Cooling-heating-integrated double-capillary-tube-layer phase-change energy storage floor terminal device and application system

A phase-change energy storage and terminal device technology, which is applied in new air conditioners, building heating, structural design of new energy storage floors, integrated terminal devices and application systems. Achieve the effect of solving the peak-valley difference of power, reducing building energy consumption, and saving power operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

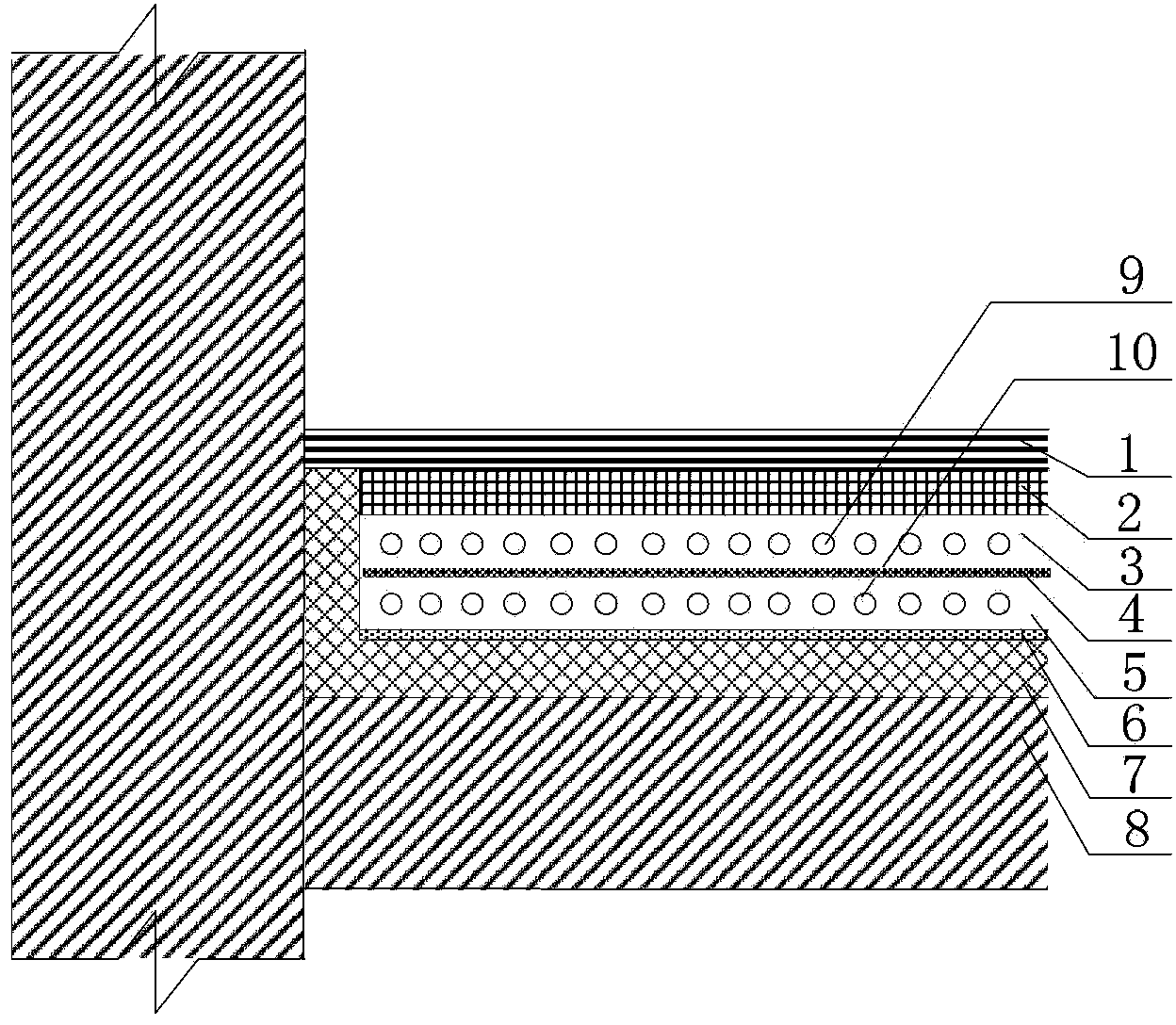

