A Chain Plate Conveying Coal Ball Heat Transfer Oil Dryer

A heat-conducting oil and dryer technology, applied in progressive dryers, dryers, drying solid materials, etc., can solve the problems of reduced briquettes pass rate, reduced drying efficiency, increased manufacturing costs, etc., to improve the qualified rate of finished products and Drying efficiency, preventing briquettes from burning, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

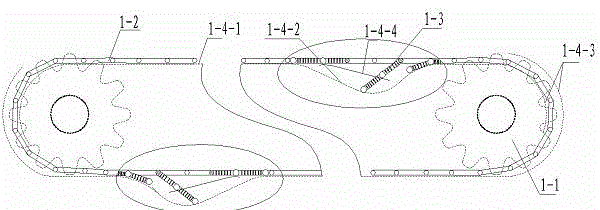

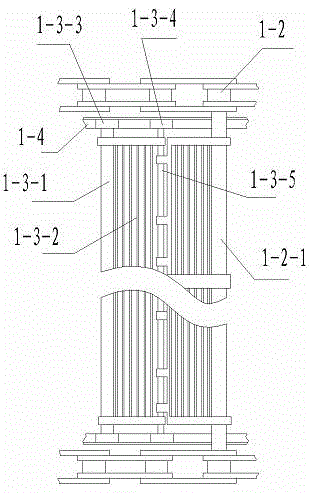

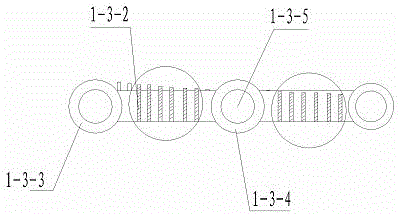

[0026] See attached figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, a chain-plate conveying briquette heat-conducting oil dryer, including a heat-insulating shell, a group of vertically distributed chain-plate conveying mechanisms arranged in the heat-insulating shell, positioned at The feed conveyor belt 2 on the upper side of the upper chain plate conveying mechanism, the discharge port 3 positioned on the lower side of the lower chain plate conveying mechanism, the heating device and the waste heat utilization device, the chain plate conveying mechanism 1 includes a double drive chain structure And its supporting chain wheel 1-1, the bearing chain plate 1-3 positioned on the chain shaft 1-2-1 and the guide rail 1-4 supporting the chain plate wheel 1-3-3, its key is: The carrying chain plate 1-3 is a hollow structure composed of a frame 1-3-1 and grid bars 1-3-2, and the hinge is positioned on the chain shaft 1-2-1; the structure of the guide rail 1-4 is divided into The upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com