Small collimation system used for single-core surface mounted device LED

A single-chip, collimated technology, applied in the parts of lighting devices, lighting devices, light sources, etc., can solve the problems of insufficient energy concentration, large divergence angle of high-power LEDs, and low utilization rate of light energy, so as to improve the utilization rate. , The effect of small lens thickness and short optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

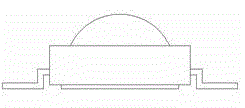

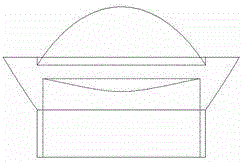

[0019] The system includes LED collimating lens, single-chip SMD LED, and LED fixing device; LED collimating lens consists of five surfaces, which are divided into two parts: refraction part and internal total reflection part. The first surface is the refraction surface of light with a large angle from the optical axis, the second surface is the total reflection surface of internal light, the third surface is the exit surface of total reflection light, and the fourth surface is the surface of light with a small angle from the optical axis The first refraction surface, the fifth surface is the second refraction surface of small-angle light. The large-angle light emitted by the LED chip is refracted by the first surface and then completely reflected by the second surface, so that the light is parallel to the optical axis and emitted by the third surface; the angle of the small-angle light is reduced after being refracted by the fourth surface After being refracted by the fifth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com