Electromagnetism dynamic loading device

A dynamic loading, electromagnetic technology, applied in vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problem of inability to apply or offset dynamic axial force balance, achieve structural optimization, simple and easy manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

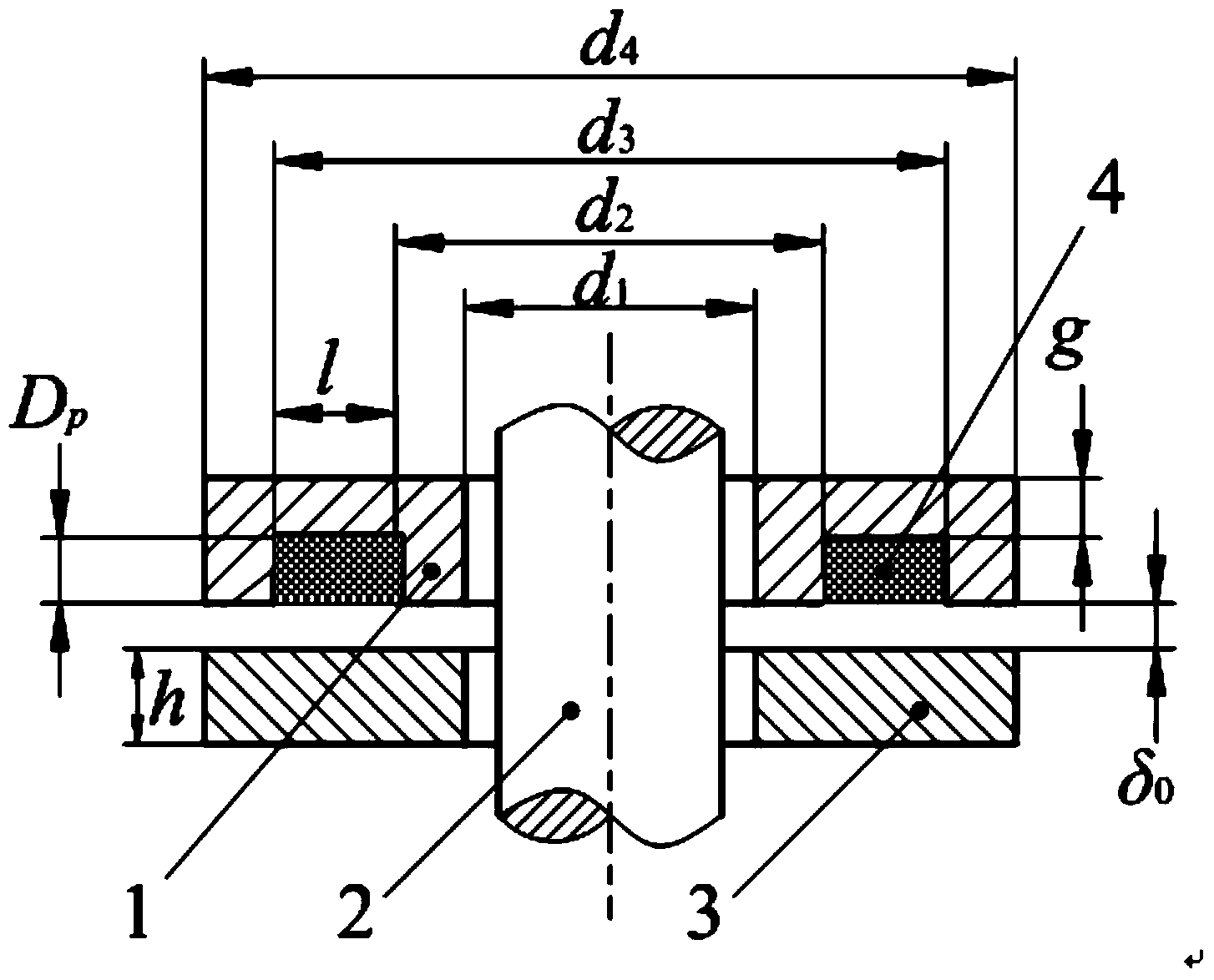

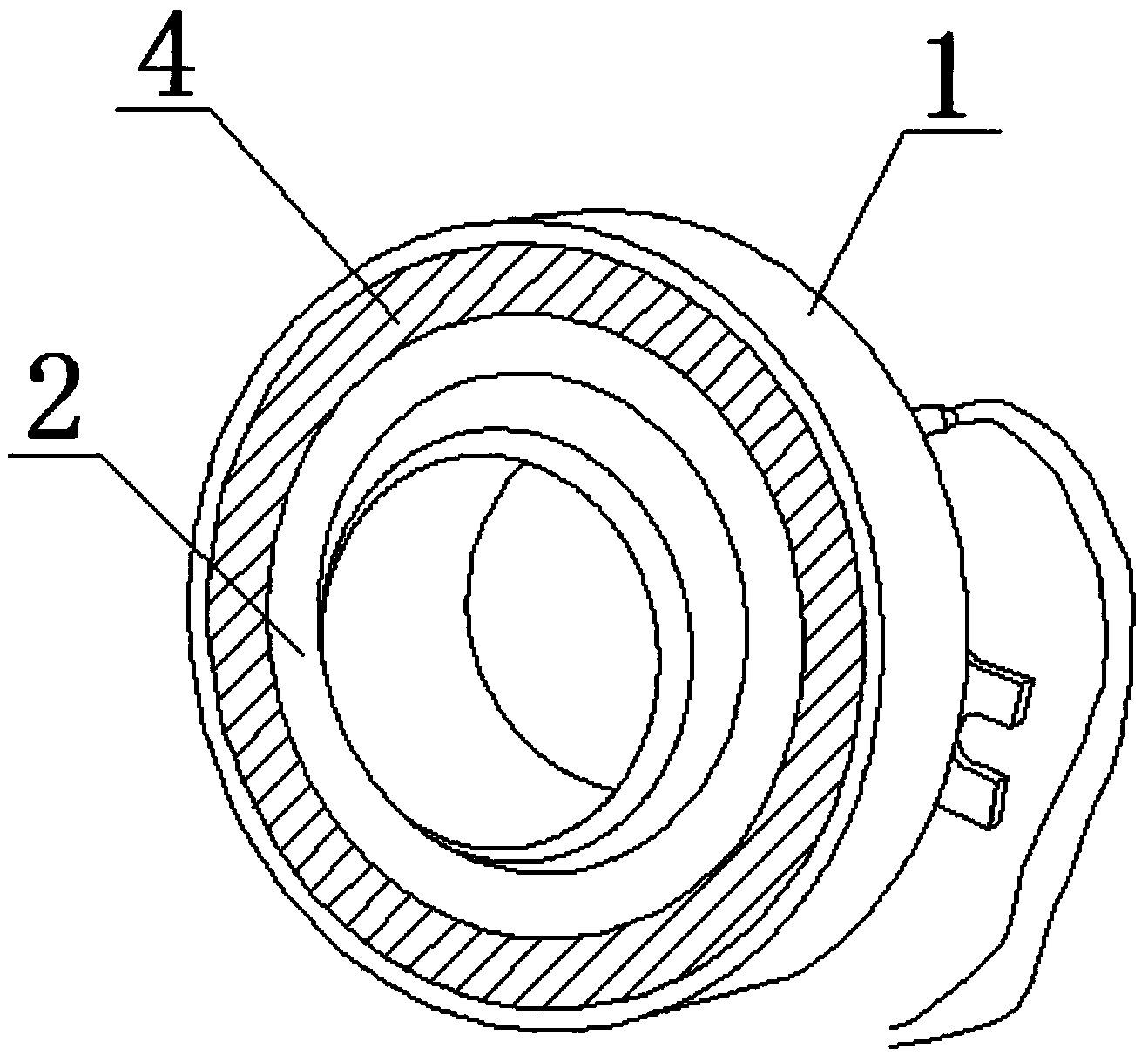

[0028] An electromagnetic dynamic loading device, comprising an annular electromagnetic end cover 1 and a flange 3 connected to the electromagnetic end cover 1, the electromagnetic end cover 1 is provided with an annular coil slot, and the annular coil slot is provided with There is a conductive coil 4 that can pass through the current; the inner side of the electromagnetic end cover 1 is also fixedly connected with an electromagnet core 2, and the electromagnetic core 2 is arranged on the inner side of the conductive coil 4; the electromagnetic core 2 is cylindrical Structure; the conductive coil 4 is placed in the annular coil slot, and is filled with insulating glue.

