene-isoprene copolymer rubber of the present invention.

[0077](1) Catalyst preparation. Under the protection of nitrogen, add 3500ml hexane, 100ml concentration of 0.23mol / L neodymium neodecanoate solution, 90g isoprene and 3g neodecanoic acid to the dry aging kettle and mix; then add 160ml concentration of 0.5mol / L L of diethylaluminum chloride solution, aged at 5°C for 13 minutes; then added 600ml of triisobutylaluminum solution with a concentration of 0.75mol / L, and continued to age at 5°C for 48h to obtain a homogeneous catalyst C2. The molar ratio of each component in C2 is neodymium neodecanoate: triisobutylaluminum: diethylaluminum monochloride: isoprene: neodecanoic acid=1:19.6:3.5:58:0.76.

[0078] (2) Butadiene-isoprene copolymerization. Under nitrogen protection, 2000g hexane, 200g butadiene, 50g isoprene and 120ml catalyst C2 were sequentially added to the polymerization kettle at -1...

Embodiment 3

[0081] This example is used to illustrate the preparation method of the butadiene-isoprene copolymer rubber of the present invention.

[0082] (1) Catalyst preparation. Add 4000ml of hexane, 50ml of concentration of 0.50mol / L neodymium neodecanoate solution, 70g of butadiene and 1.8g of neodecanoic acid to the dry aging kettle under nitrogen protection; then add 150ml of concentration of 0.5mol / L L of diethylaluminum chloride solution, aged at 10°C for 15 minutes; then added 270ml of triisobutylaluminum solution with a concentration of 1.14mol / L, and aged at 10°C for 30h to obtain a homogeneous catalyst C3. The molar ratio of each component in C3 is neodecanoic acid neodymium: triisobutylaluminum: diethylaluminum monochloride: butadiene: neodecanoic acid = 1: 12.3: 3.0: 52: 0.42.

[0083] (2) Butadiene-isoprene copolymerization. Under the protection of nitrogen, add 2000g hexane, 200g butadiene, 55g isoprene and 100ml catalyst C3 to the polymerization kettle at 20°C, in whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com