Method for determining rolling curve for two-way rolling process of ring

A technology of curve equation and ring piece, applied in the field of rolling and forming processing of ring piece, can solve the lack of scientific method of rolling curve, no public report on the determination method of rolling curve, and no public report on the specific method and procedure of rolling curve. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

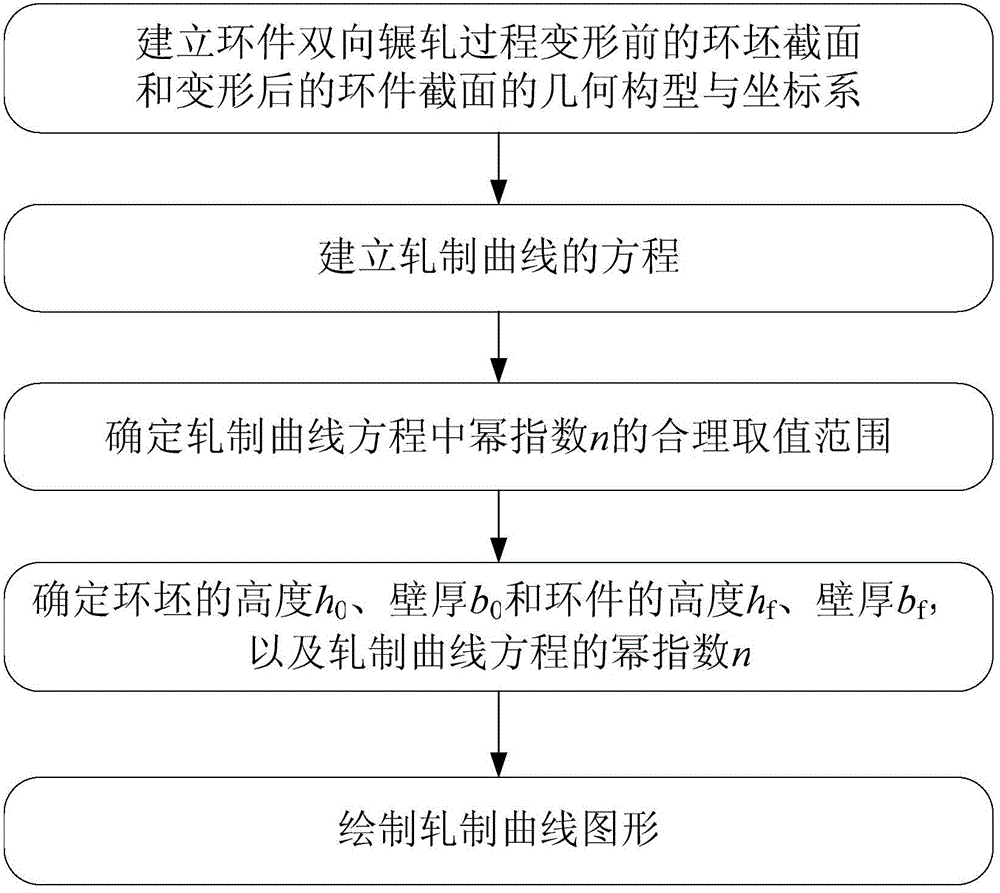

[0030] This embodiment is a method for determining the rolling curve of the bidirectional rolling process of the ring, and the specific steps are as follows:

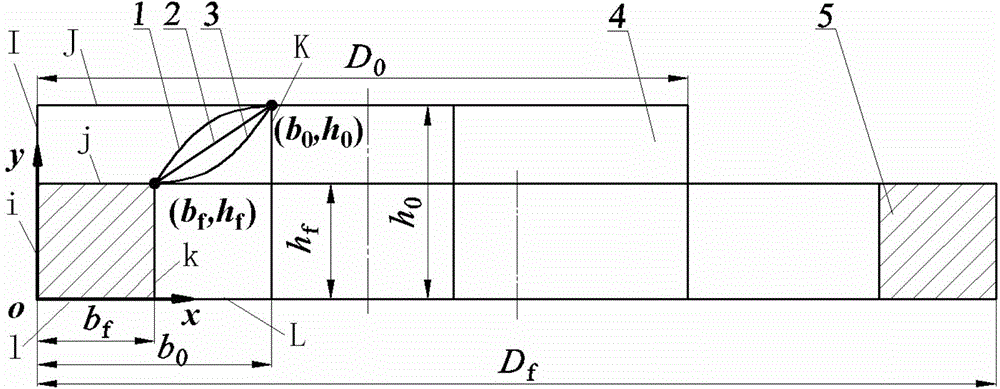

[0031] Step 1: Establish the geometric configuration and coordinate system of the ring blank section before deformation and the deformed ring section in the two-way rolling process of the ring. Wherein, the section of the ring blank is a rectangle surrounded by the first side I, the upper side J, the second side K, and the lower side L; the section of the ring is formed by the first side i, the upper side j, and the second side k and the rectangle enclosed by the lower side l.

[0032]The geometric configurations of the ring blank section and the ring section in the two-way rolling process of the ring are: the first side I of the ring blank section coincides with the first side i of the ring section; the lower edge L of the ring blank section coincides with the ring section The lower edge l of the section of the piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com