[0029] The above-mentioned electromagnetic dynamic loading device also includes a variable current regulator, the port of the conductive coil 4 is electrically connected to the output end of the variable current regulator; the current adjustment range of the variable current regulator is 0-10A; There is a gap...

Embodiment 2

[0089] According to the calculation results of the above-mentioned embodiment 1 and the actual installation requirements, the electromagnetic end cover is designed in detail, and the material is 45 steel. The flange matched with the electromagnetic end cover 1 is made of 45 steel.

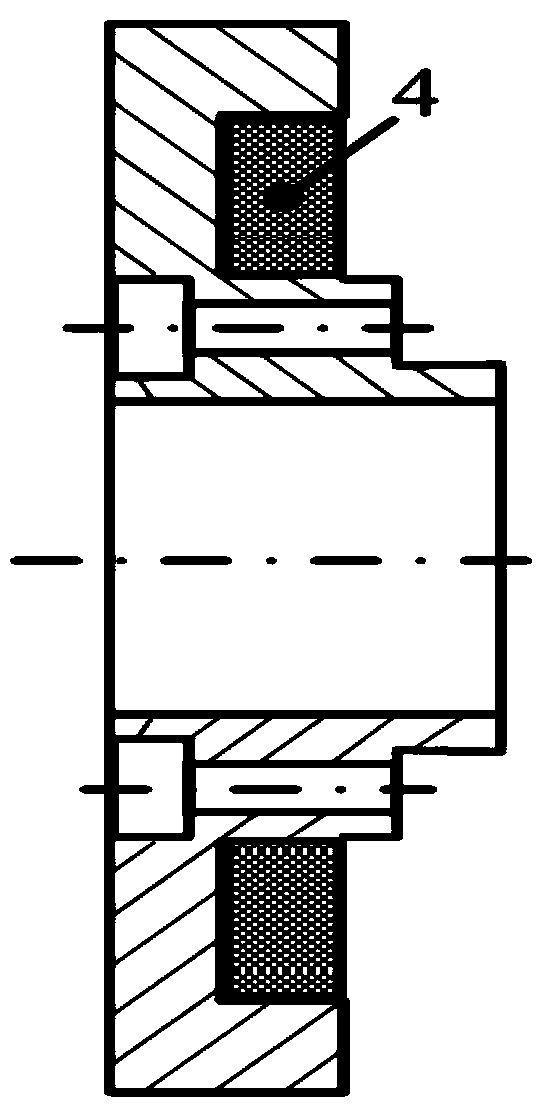

[0090] The structure diagram of electromagnetic end cover 1 is shown in figure 2 After the processing is completed, wind the electromagnetic coil in the groove, and then fix it with latex paint. The completed electromagnetic end cover 1 is as image 3 shown.

[0091] 1) Selection of adjustable current regulator

[0092] The electromagnet needs to provide a stable DC power supply, calculated from the above

[0093] I 0 =5.6A,P 0 =I 0 2 R t =27W, U 0 =P 0 / I 0 =4.8V, where R t = 0.86Ω.

[0094] Generally, the maximum current

[0095] I max =1.12I 0 =1.12×5.6=6.3A

[0096] The maximum output power is 35W and the maximum voltage is 5.6V.

[0097] According to the above calculation re...

Embodiment 3

[0111] In the above-mentioned embodiment, the current size loaded on the conductive coil 4 is manually controlled and adjusted by the variable current regulator, so as to realize the purpose of adjusting the electromagnetic field force; the difference from the above-mentioned embodiment is that the adjustment of the current can not only be adjusted by It can be adjusted manually, and it can also be connected with a variable current regulator through a controller, industrial computer or control platform to realize automatic adjustment of the current.

[0112] The axial electromagnetic force provided by the electromagnetic dynamic loading device is limited by the current variation range and temperature rise of the variable current regulator, and a cooling device can be added if necessary.

[0113] The operating environment temperature of the electromagnetic dynamic loading device system is from room temperature to 40°C, and the allowable temperature rise is less than 60°C.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com