Liquor-brewing bottom boiler water filter and liquor-brewing bottom boiler water filtering method

A bottom pot water and filter technology, which is applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve the problems of increasing operating costs, reducing water passing efficiency, blocking filter holes, etc., and improving filtration efficiency. , the effect of increasing the filter area and increasing the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

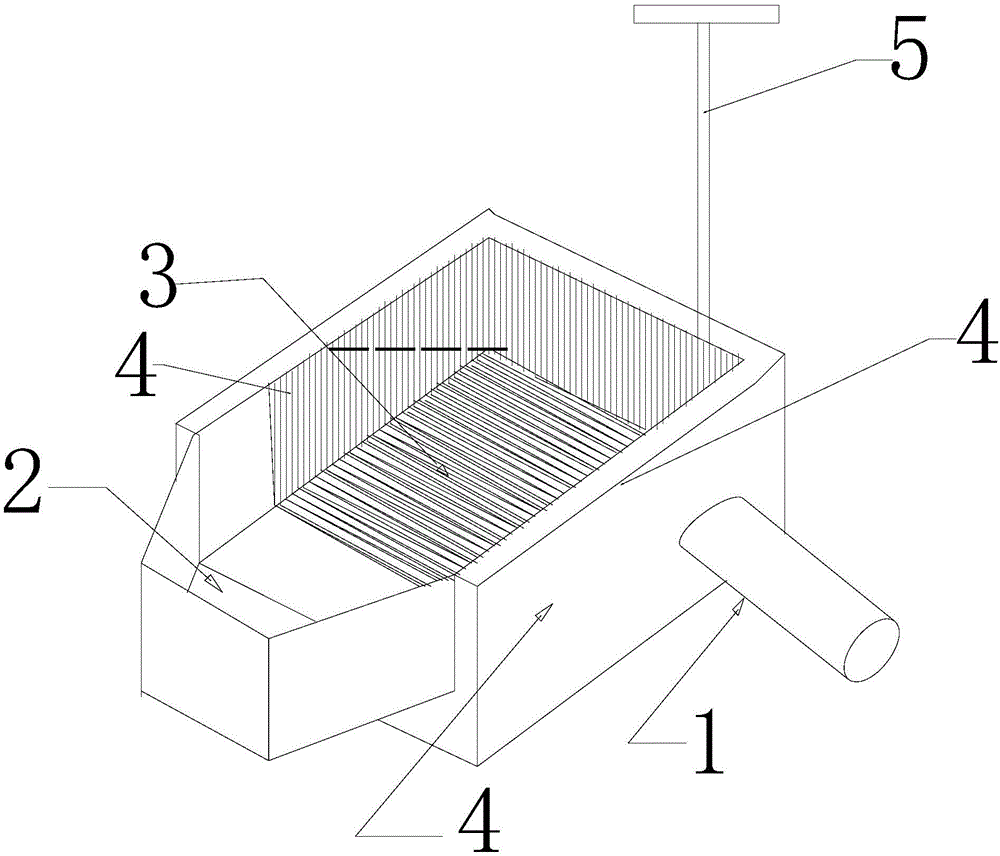

[0017] Such as figure 1 As shown, the wine brewing bottom pot water filter of the present invention comprises a water inlet pipe 1, a water collecting tank and a pedal 2, the water collecting tank is surrounded by a bottom plate 3 and three side plates 4 perpendicular to the bottom plate 3, and the pedal 2 is arranged on the collecting At the end of the water tank, the water inlet pipe 1 is arranged on the side plate 4 of the water collecting tank, the bottom plate 3 is a filter plate with sieve gaps, and the three side plates 4 are filter plates with sieve gaps. The high-temperature organic waste water produced by the bottom pot is put into the water collection tank of the brewing bottom pot water filter of the present invention through the pipeline of the multifunctional filter to separate the bad water. Composed of filter plates with sieve gaps, compared with the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com