Energy-saving type automatic control multi-room rice flour dryer

A dryer, energy-saving technology, applied in dryers, drying, food preparation and other directions, can solve the problems of wasting energy, dead ends of rice noodle drying, separate control, etc., to avoid waste of resources and improve utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific embodiment:

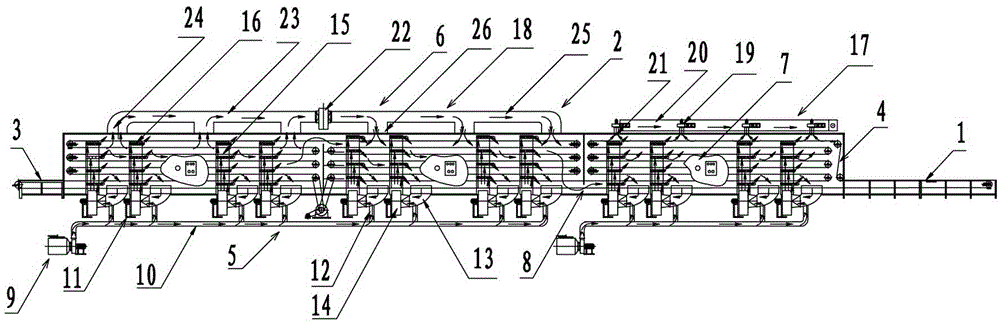

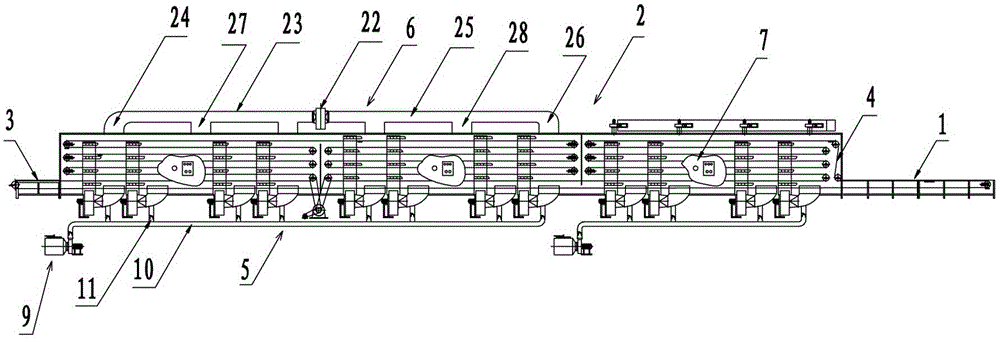

[0046] See attached figure 1 and 2 As shown, an energy-saving automatic control multi-chamber rice noodle dryer described in this embodiment. The dryer includes a feed rack 1 at the right end for rice flour to enter the dryer body 2, a rice flour dryer body 2 at the middle position, a discharge rack 3 for rice flour output, and a rice flour conveying system 4 , a hot air circulation system 5 for providing heat to the dryer body 2, a dehumidification circulation system 6, and an automatic control system 7 for controlling the temperature and humidity of the air in the unit room, wherein the dryer body 2 includes at least three or more The drying chamber units are connected successively.

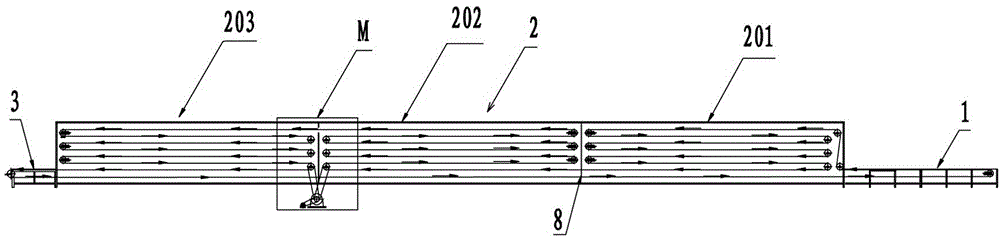

[0047] See attached figure 1 and 3 Shown, rice noodle conveying system 4 among the present invention adopts chain conveying structure. The rice noodle conveying system 4 runs through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com