Temperature-resistant clay anti-swelling agent for acidification in oil field and preparation method thereof

A technology of anti-swelling agent and clay, which is applied in the field of temperature-resistant clay anti-swelling agent for oil field acidification and its preparation, can solve the problems that clay anti-swelling agent is not suitable for high-temperature acidification environment, and achieve easy acquisition, transportation and storage, and temperature-resistant Good performance and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: clay antiswelling agent B 1 and its preparation method

[0025] (1) Clay anti-swelling agent B 1 The composition, components and molecular formula are as follows:

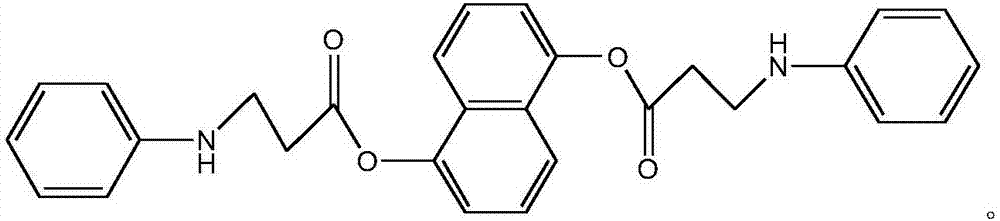

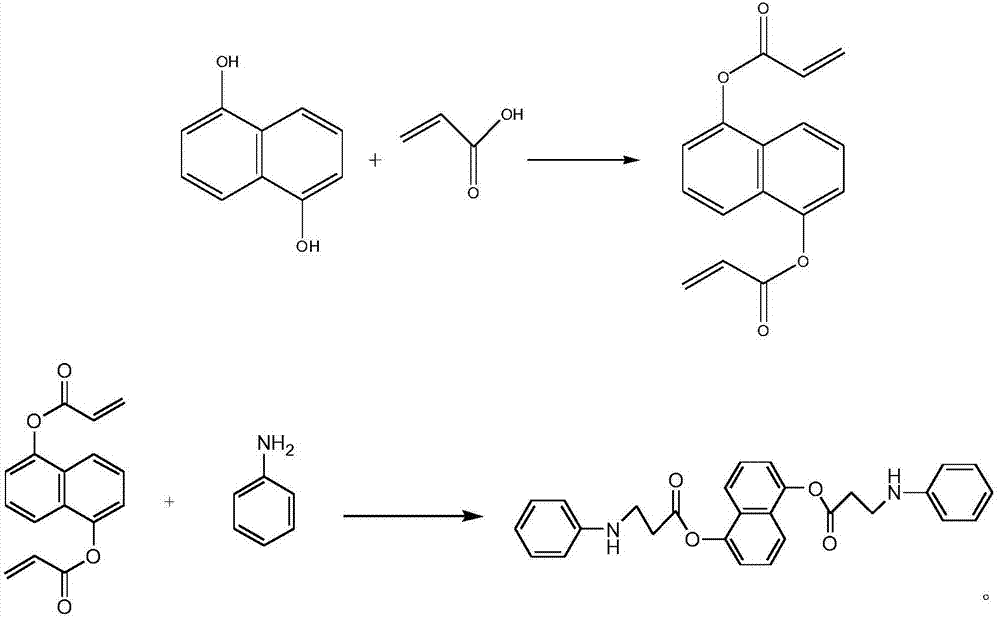

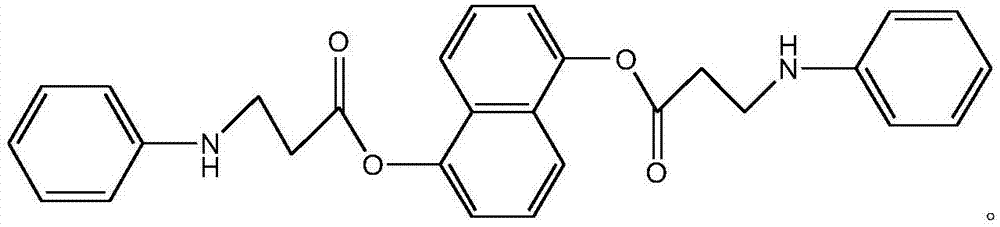

[0026] Clay anti-swelling agent B 1 The intermediate is formed by reacting 1 mol of 1,5-dihydroxynaphthalene with 0.9 mol of acrylic acid, and then reacted with 1.1 mol of aniline through amidation reaction. Its molecular formula is as follows:

[0027]

[0028] (2) Clay anti-swelling agent B 1 The preparation method is as follows:

[0029] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, add 1mol of 1,5-dihydroxynaphthalene and 0.9mol of acrylic acid, raise the temperature to 60°C, and then slowly add 640.68g of Sodium hydroxide, after the sodium hydroxide is completely added, heat up to 110°C at a rate of 5°C per minute, keep the stirring rate constant, react at a constant temperature for 5h, then turn off the heat source, cool down to room...

Embodiment 2

[0034] Embodiment 2: clay antiswelling agent B 2 and its preparation method

[0035] (1) Clay anti-swelling agent B 2 The composition, components and molecular formula are as follows:

[0036] Clay anti-swelling agent B 2 The intermediate is formed by reacting 1 mol of 1,5-dihydroxynaphthalene with 1.2 mol of acrylic acid, and then reacted with 1.2 mol of aniline through amidation reaction. Its molecular formula is as follows:

[0037]

[0038] (2) Clay anti-swelling agent B 2 The preparation method is as follows:

[0039] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, add 1mol of 1,5-dihydroxynaphthalene and 1.2mol of acrylic acid, raise the temperature to 65°C, and slowly add 700.56g of Sodium hydroxide, after the sodium hydroxide is completely added, heat up to 120°C at a rate of 8°C per minute, keep the stirring rate constant, react at a constant temperature for 6h, then turn off the heat source, cool down to room temp...

Embodiment 3

[0043] Embodiment 3: clay antiswelling agent B 3 and its preparation method

[0044] (1) Clay anti-swelling agent B 3 The composition, components and molecular formula are as follows:

[0045] Clay anti-swelling agent B 3 The intermediate is formed by reacting 1 mol of 1,5-dihydroxynaphthalene with 1.5 mol of acrylic acid, and then reacted with 1.2 mol of aniline through amidation reaction. Its molecular formula is as follows:

[0046]

[0047] (2) Clay anti-swelling agent B 3 The preparation method is as follows:

[0048] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, add 1mol of 1,5-dihydroxynaphthalene and 1.5mol of acrylic acid, raise the temperature to 70°C, and slowly add 752.35g of Sodium hydroxide, after the sodium hydroxide is completely added, heat up to 135°C at a rate of 12°C per minute, keep the stirring rate constant, react at a constant temperature for 8h, then turn off the heat source, cool down to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com