A Method of Controlling Tailored Welding Deformation of Large Metal Tube Sheet

A welding deformation and tube sheet technology, applied in metal processing, metal processing equipment, furnace types, etc., can solve the problems of increased metal consumption and processing costs, reduced welding stress effect, and low deformation of the tube sheet, so as to save metal Consumption, reducing welding restraint, reducing the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The key equipment of the 50,000 tons / year maleic anhydride plant - the upper and lower tube sheets of the tubular fixed tube sheet reactor, the design requirements: diameter 6000mm, thickness 140mm, material: Q345R, tolerance of tube sheet flatness ≤ 3mm, each There are 26180 reaction tube holes on each tube plate.

[0040] The implementation steps are as follows:

[0041] (1) Tailor welding deformation control of tube plate blank:

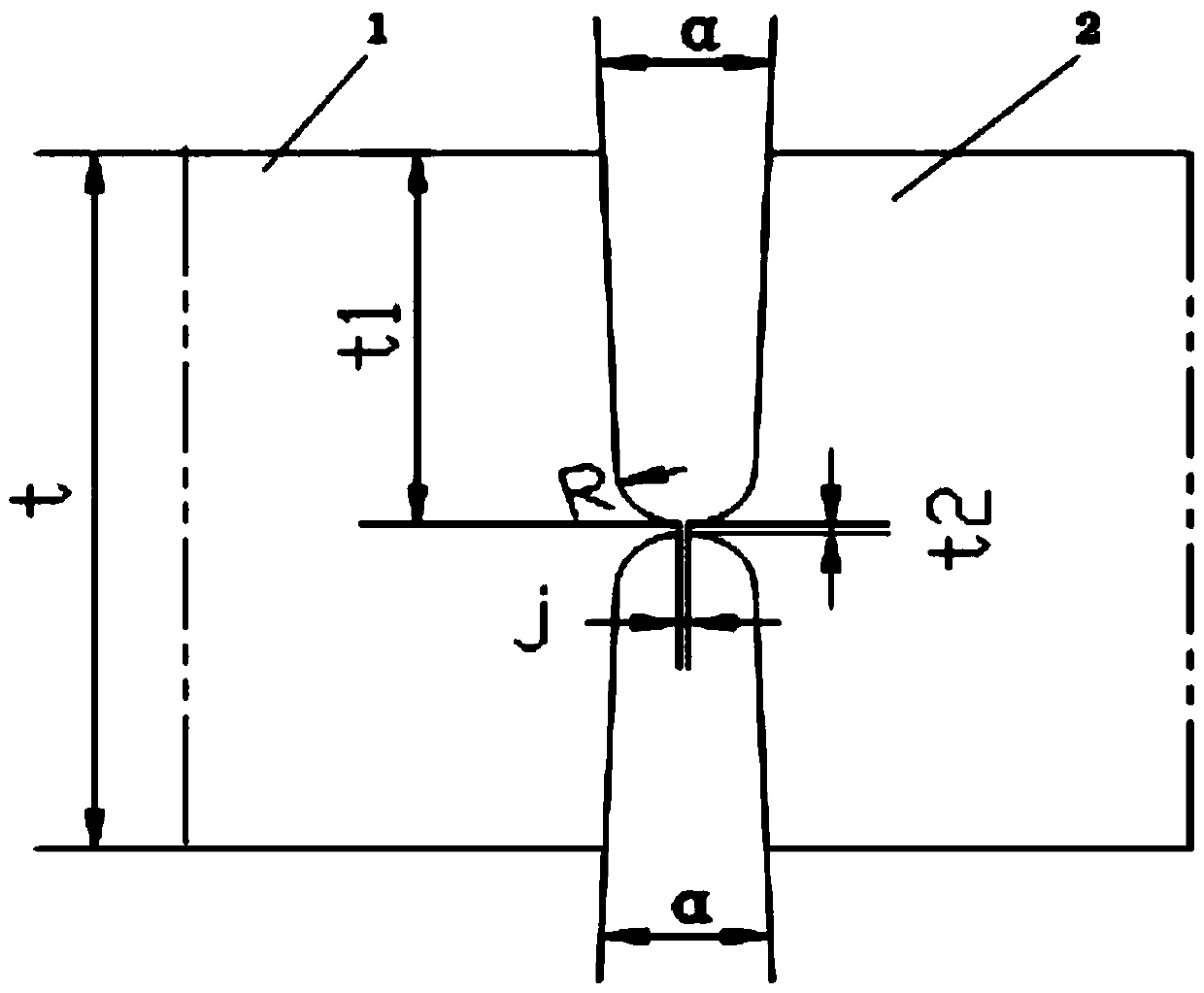

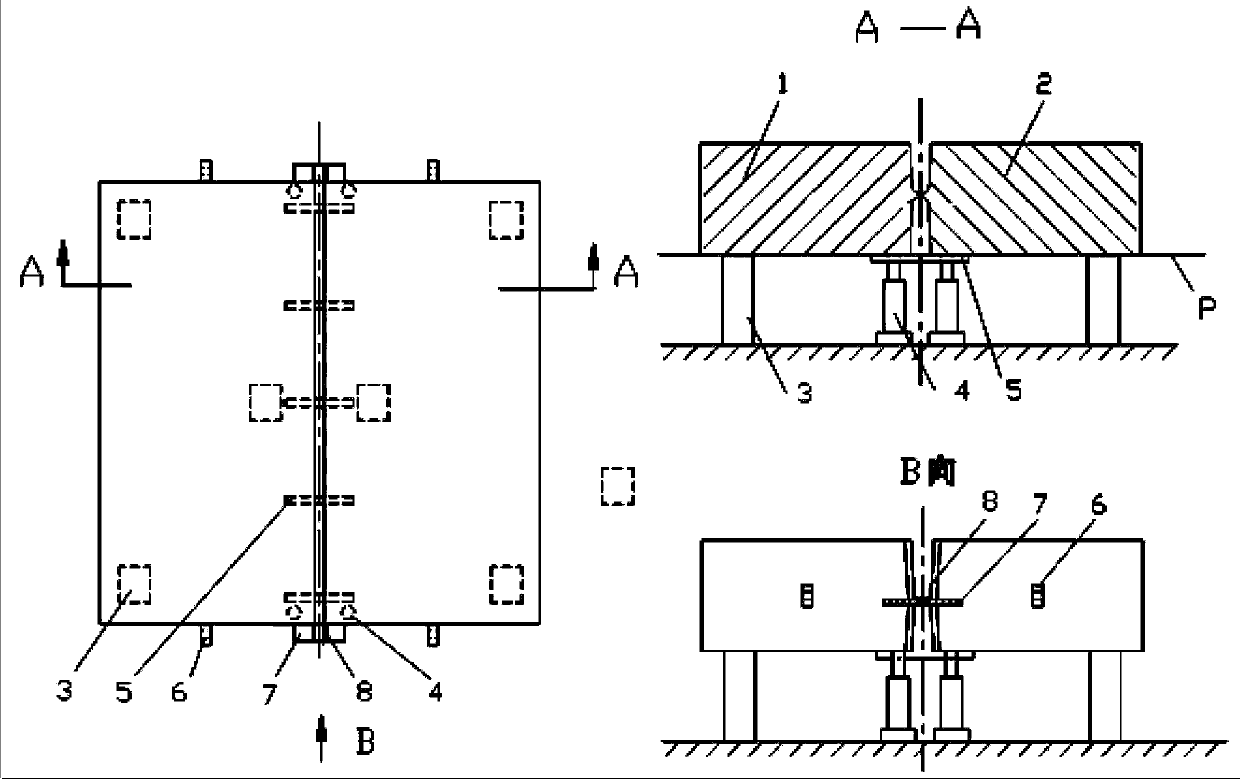

[0042] 1) In order to ensure the processing accuracy of the tube sheet, a 10mm margin for finishing is reserved for the tube sheet blank 11, so a positive deviation steel plate with a width of 3000mm+10-20mm is selected, the length is 6020mm, and the thickness t=150mm. Steel plate 1 and steel plate 2 made of Q345R (normalized) are tailor-welded into tube plate blanks;

