Coal syngas circulation gas free methanation technology

A coal-to-synthesis gas and methanation technology, which is applied in the chemical industry, can solve the problems of increasing the power consumption of circulating gas and increasing equipment investment, and achieve the effects of improving energy utilization, reducing steam consumption, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

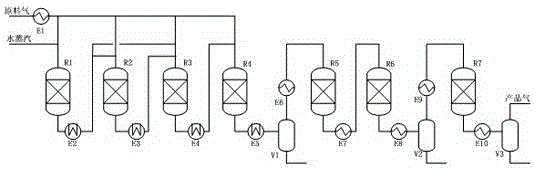

[0023] See the schematic diagram of this process figure 1 ,like figure 1 Show, pressure 3.5MPa, 100000Nm 3 / H's synthetic gas and synthetic gas in the synthetic gas is less than 0.1 ppm, f = (n H2 -N CO2 ) / (n CO +n CO2 ) = 3.005, the composition of the specific synthetic gas (volume percentage, wet base) is: H 2 : 64.00, CH 4 : 14.30, CO: 20.10, CO 2 : 0.90, n 2 : 0.50, h 2 O: 0.30.Raw gas gas enters the first, second, third, and fourth methane reactors according to 0.22, 0.15, 0.25, and 0.38.A methane reaction is performed in a methane reactor.The gas after the reaction of the first methane reactor is 630 ° C, then enters the waste pot for cooling, and the spacious steam is used.Enter the second and third methane reactors, one of which one group of first methane reactor exports is mixed with the second raw material gas to enter the second methane reactor for methane reaction.The temperature of the gas of the di methane reactor is 630 ° C to enter the waste pot for cooling, and th...

Embodiment 2

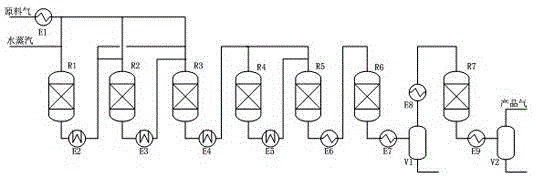

[0025] Example of this embodiment figure 2 The process shown in process is carried out, the pressure is 3.5MPa, 100000nm 3 / H's synthetic gas and synthetic gas in the synthetic gas is less than 0.1 ppm, f = (nH2 -N CO2 ) / (n CO +n CO2 ) = 3.005, the composition of the specific synthetic gas (volume score, wet) is: H 2 : 64.00, CH 4 : 14.30, CO: 20.10, CO 2 : 0.90, n 2 : 0.50, h 2 O: 0.30.The raw material gas enters the first, second, and third methane reactors according to 0.32, 0.21, and 0.47 points.In the device, methane reactions are performed.The gas (temperature 650 ° C) after the reaction of the first methane reactor was cooled to cool the pan, and the spacious steam was produced., The third methane reactor, one of the first methane reactors exporting the gas with the second raw material gas (temperature 260 ° C), enters the second methane reactor for methane reactions, and the second methane isThe gas (temperature 650 ° C) of the reactor enters the waste pot for cooling and ...

Embodiment 3

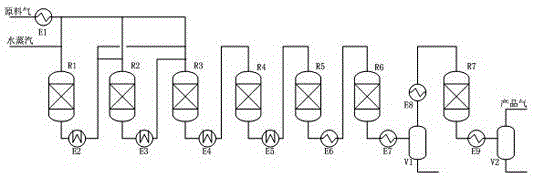

[0027] Example of this embodiment image 3 The process shown, the pressure 3.5MPa, 100000nm 3 / H's synthetic gas and synthetic gas in the synthetic gas is less than 0.1 ppm, f = (n H2 -N CO2 ) / (n CO +n CO2 ) = 3.005, the composition of the specific synthetic gas (volume score, wet) is: H 2 : 64.00, CH 4 : 14.30, CO: 20.10, CO 2 : 0.90, n 2 : 0.50, h 2 O: 0.30.The raw material gas enters the first, second, and third methane reactors according to 0.32, 0.21, and 0.47 points.In the device, methane reactions are performed.The gas (temperature 650 ° C) after the reaction of the first methane reactor was cooled to cool the pan, and the spacious steam was produced., The third methane reactor, one of the first methane reactors exporting the gas with the second raw material gas (temperature 260 ° C), enters the second methane reactor for methane reactions, and the second methane isThe gas (temperature 650 ° C) of the reactor enters the waste pot for cooling and has a gap in the steam; the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com