Oil-proof benzene-free PVC gloves and preparation technology thereof

A preparation process, a technology of PVC resin powder, applied in the field of PVC gloves, can solve the problems of accelerating the aging of natural rubber gloves, natural rubber gloves are not very strong in oil resistance and heat resistance, etc., and achieve the effect of cheap price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

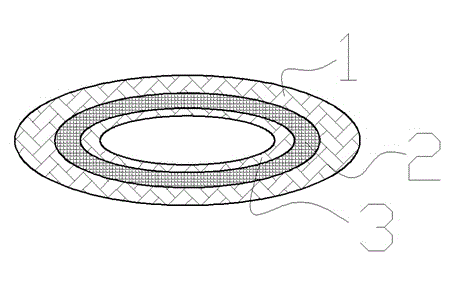

[0033] Such as figure 1 As shown, an embodiment of the present invention is oil-resistant and benzene-free PVC gloves, and the oil-resistant and benzene-free PVC gloves include a plasticizer and a non-toxic grade PVC resin powder, and the weight ratio of the plasticizer to the non-toxic grade PVC resin powder is It is 83:100; Specifically, the plasticizer described in this embodiment is non-phthalic acid. A specific implementation is as figure 1 As shown, the oil-resistant and benzene-free PVC gloves in this embodiment include three layers: the outer layer 1 of the glove, the middle layer 2 of the glove, and the inner layer 3 of the glove. The inner layer 3 of the glove is completely wrapped and adhered to each other by the middle layer 2 of the glove. Layer 1 is completely wrapped and adhered to each other. A preferred embodiment is that the outer layer 1 of the glove is an oil-resistant medium-polymerization PVC resin, the middle layer 2 of the glove is PVC resin with a lo...

Embodiment 2

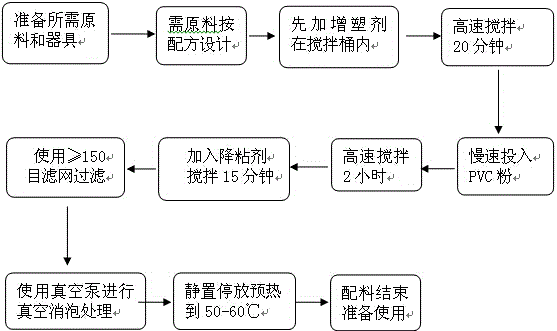

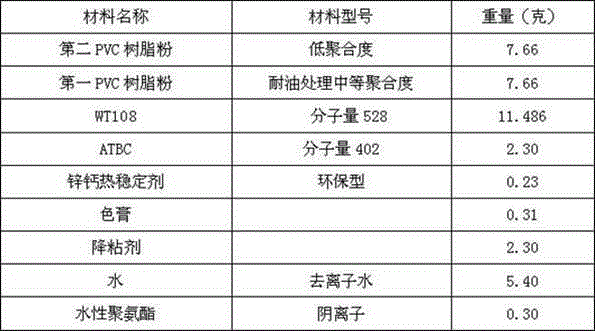

[0037] Such as figure 2 As shown, according to another embodiment of the present invention, this embodiment discloses a preparation process of oil-resistant and benzene-free PVC gloves as described above, wherein the specific materials used can refer to the following table:

[0038]

[0039] A preferred embodiment is that the preparation process includes the following steps:

[0040] First prepare the required raw materials and utensils, prepare according to the formula of the required raw materials in the above-mentioned embodiments, and carry out the production operation as follows after getting ready:

[0041] (1) Ingredients:

[0042] Mix the plasticizer and non-toxic PVC resin powder according to the weight ratio of 83:100. Among them, first add the plasticizer into the mixing tank, stir at high speed for 20 minutes, then slowly add PVC resin powder, and stir at high speed After 2 hours, add the viscosity reducer and stir for 15 minutes to form a paste-like slurry; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com