[0043] 2) Steel plate 1 and steel plate 2 are leveled by rolling machine;

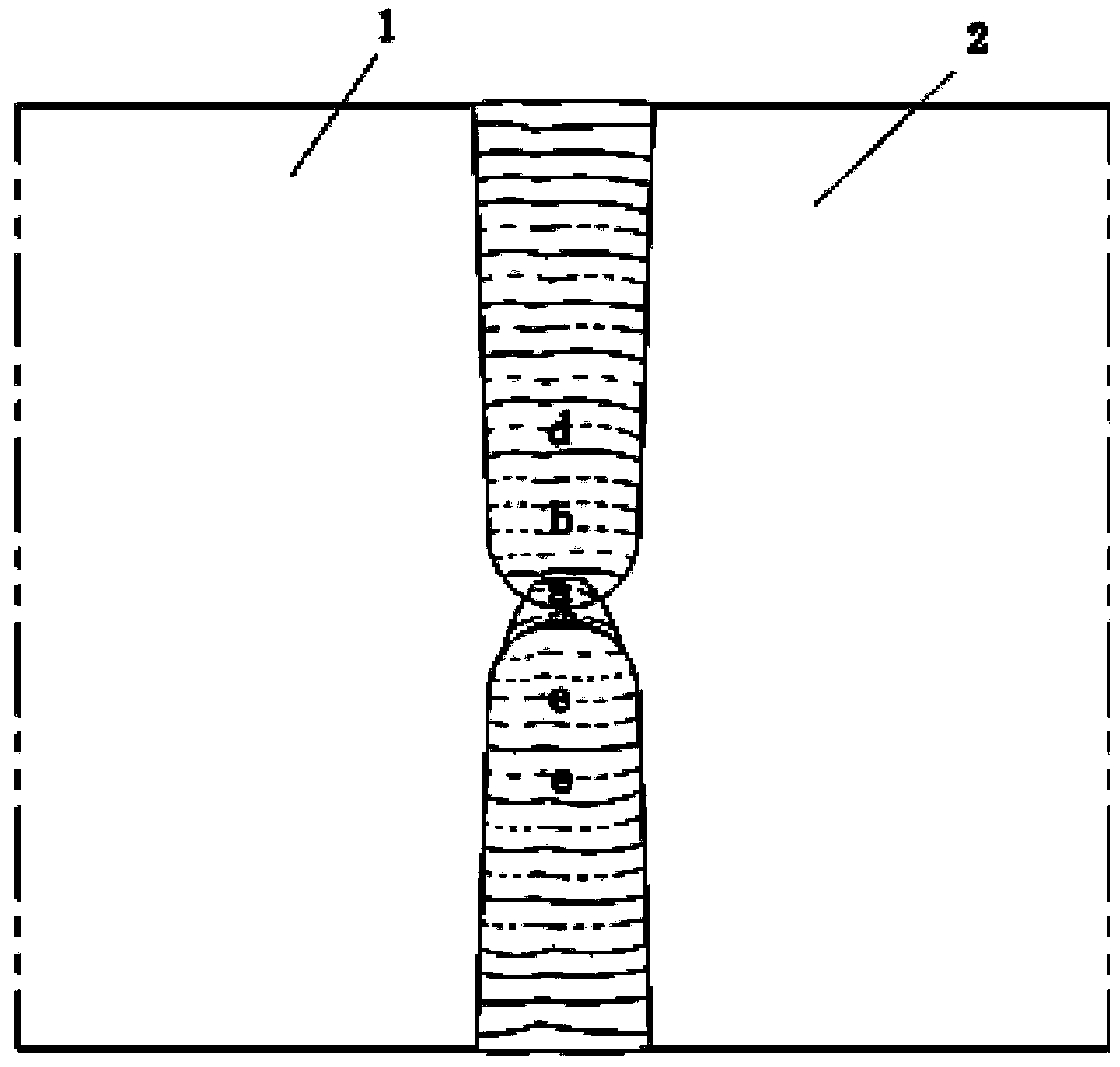

[0044] 3) The splicing edge of steel plate 1 and steel plate 2 is machined to open a welding g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com