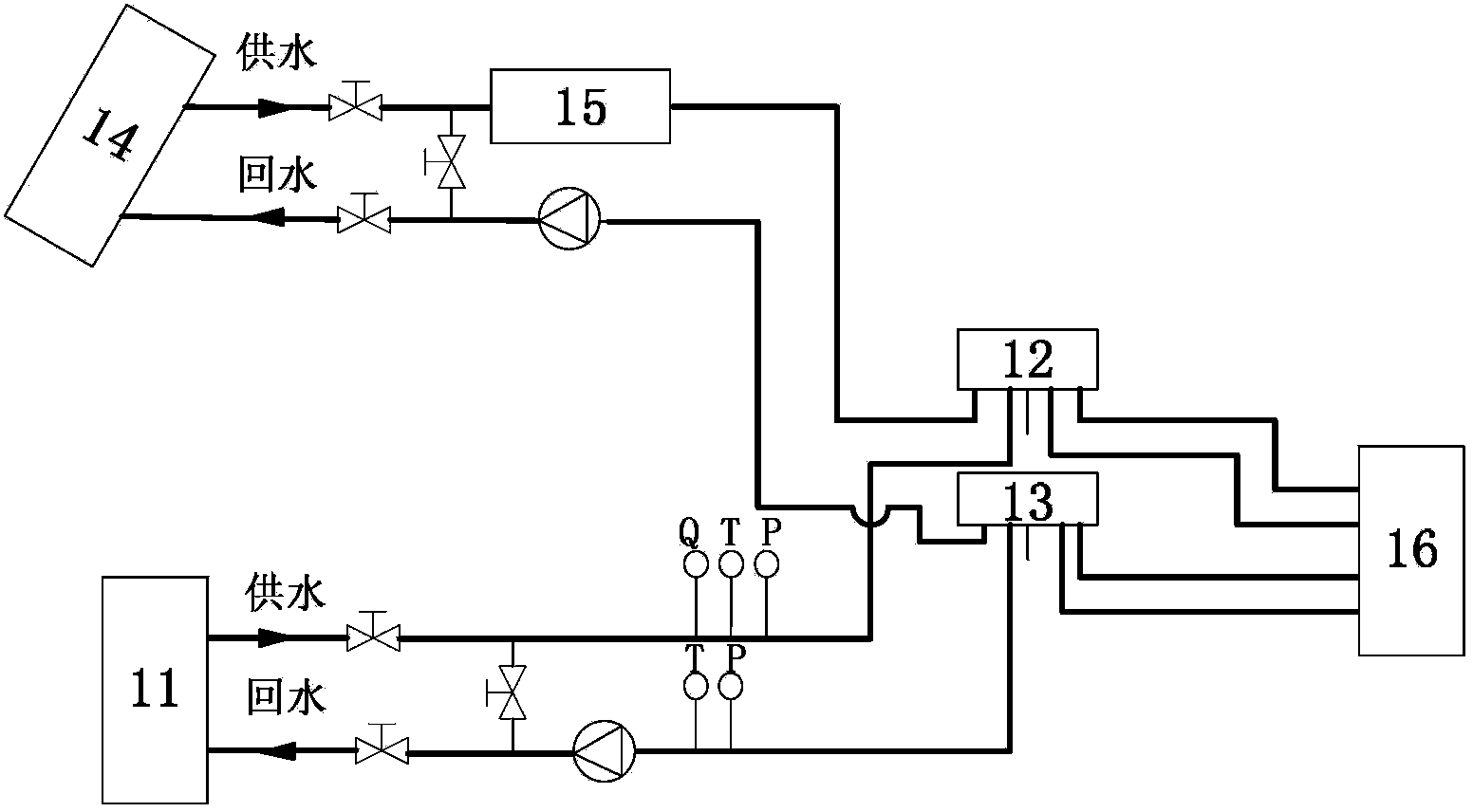

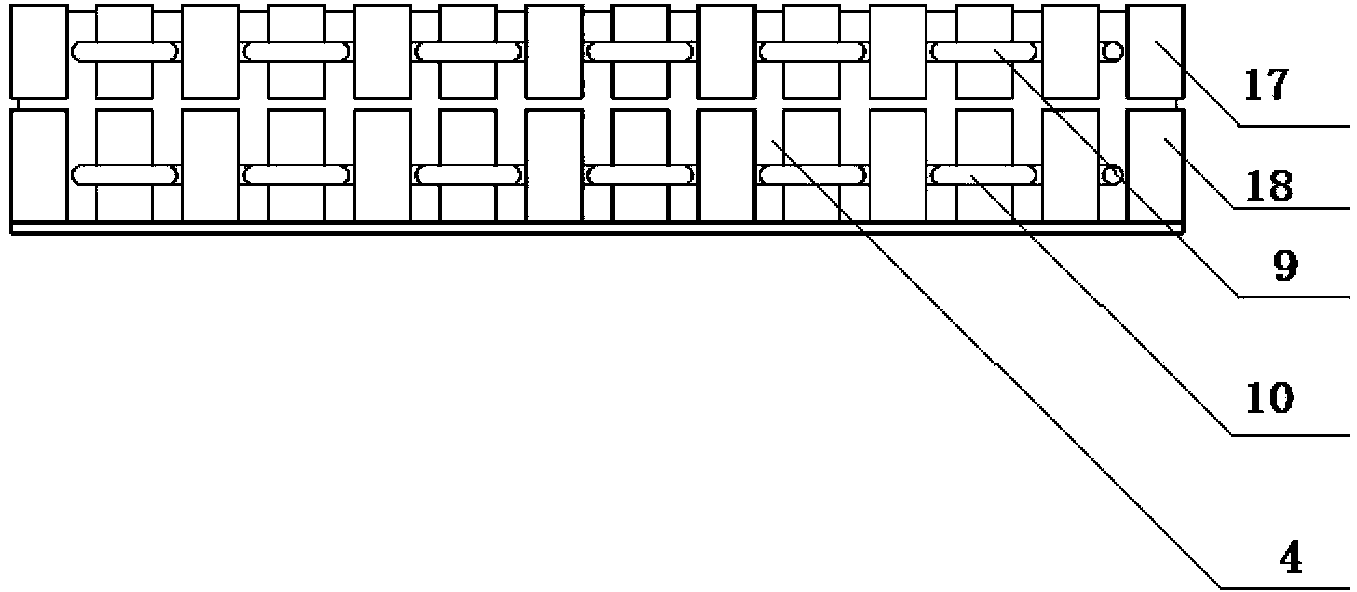

[0032] The cold and hot integrated double-layer capillary phase change energy storage floor terminal device and application system of the present invention, such as figure 1 As shown, the flow chart of the system is as follows figure 2 Shown, describe in detail below in conjunction with accompanying drawing.

[0033] See Figure 1 to Figure 5 Each layer of the floor of the device from top to bottom is the floor surface layer 1, the concrete layer 2, the thermal storage phase change material layer 3, the cement mortar leveling layer 4, the cold storage phase change material layer 5, the reflective film 6, the thermal insulation layer 7 and the Floor structure layer 8. The phase change material is packaged in a strip-shaped metal, and a layer of cement mortar leveling layer 4 is laid between the thermal storage phase change material layer 3 and the cold storage phase change material layer 5, which not only solves the problem of state change during the phase change process, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com