Method of recovering rhenium by fluidized-roasting rhenium-containing minerals

A fluidized roasting and mineral technology, applied in the field of rhenium-containing minerals fluidized roasting recovery rhenium, can solve the inevitable automatic floating, excessive roasting cycle, affecting the recovery rate of rhenium, etc., to improve the unit production capacity, Effects of increasing the sublimation rate and reducing the amount of roasting dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

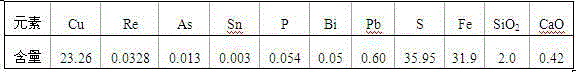

Embodiment 1

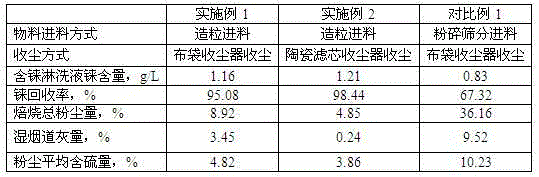

[0038] Raw materials: rhenium-containing copper sulfide concentrate, copper 23.26%, rhenium 328g / t, multi-element chemical analysis results are shown in Table 1:

[0039] Table 1 Results of multi-element chemical analysis of copper sulfide concentrate / %

[0040]

[0041] equipment:

[0042] Fluidized fluidized furnace: with a vertical cylindrical refractory chamber, the fluidized layer area is 3.08m2 2 , the lower part of the furnace bottom is provided with an air distribution plate with holes, the air distribution plate is composed of a number of detachable steel nozzles, and refractory clay is filled between the nozzles to make the air flow through here and spray upwards evenly; the middle part of the furnace body There is a feeding port; there is a discharge hole at a height of 1300mm upward from the bottom of the furnace; there is a furnace gas outlet on the top of the furnace chamber;

[0043] Automatic feeding device: It consists of a circular hopper and a dish-shap...

Embodiment 2

[0055] Raw material: with embodiment 1.

[0056] equipment:

[0057] Fluidized furnace, automatic feeding device and granulator: with embodiment 1;

[0058] Dust removal system: communicated with the furnace gas outlet on the top of the furnace chamber through the flue, with 1 set of cyclone dust collectors and 3 sets of ceramic filter dust collectors. The ceramic filter dust collector is equipped with a pulse blowback system to clean the ceramic filter elements. , the electrical control mode of the ceramic filter element dust collector is the same as the electrical control mode of the bag filter in Example 1, using PLC control and corresponding solenoid valves to control dust filtration and blowback; the specification of the ceramic filter element is Φ100×90×2500, and its The aperture is 5μm; the dust removal system is connected to the spray system;

[0059] Processing condition: with embodiment 1.

[0060] Implementation process:

[0061] The hot air first enters the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com