Precast Concrete Structural Components and Construction Horizontal Connection Method Between Components

A technology of precast concrete and structural components, applied in the direction of construction and building structure, can solve the problems affecting the wide application of precast concrete structures, difficult to guarantee the connection performance, complicated connection procedures, etc. The effect of strong relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

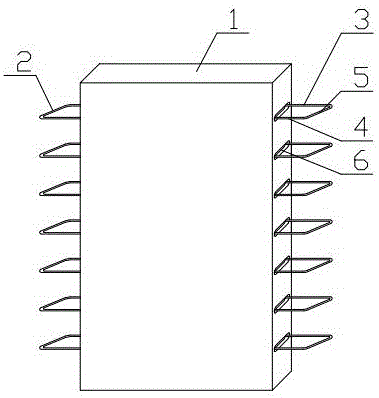

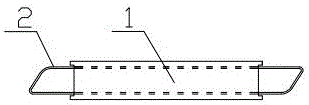

[0027] A precast concrete structural member, which consists of: a precast concrete member body 1, a set of horizontal steel bars 2 pre-embedded in the precast concrete member, the extension part of the horizontal steel bars is trapezoidal, the precast concrete The two sides of the component respectively have a set of grooves 6 through which the horizontal steel bars pass.

Embodiment 2

[0029] According to the precast concrete structural member described in the first embodiment, the horizontal rebar extension portions are respectively formed by the long-side rebar segment 3, the hypotenuse rebar segment 4 and the short-side rebar segment 5 connected together.

Embodiment 3

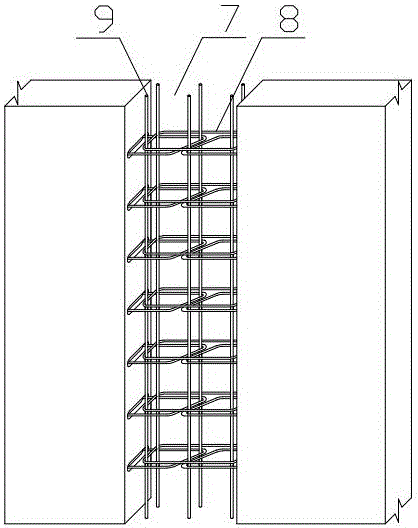

[0031] A method for building construction horizontal connection between precast concrete structural members described in embodiment 1 or 2, in which a post-pouring belt 7 is set at the junction of two precast concrete member bodies, and the horizontal steel bars are all located at the rear At the pouring belt, the long-side bar section of the horizontal steel bar of one piece of the precast concrete component body corresponds to the short-side bar section of the horizontal steel bar of the other precast concrete component body, and a rectangle is placed on the top of the horizontal steel bar. Enclosed stirrup 8; two pieces of the precast concrete component body of the hypotenuse reinforcement section are bound; the post-injection longitudinal bar 9 is set at the post-cast belt; the post-injection longitudinal reinforcement, the horizontal steel bar And the rectangular closed stirrups work together to form a hidden column, and after pouring concrete at the post-pouring belt, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com