Trepanning tool

A cutting tool and nesting technology, which is applied in drilling accessories, manufacturing tools, drilling/drilling equipment, etc., can solve the problem of the obstruction of the nesting tool screwing into the shaft to be processed, the poor dimensional accuracy of the inner hole, and the consumption of chips. It can achieve the effect of small cutting force, high precision of inner hole size and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

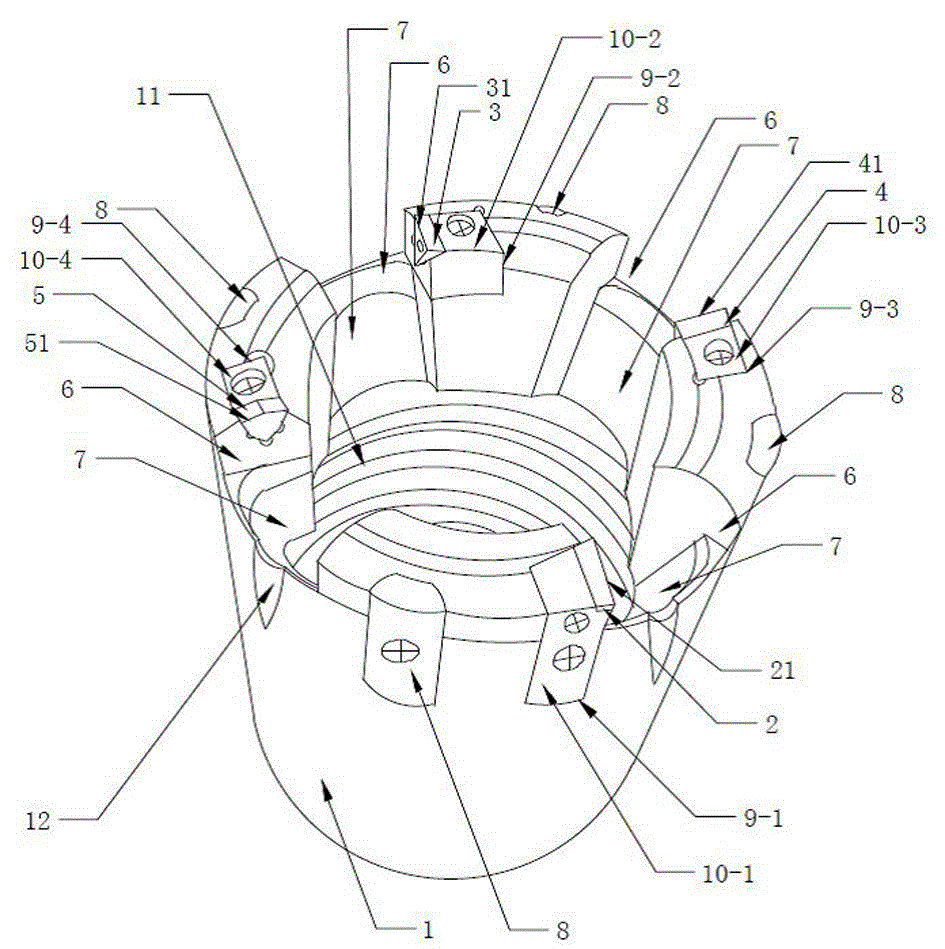

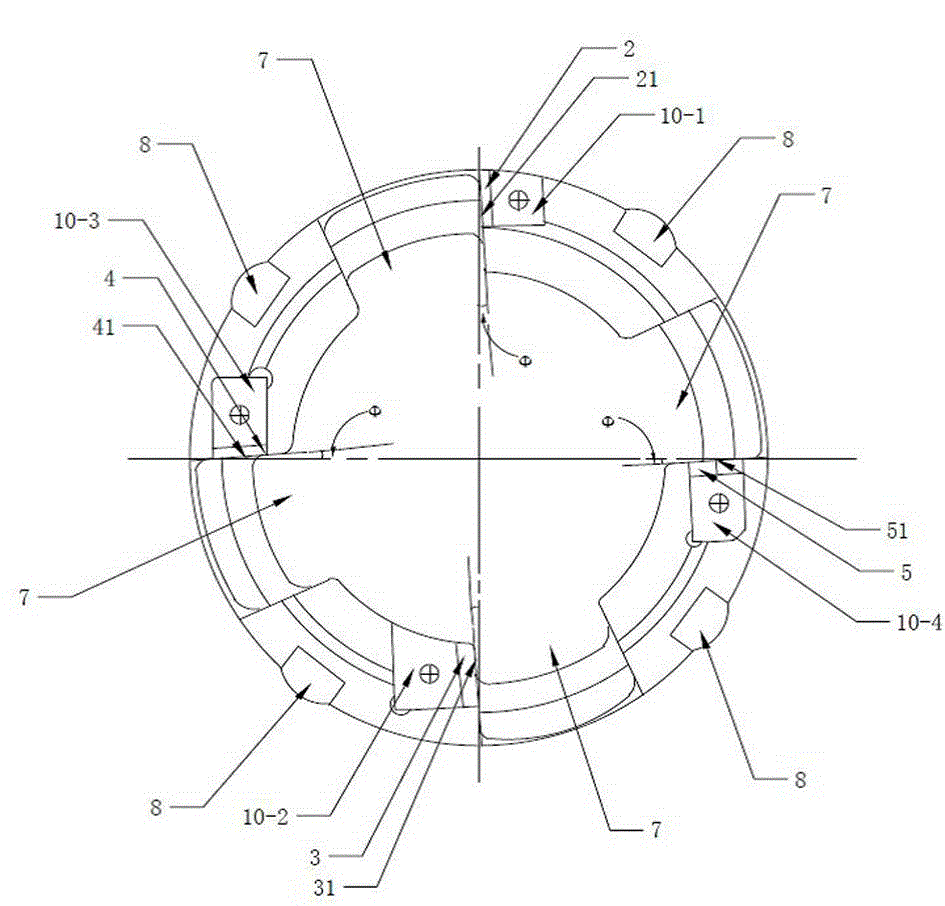

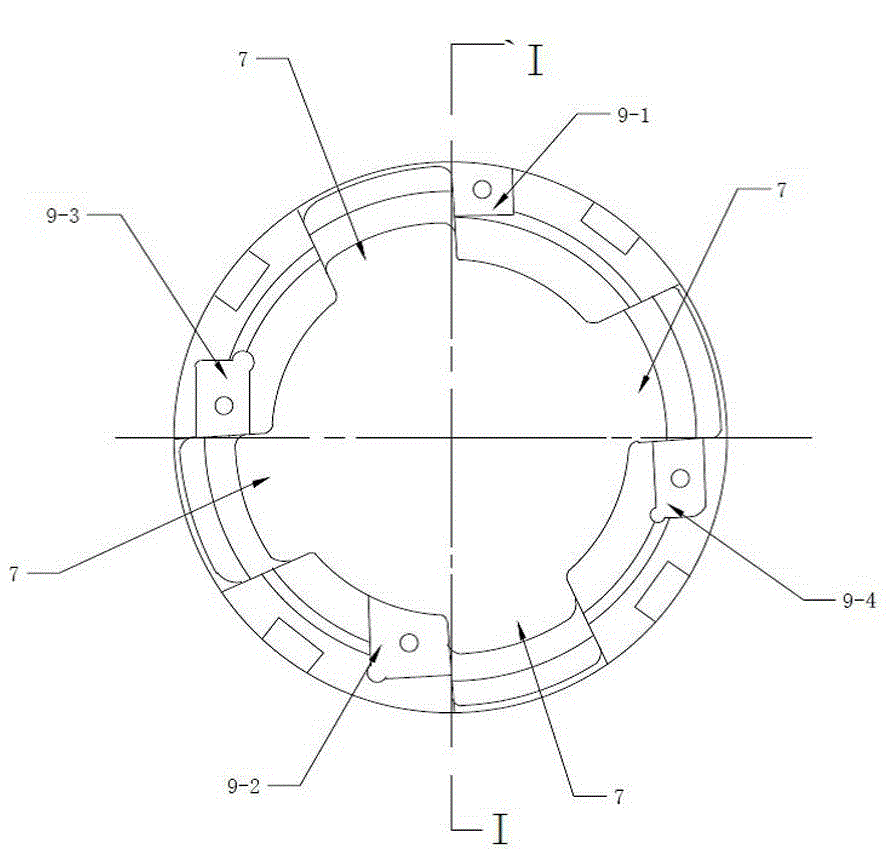

[0046] Such as Figure 1 to Figure 4 As shown, the present invention is a nesting cutter, comprising a cylindrical cutter body 1, one end face of the cutter body 1 is provided with several cutting knives, the other end of the cutter body 1 is provided with threads 11 for connection; In the different rings of the end face of the body 1, it includes an inner cutting knife 3 located in the inner ring, an outer cutting knife 2 located in the outer ring, and a middle cutting knife 4 located in the central ring. The main cutting edge 31 of the inner cutting knife 3 is from The inner wall of the cutter body 1 extends from the end surface of the cutter body 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com