System for measuring thermal insulation effects of metallurgy thermal insulation material

A technology of thermal insulation material and thermal insulation cotton, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., to achieve the effect of less test sample consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

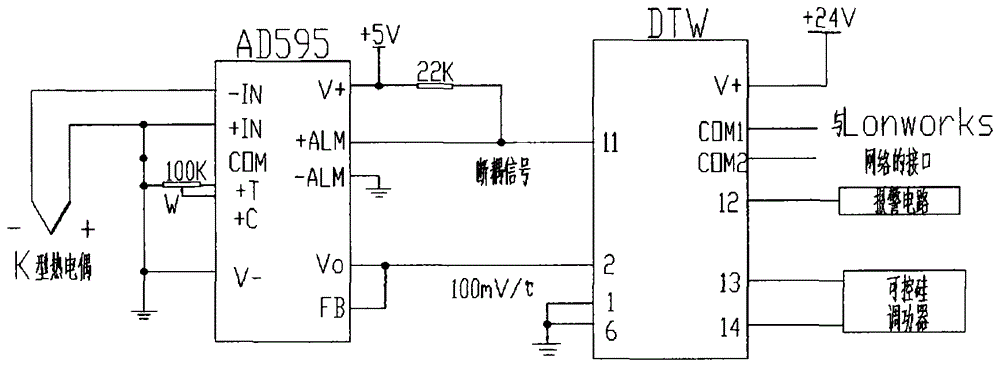

[0020] Further description will be made below in conjunction with accompanying drawings. The model of the automatic temperature controller 8 is,

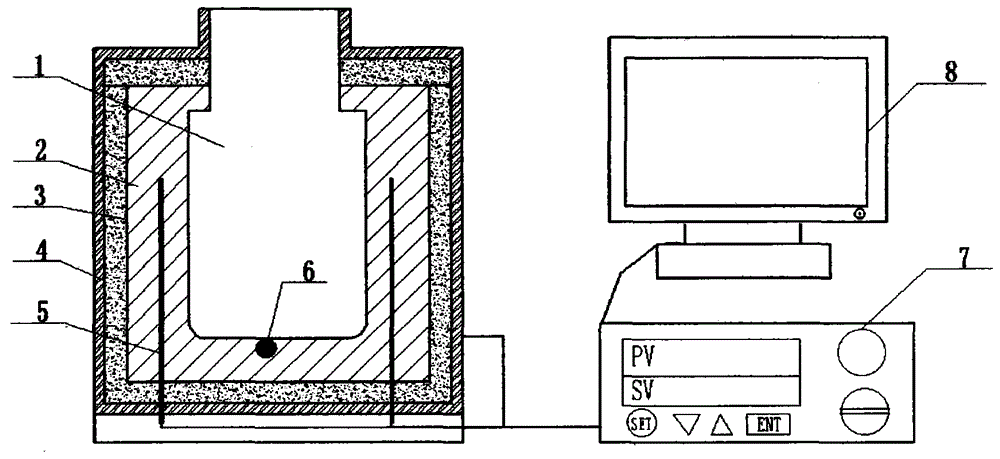

[0021] Structural schematic diagram of the present invention sees attached figure 1 , The system for measuring the thermal insulation effect of metallurgical thermal insulation materials is divided into: a test furnace, an automatic temperature control system and a computer data processing system. The test furnace body is a cylinder. The furnace shell 4 is made of stainless steel with a thickness of 1.5 mm. Furnace 1 is a cylinder, the diameter of the upper opening is 120mm, the diameter of the main body of furnace 1 is 150mm, the furnace wall 2 and the bottom of furnace 1 are integral, and they are all made of alumina fiber light refractory material. The thickness of the furnace wall is 100mm, and the thickness of the bottom is is 50mm. The side wall of the furnace 1 is symmetrically inlaid with silicon carbon rods 5 as heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com