Metal foam carrier CO2 adsorbent

A metal foam and adsorbent technology, applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems that affect the adsorption capacity, do not solve, do not consider the influence of heat, etc., to increase the adsorption capacity , high-efficiency adsorption, and overcome the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

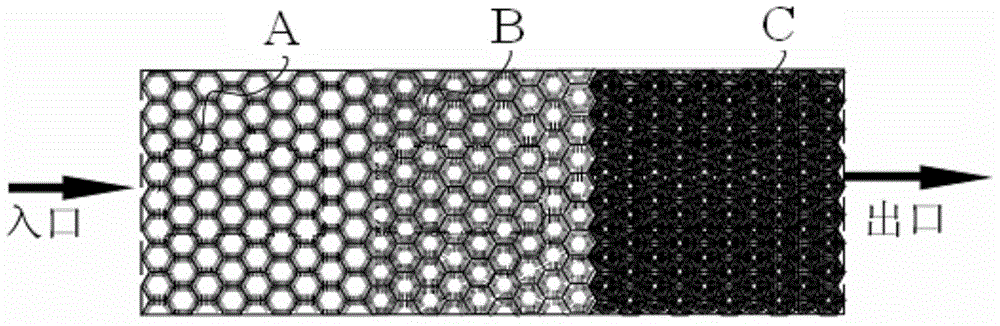

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

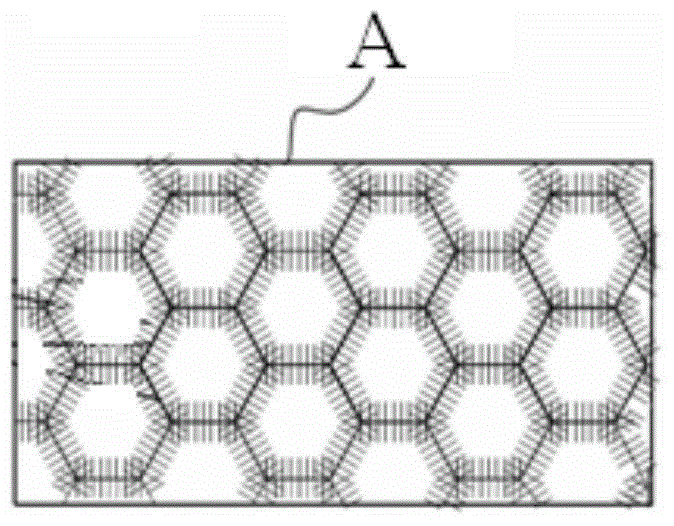

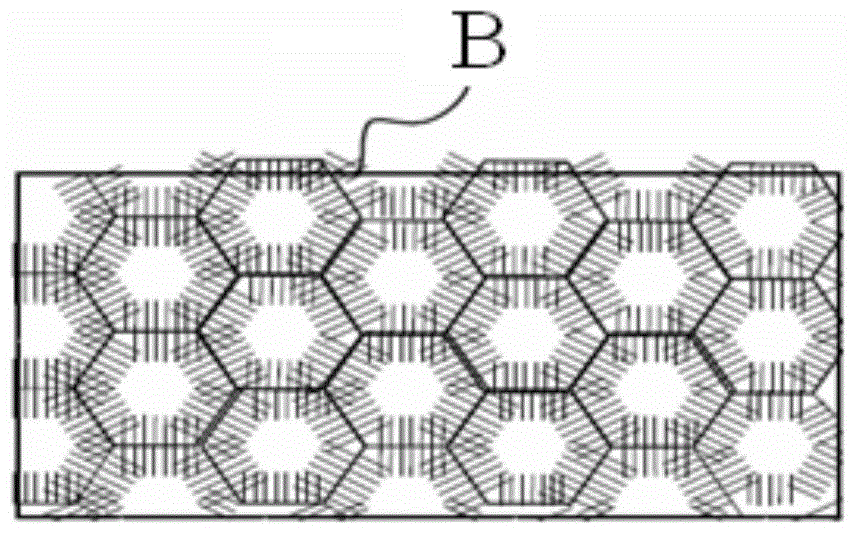

[0027] Such as figure 1 and Figure 5 As shown, the present invention includes a hollow continuous skeleton made of metal foam, and the pores of the metal foam are grown or filled with CO with a thermal conductivity of 0.06-0.12W / m·K. 2 adsorbent, and CO 2 The adsorbent is one or two of carbon nanorods, solid amine particles, and metal-organic framework compounds, and each pore of the metal foam is filled with a CO 2 The adsorbent, the metal organic framework compound is Cu-BTC, Ni-DOBDC or ZIF-8; the material of the metal foam is copper, nickel or iron.

[0028] (1) If figure 1 As shown, when CO 2 When the adsorbent is carbon nanorods, solid amine particles or metal-organic framework compounds, the present invention adopts the structure with the first technical solution, and the porosity of the metal foam is 0.90% to 0.97%, and the pore diameter is 0.7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com