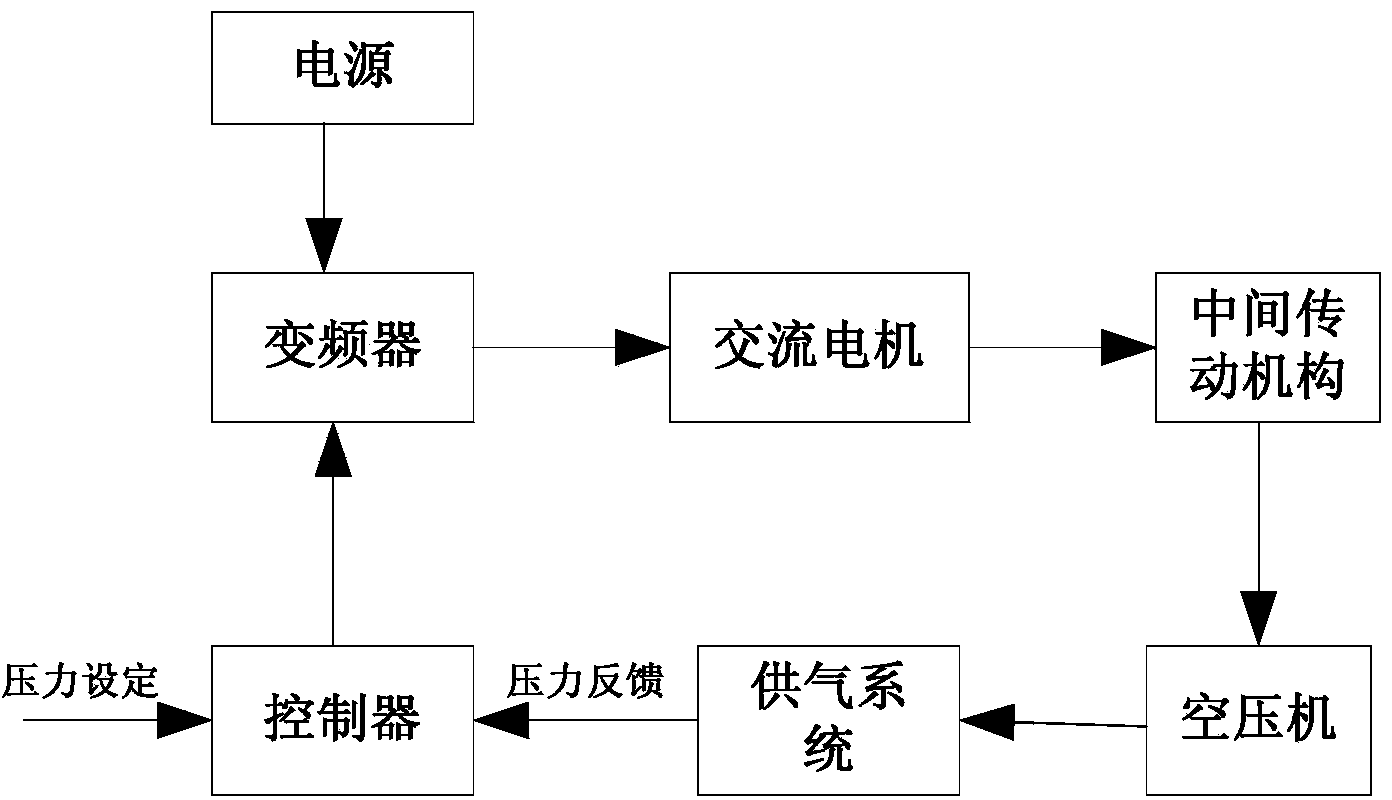

Frequency converter special for air compressor and air compressor variable-frequency drive control system

A variable frequency drive and control system technology, applied in the control system, machine/engine, AC motor control, etc., can solve the problem of incompatibility of the frequency converter, and achieve the effect of reducing wiring, reducing product volume, and saving air compressor controllers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

