Intra-system temperature-controlled algae liquid external circulating microalgae photobioreactor

A photobioreactor, external circulation technology, applied in photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve water waste, carbon dioxide waste, culture intrusion. to avoid carbon dioxide waste, improve efficiency and quality, and reduce adherence and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

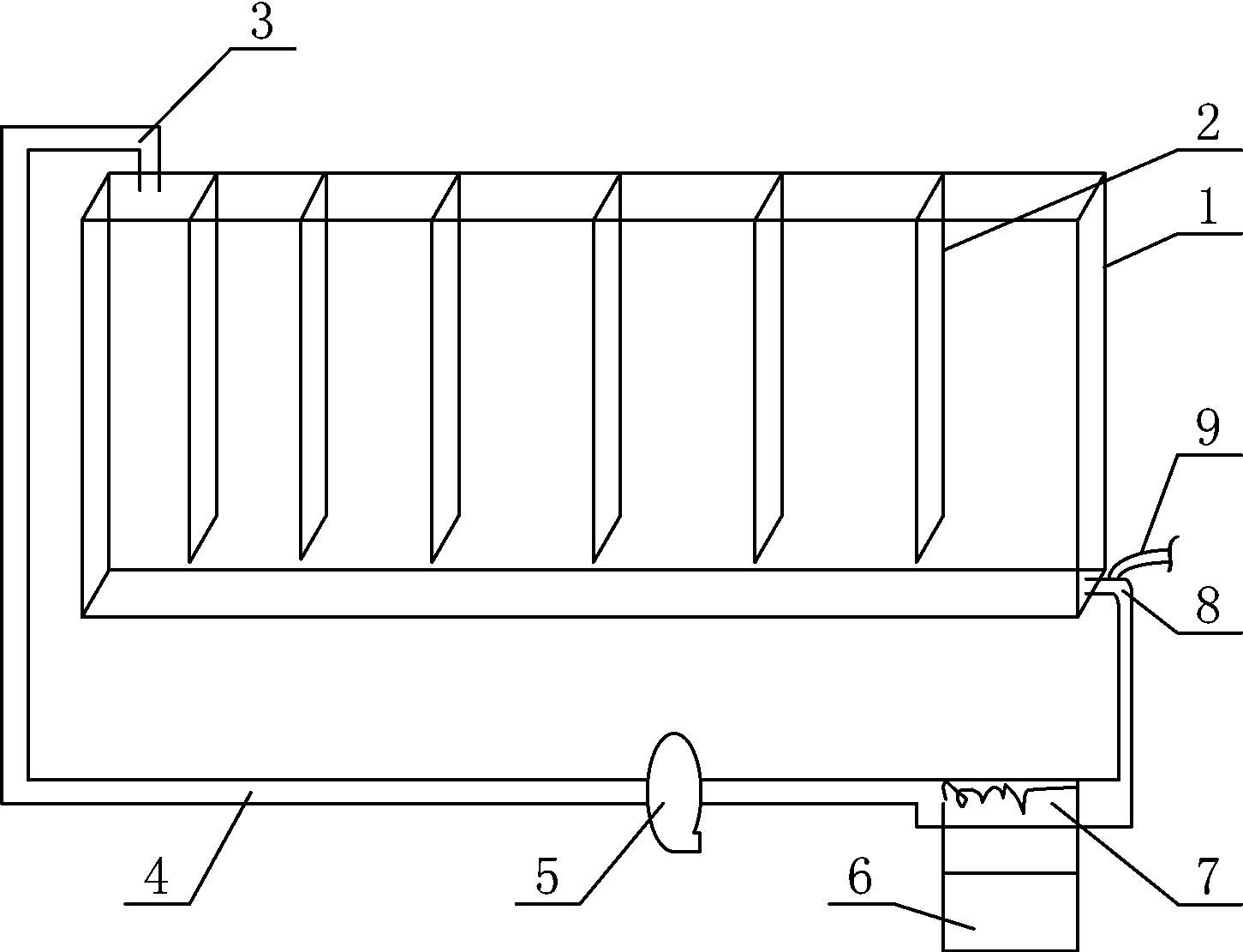

[0020] Such as figure 1 , the embodiment of the present invention comprises the cuboid shape cylinder body 1 that is made of transparent material and is closed on six sides, and the length of cylinder body 1 is much larger than its height and width, and the height of cylinder body 1 of this embodiment is 70-100cm, and length is 500-3000cm, Thickness 1-20cm.

[0021] In the cylinder body 1, a certain distance (60-100 cm in this embodiment) is fixed at every interval along the length direction (60-100 cm in this embodiment), and a vertical partition 2 that increases turbulence and strengthens the cylinder body is fixed. The distance between the end surfaces is 0-30cm (in this embodiment, the upper end of the vertical partition 2 is flush with the upper end surface of the reactor cylinder), and there is a gap of 2-10cm between the lower end of the partiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com