Integrated optimization method for arch truss chip mounter based on coevolution

A technology of co-evolution and optimization methods, applied in gene models, data processing applications, predictions, etc., can solve problems such as discounting of algorithm optimization results, failure to quickly obtain better optimization results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

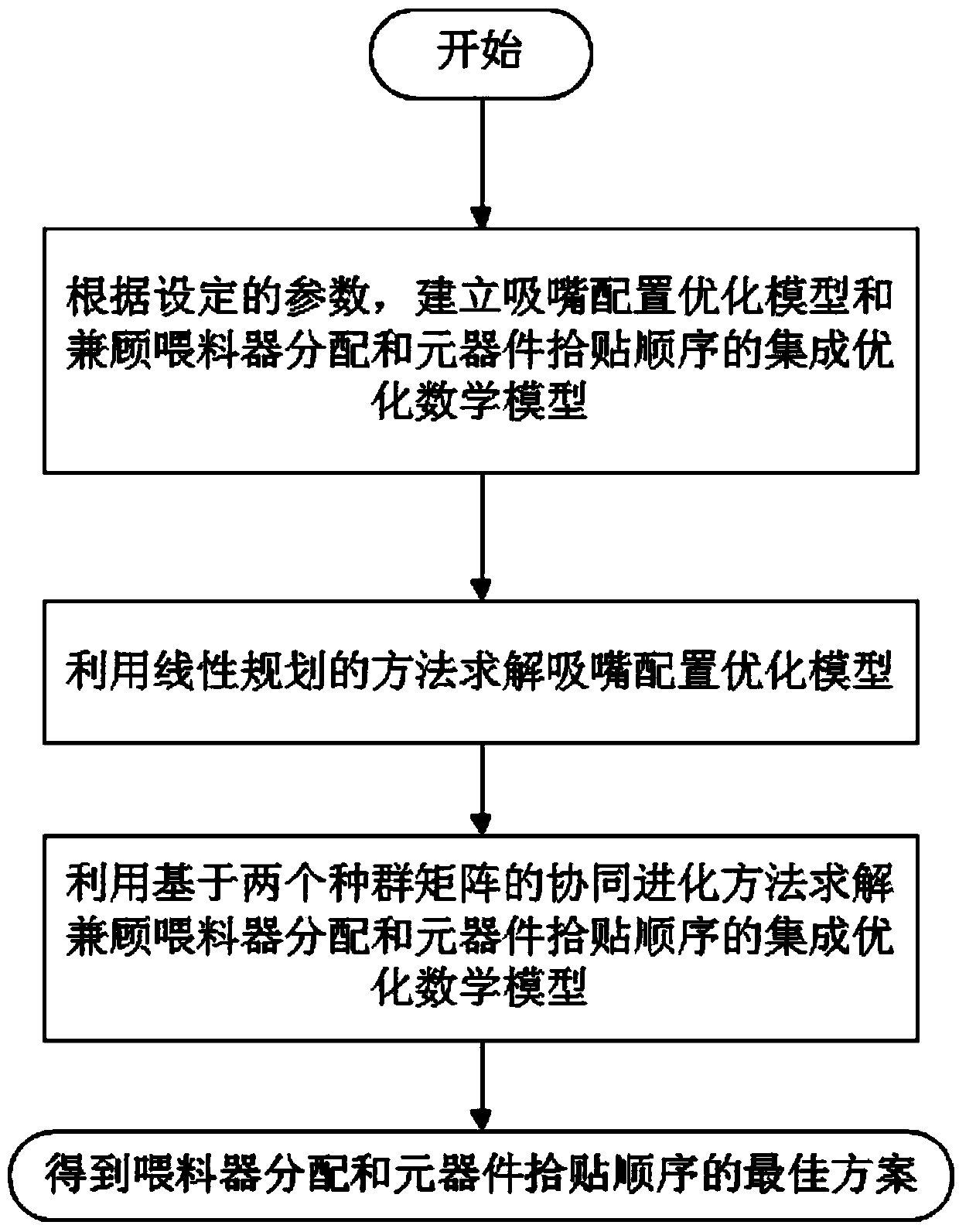

[0075] Such as figure 1 As shown, an integrated optimization method based on co-evolution of arch mounter includes the following steps:

[0076]Step 1, establish the nozzle configuration optimization model and the integrated optimization mathematical model that takes into account the feeder allocation and component picking sequence:

[0077] 1) if figure 2 It is the structural diagram of the arch type placement machine. For the arch type placement machine with H mounting heads, a PCB board is arranged on the workbench 3, and multiple placement heads 1 are arranged on the placement head mechanism. There is a suction nozzle 2 on the top, and a camera 4 for monitoring is provided on the workbench; a feeder 5 and a feeding trough 6 are respectively provided on the mechanism; the placement of components is completed in G pick-and-place cycles, A maximum of H components are placed in each pick-and-place cycle. And meet the following conditions: one feeder only supplies one kind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com