System and method for cooperatively controlling supercharged diesel engine EGR valve, VGT and throttle valve

An EGR valve and collaborative control technology, applied in electrical control, engine control, mechanical equipment, etc., can solve problems such as complex coupling relationship, difficulty in recirculating exhaust gas, and difficulty in optimized application, so as to reduce pumping loss, reduce calibration workload, Improve the effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

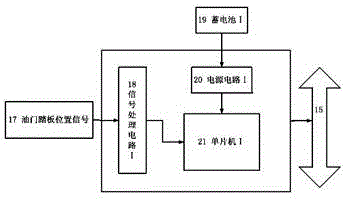

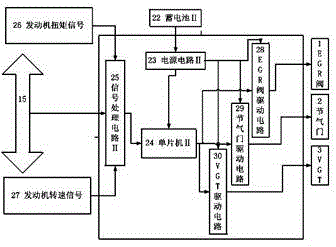

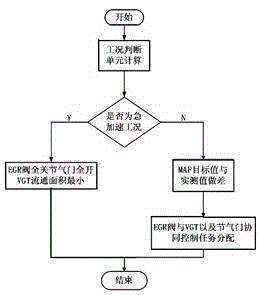

[0037] like figure 1 As shown, the supercharged diesel engine EGR valve, VGT and throttle cooperative control system of the present invention consists of an electronically controlled EGR valve 1, a throttle valve 2, a variable geometry supercharger (VGT) 3, a compressor 4, a cooler 5, Tee 6, engine exhaust manifold 7, engine intake manifold 8, EGR valve VGT throttle electronic control unit 9, operating condition judgment unit 10, air flow sensor 11, engine speed sensor 12, accelerator pedal position sensor 13, engine torque The sensor 14, the CAN bus 15 and the start switch 16 are composed, wherein the accelerator pedal position sensor 13 is connected with the working condition judging unit 10; the air flow sensor 11, the engine speed sensor 12 and the engine torque sensor 14 are connected with the EGR valve VGT throttle electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com