A stabilizing device for eliminating vibration of bellows compensator

A technology of compensator and bellows, which is applied in expansion compensation devices for pipelines, pipe components, pipeline protection, etc., can solve the problems of compensator life impact and other problems, and achieve the effects of preventing fatigue damage, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

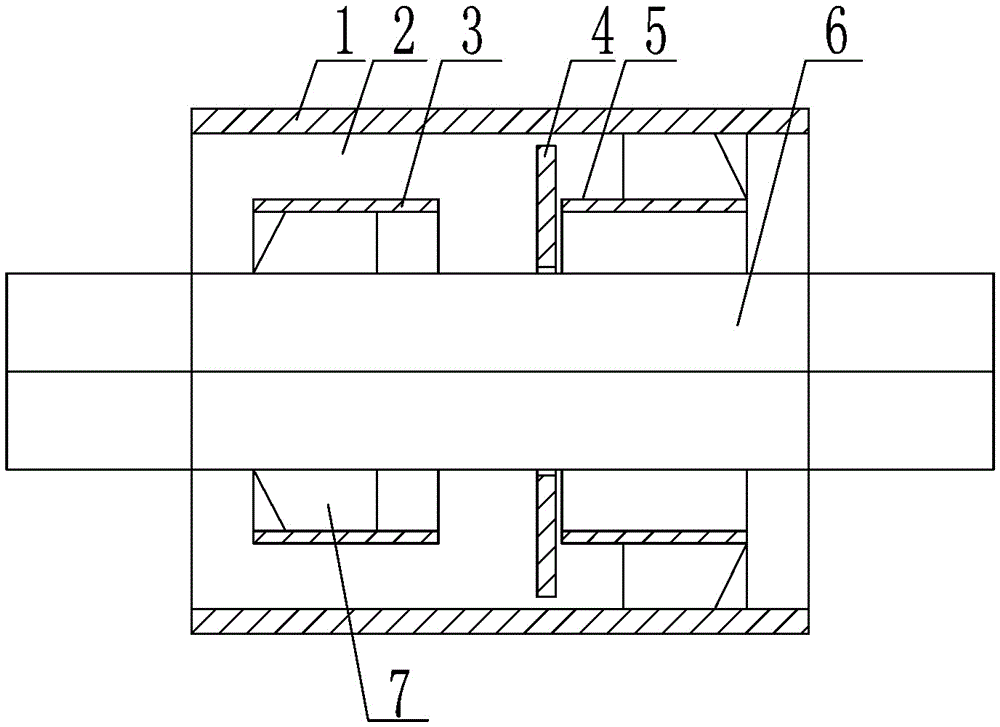

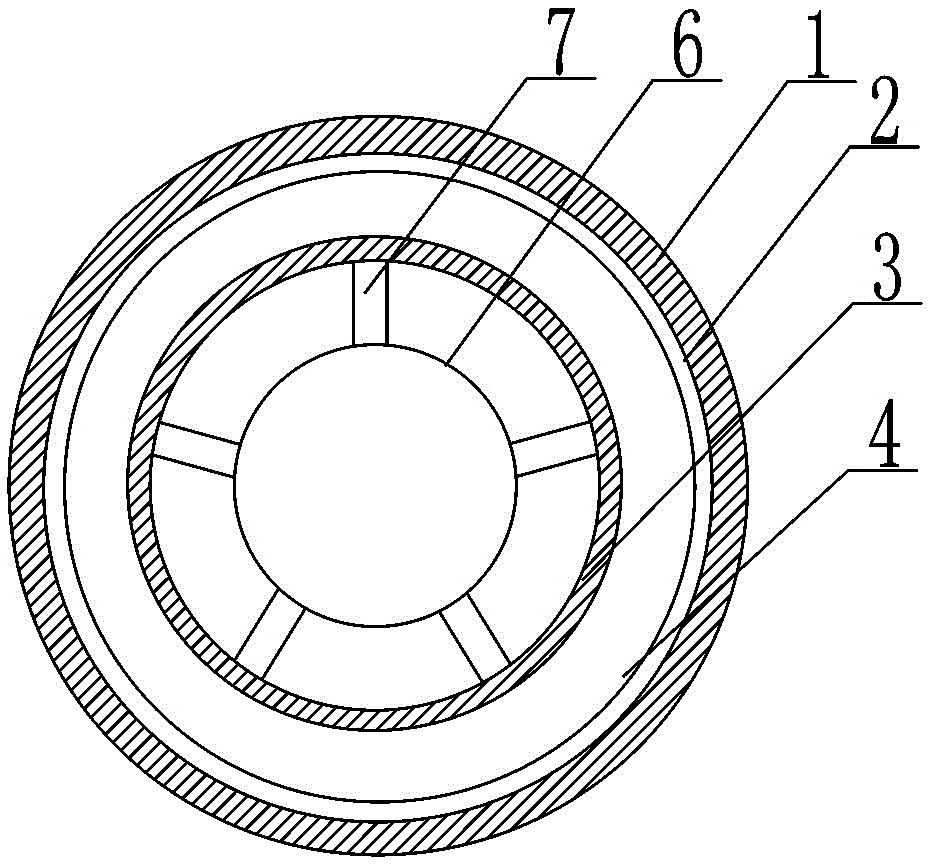

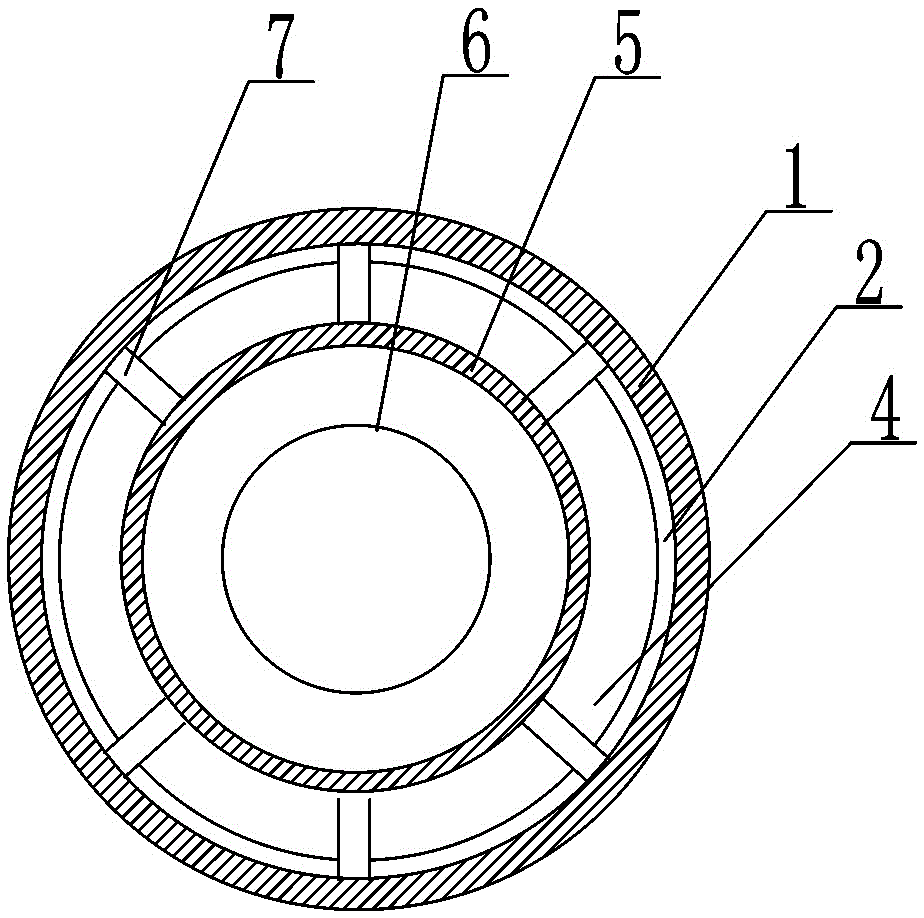

[0011] See attached figure 1 , the present invention includes a steam pipe 6 provided with an insulating layer 2; the steam pipe 6 is provided with a thrust ring 3, a baffle plate 4 and a bearing ring 5; 6, the insulation layer 2 is provided with a casing 1, the baffle 4 is a ring set on the steam pipe 6, and its outer circle is larger than the diameter of the thrust ring 3 and the bearing ring 5, the baffle 4 and the steam pipe 6 is a sliding connection; the thrust ring 3 and the bearing ring 5 are sleeves arranged on both sides of the baffle plate 4, and the thrust ring 3 and the bearing ring 5 are fixedly connected to the steam pipe 6 and the casing 1 by the plate 7 respectively. ; The distance between the thrust ring 3 and the bearing ring 5 is ΔL=α×L×(t 2 -t 0 ), where L is the length of the compensation pipe section; α is the linear expansion coefficient of the steel; t 2 is the lower limit achievable during the working period of the compensation pipe section; t 0 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com