Semi-finished dough cake packing device

A technology for semi-finished products and noodle cakes, applied in packaging, transport packaging, multiple packages, etc., can solve the problems of difficult control of packaging quality, damaged pasta, and restrictions on the development of semi-finished pasta, and achieve the effect of accelerating packaging efficiency and high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

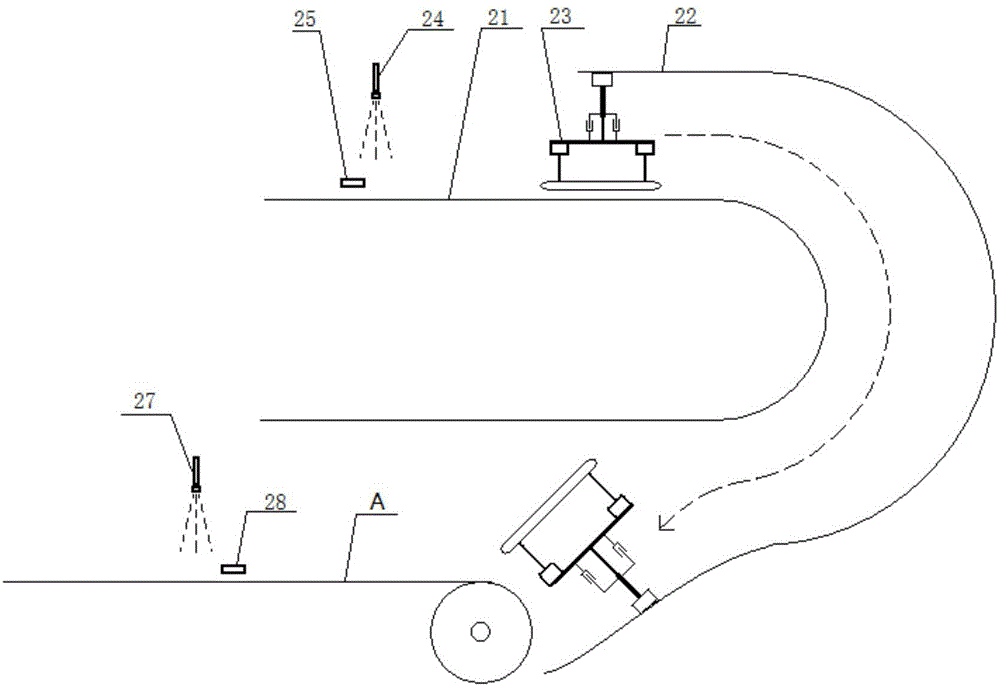

[0031] see figure 1 It can be seen that the semi-finished dough turning device mainly includes the first conveyor belt 21, the accompanying track 22, the accompanying turning mechanism 23, the first oil injection mechanism 24, the first laser induction mechanism 25, the second oil injection mechanism 27 and the second oil injection mechanism. Laser sensing mechanism 26. Wherein the first conveyor belt 21 connects the semi-finished dough cake production line, generally the processed semi-finished dough cake is placed on the first conveyor belt by manual mode, and the first conveyor belt 21 is positioned at the top of the conveyor belt before the semi-finished dough cake production line. Three oil injection mechanisms, such a structure can mark the position of the cakes, because this device has strict requirements on the spacing of each dough cake on the first conveyor belt 21, through such markings, it is convenient for the staff to place the cakes at a suitable distance posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com