Automatic optimization control system and automatic optimization method for constant sliding pressure of steam turbine unit

A steam turbine unit, automatic optimization technology, applied in general control system, control/regulation system, adaptive control and other directions, can solve problems such as large throttling loss, large change in unit load, large adjustment deviation, etc., to reduce coal consumption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

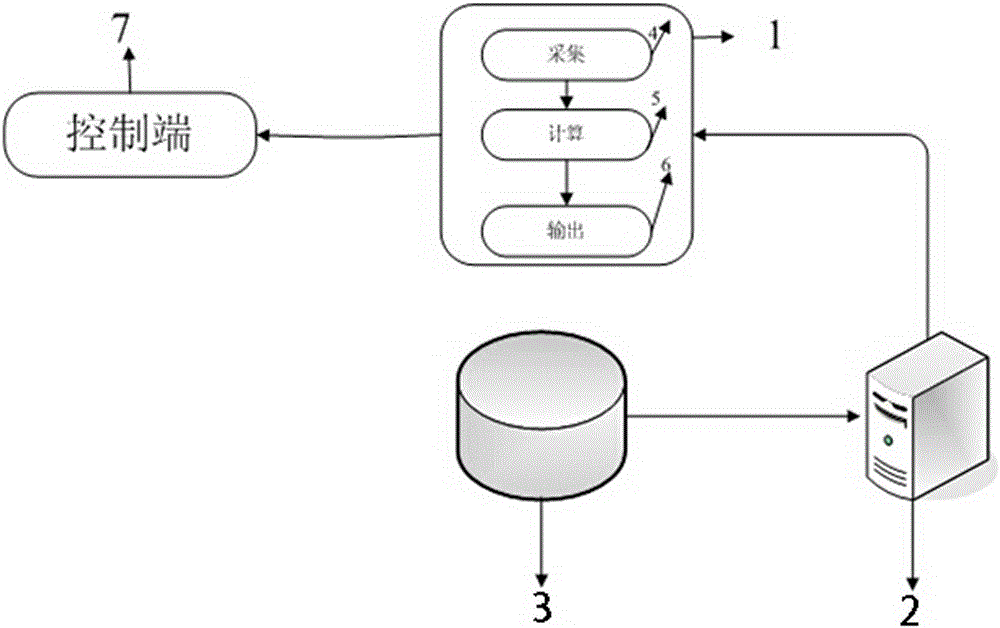

[0027] A preferred embodiment of the constant sliding pressure automatic optimization control system and its automatic optimization method of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, the constant sliding pressure automatic optimization control system of the steam turbine unit includes: a unit PI server 2, a unit DCS control engineer station 3 for uploading data to be processed to the unit PI server 2; for collecting from the unit PI server 2 Relevant parameter data and carry out the data acquisition calculation output platform 1 of processing; Wherein, on the one hand unit PI server 2 is connected with unit DCS control engineer station 3 through local area network or Ethernet; On the other hand, unit PI server 2 is connected with described The data acquisition computing output platform 1 is connected. The data collection and calculation output platform 1 is connected with the unit coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com