Bus conductor assembly tool

A technology for assembling tooling and conductors, applied in cable laying equipment and other directions, can solve the problems of reducing the size of the tooling, easy to deviate, and inconvenient to take out the tooling, and achieve the effect of shortening installation time, reducing labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

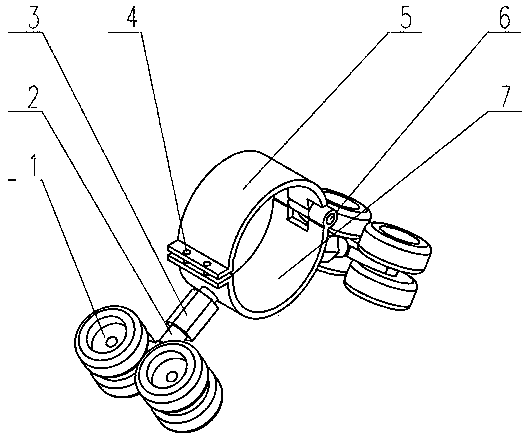

[0021] See attached figure 1 , this embodiment includes a supporting plate 7 and a pinch plate 5, one end of the pinching plate 5 and the supporting plate 7 is hinged by a pin 6, and the other end is fixedly connected, and the supporting plate 7 and the pinching plate 5 are closed to form a closure that can accommodate the conductive rod. hole (i.e. clamping hole); the two sides of the supporting plate 7 are respectively provided with an adjusting screw, the supporting plate 7 is connected with the set wheel supporting frame through the adjusting screw 3, and the other end of the wheel supporting frame 2 is provided with two A wheel 1 that can move in the bus barrel, the wheel 1 is arranged along the axial direction of the bus barrel, and the height of the supporting plate 7 is adjusted by the adjustment screw 3. When not in use, ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com