A miniature sound-absorbing accumulator for shock absorbers

A technology of shock absorbers and accumulators, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of large moving range, low service life and wear of floating pistons, and improve the overall performance and service life, improve service life and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

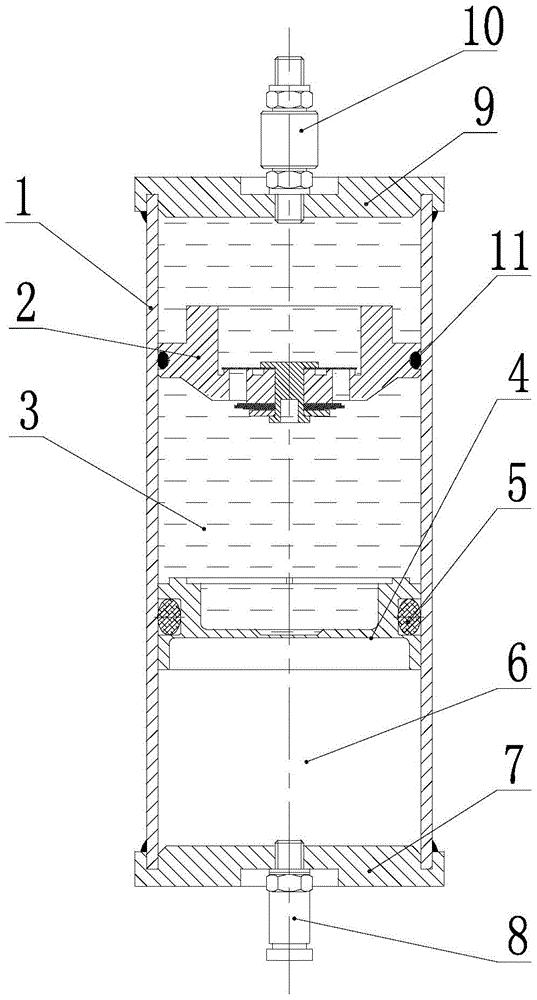

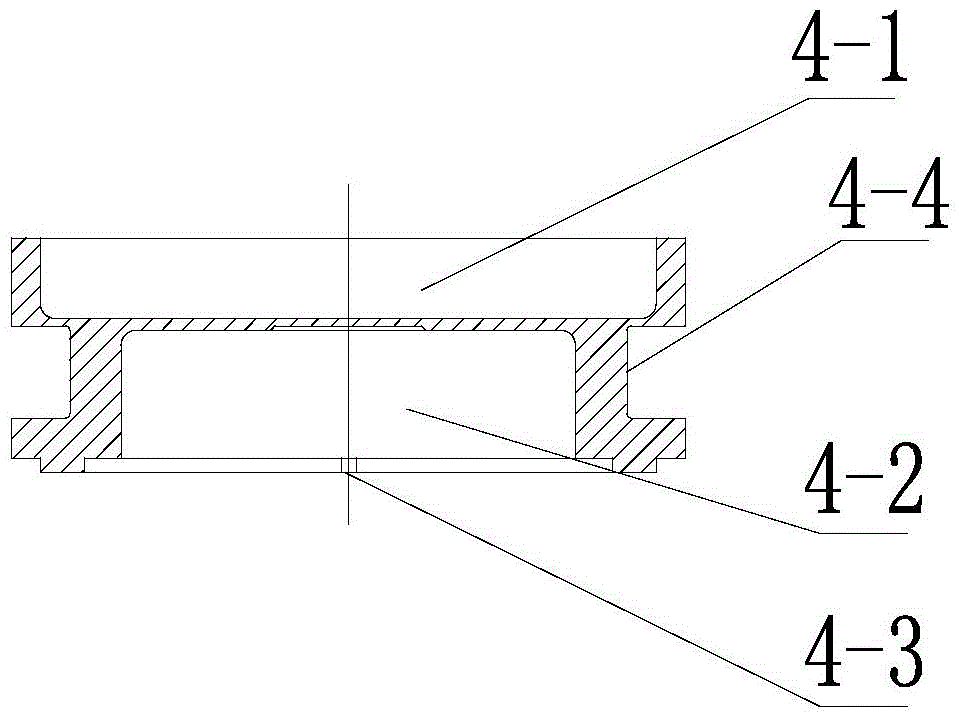

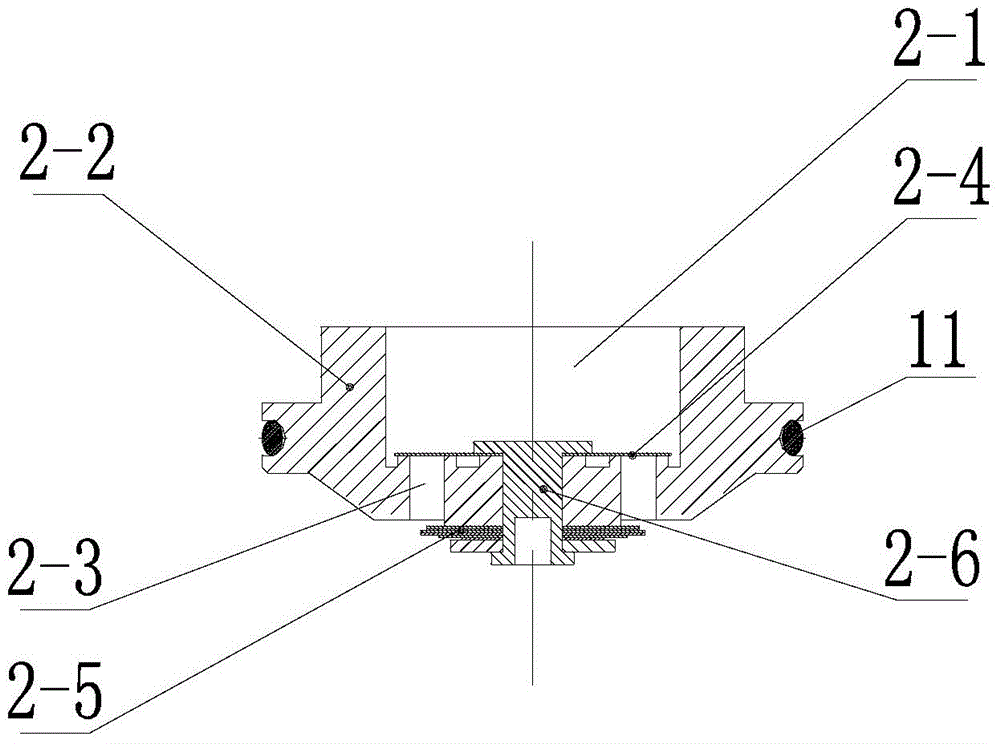

[0022] The present embodiment provides a miniature sound-absorbing accumulator for shock absorbers, the structure of which is as follows: Figure 1 to Figure 3 As shown, it includes the working cylinder 1 and the upper and lower sealing end caps fixedly sealed at both ends of the working cylinder. The upper sealing end cap 9 is provided with a quick joint 10 communicating with the rodless chamber of the shock absorber, and the lower sealing end cap 7 is provided with The self-sealing pneumatic joint 8 is provided with a floating piston 4 fitted on the inner wall of the working cylinder through a sealing ring in the cavity of the working cylinder, and a liquid filling is fixedly installed on the working cylinder between the upper sealing end cover 9 and the floating piston 4 The working end surfaces of valve 2, liquid filling valve 2 and floating piston 4 are all perpendicular to the central axis of the working cylinder; shock absorbing oil 3 is filled between the floating pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com