Novel sand mixing skid and control system thereof

A control system and sand mixing technology, which is applied in the fields of production fluids, wellbore/well components, fluid pressure actuating devices, etc., can solve the problems of high cost and incompatibility of sand mixing vehicles, save production costs and ensure quality , easy to operate and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

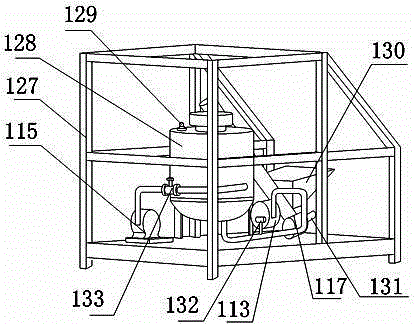

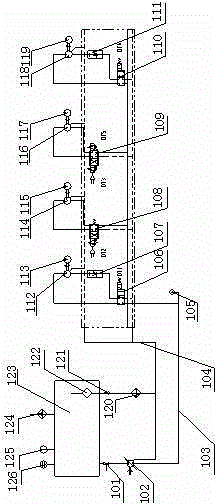

[0017] Such as figure 1 As shown, a new sand mixing skid and its control system include a frame 127, and the frame 127 is provided with a discharge pump 113, a suction pump 115, a mixing tank 128, and a sand supply device 117. The mixing tank 128 is provided with an agitator 119, the liquid suction pump 115 is connected to the mixing tank 128 through a pipeline, and the pipeline connecting the liquid suction pump 115 and the mixing tank 128 is provided with an inflow flow meter 133, the described The drain pump 113 is connected to the bottom of the mixing tank 128 through a pipeline, and the pipeline connecting the drain pump 113 and the mixing tank 128 is provided with a sand-carrying pump pressure sensor 132, and the outlet end of the sand supply device 117 is located at the inlet of the mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com