Automatic detection equipment of fuel oil measuring system

An automatic detection and measurement system technology, applied in measurement devices, liquid/fluid solid measurement, testing/calibration devices, etc., can solve the problems of manual operation safety hazards, low test efficiency, and large human factors, and achieve the degree of intelligence High, simple operation, wide adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with the drawings and embodiments, but the invention is not limited to the scope of the embodiments.

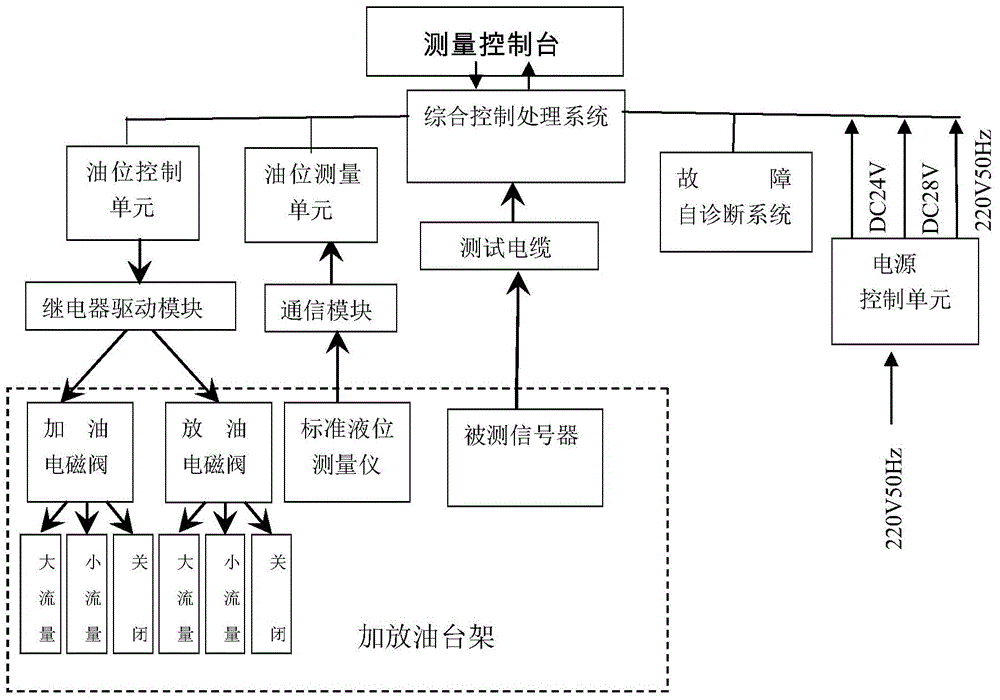

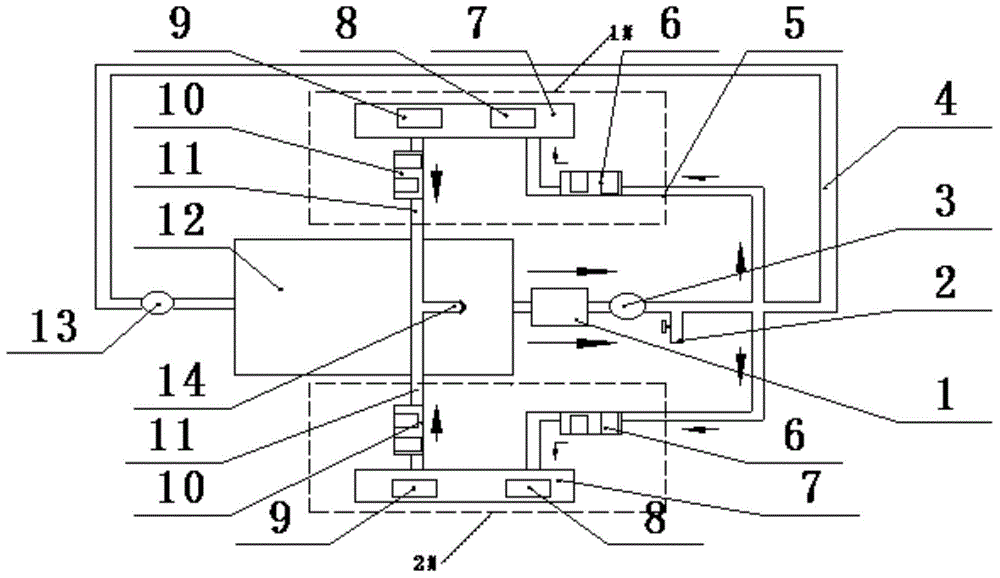

[0014] refer to figure 1 . In the embodiments described below, the automatic oil filling and discharging detection electrical detection device mainly includes a fuel filling and discharging platform and a measurement console, and the measuring console is connected to the corresponding cable socket on the oil filling and discharging platform through a special test cable. The measurement console includes an oil level measurement unit, an oil level control unit, a fault self-diagnosis system and a power control unit that are respectively connected to an integrated control processing system (mainly referring to an industrial control computer). The refueling and discharging platform contains a refueling solenoid valve 6 and a fuel discharging solenoid valve 10 for controlling the fuel flow and closing the fuel fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com