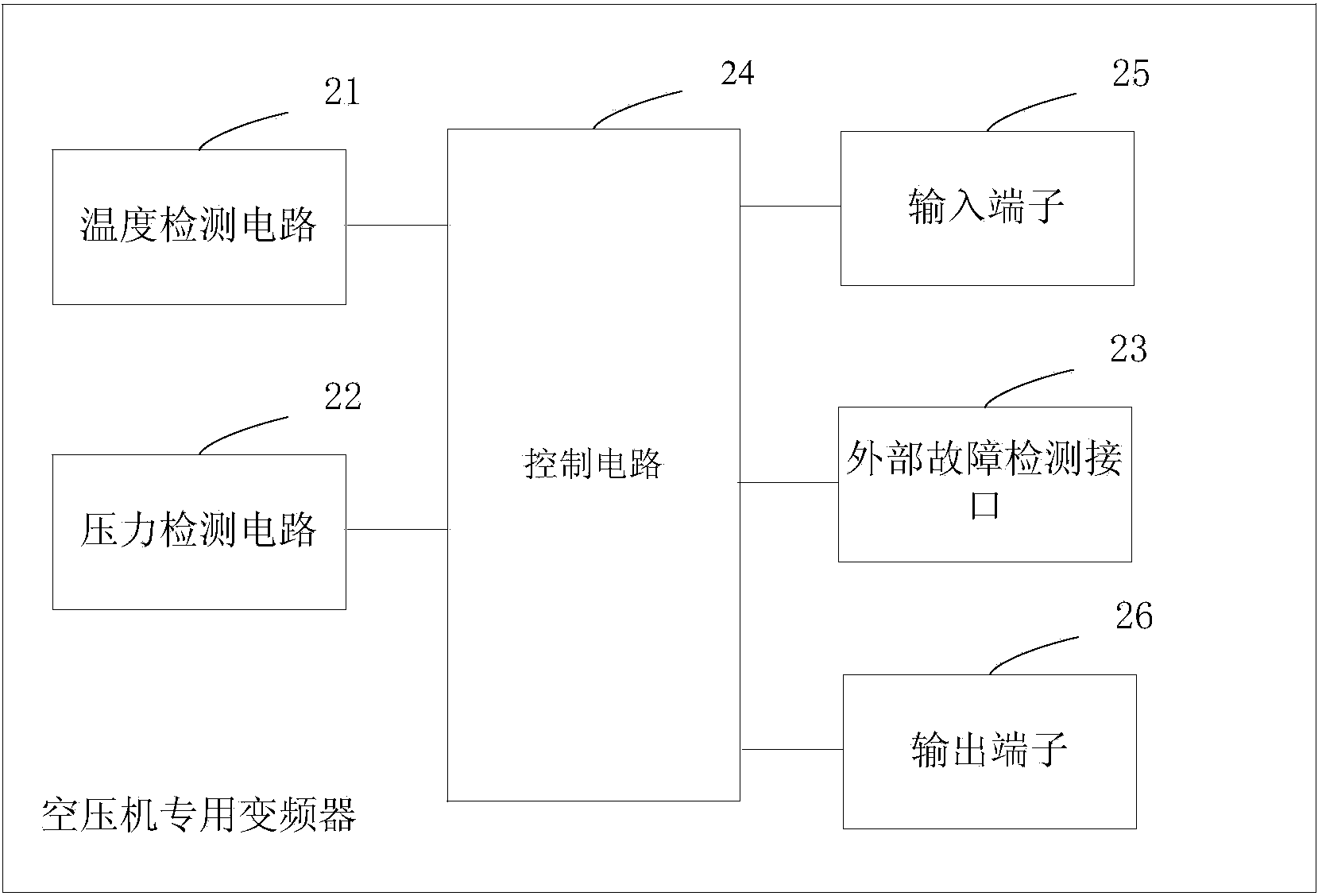

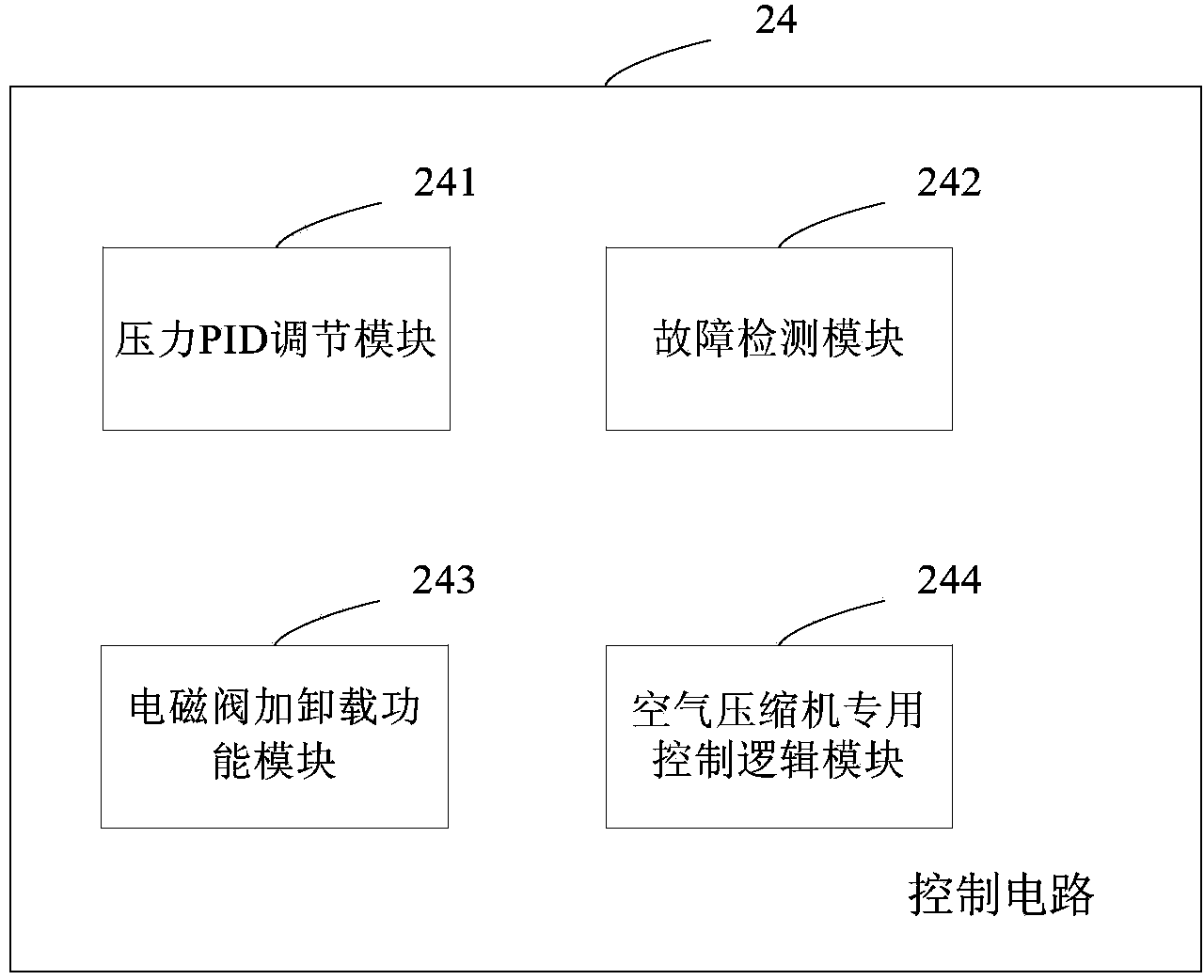

[0053] See figure 2, which shows a schematic structural diagram of the special frequency converter for air compressors provided by the present application. The special frequency converters for air compressors include: temperature detection circuit 21, pressure detection circuit 22, external fault detection interface 23, control circuit 24, input terminal 25 and output terminal 26. in:

[0054] The temperature detection circuit 21 is used to detect the temperature of the head of the air compressor.

[0055] In this embodiment, the temperature detection circuit 21 is connected to the temperature sensor PT100 installed on the head of the air compressor, and the PT100 converts the temperature signal into a current signal through a temperature transmitter, and then inputs it through the analog quantity of the air compressor dedicated frequency converter The terminal is sent to the temperature detection circuit 21, and the temperature detection circuit 21 detects and obtains a te...

Embodiment 2

[0088] In this embodiment, an air compressor variable frequency drive control system is shown, please refer to Figure 4 , which shows a schematic structural diagram of an air compressor variable frequency drive control system provided in the present application. The air compressor variable frequency drive control system at least includes: an air compressor dedicated frequency converter 41 and a fan driver 42 .

[0089] The frequency converter 41 dedicated to the air compressor is used to drive and control the host of the air compressor.

[0090] For the specific structure and related functions of the frequency converter 41 dedicated to air compressors, please refer to the frequency converter dedicated to air compressors shown in Embodiment 1, and details will not be repeated here.

[0091] The fan driver 42 is used to drive the fan of the air compressor.

[0092] See Figure 5 , which shows another schematic structural diagram of the air compressor variable frequency drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com