Force sensing analog system based on C-EPS structure

A technology of C-EPS and simulation system, which is applied in the field of resistance loading simulators. It can solve the problems of bulky driver simulators, distorted force sense, and inability to load vehicles, and achieve low cost, easy loading, and high mechanical precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

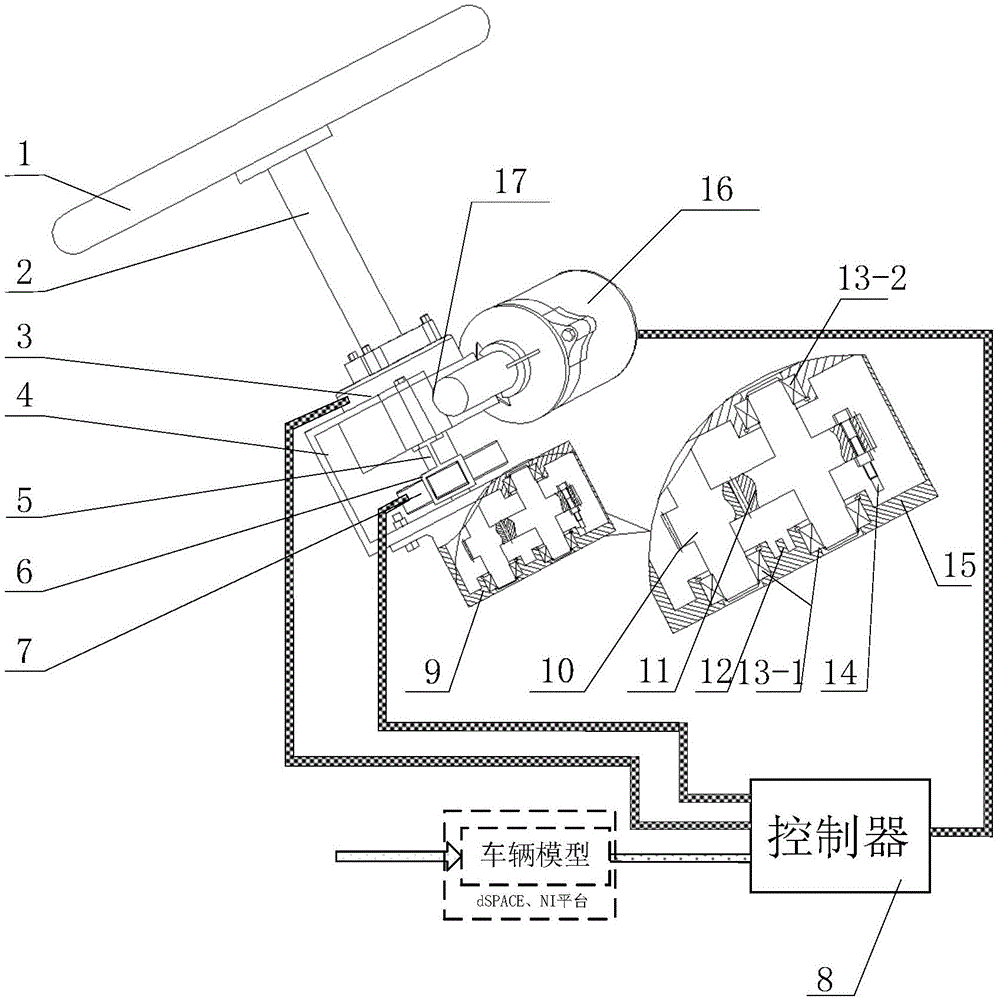

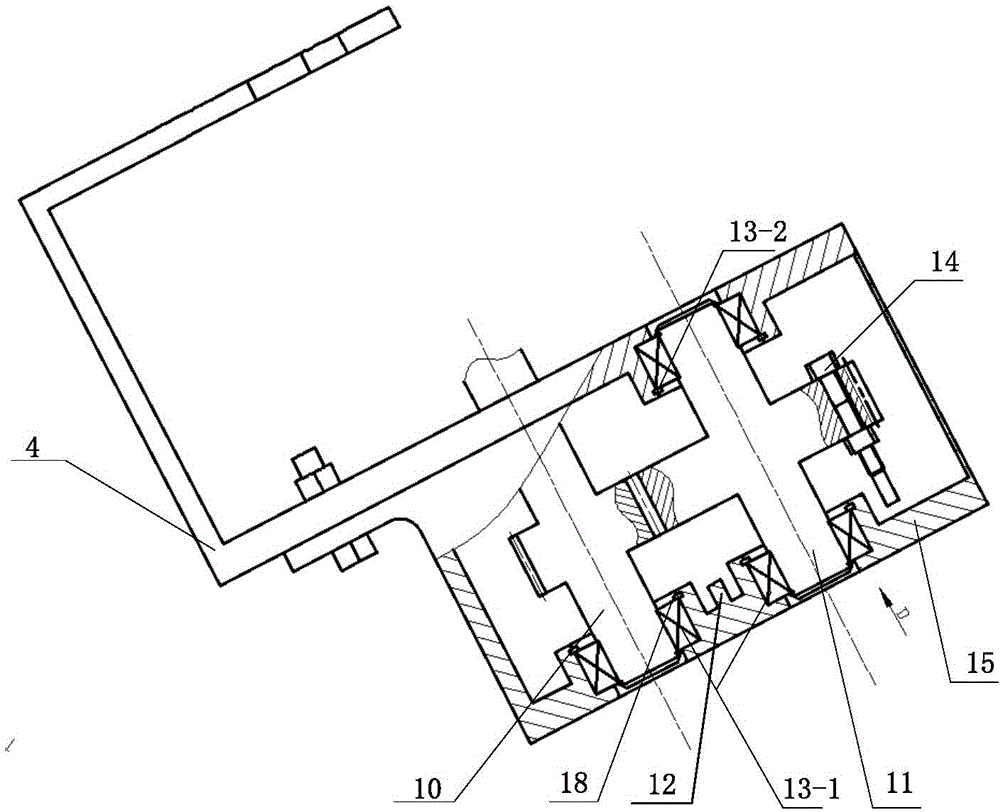

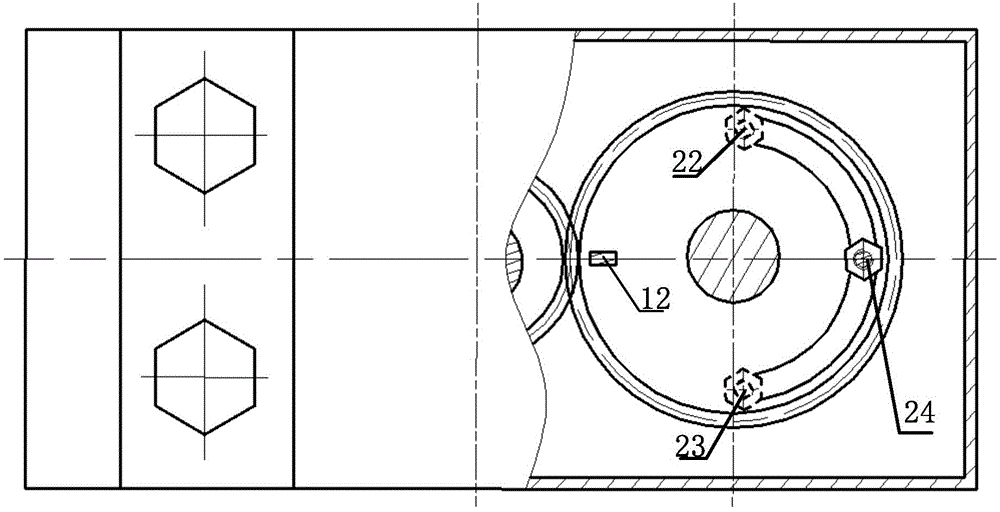

[0028] Such as figure 1 , Figure 4 , Figure 5 As shown, the present invention includes a steering wheel 1, a servo motor 16, a worm gear reduction mechanism 17, a limit device 9, a torque sensor 3, and a steering wheel angle sensor 7. The steering wheel angle sensor 7 is connected by the inner spline of the connecting shaft 5 and the outer spline of the end of the steering column tube 19, the axial fixation of the steering wheel angle sensor 7 is fixed by the sensor support 6, the wire harness square outlet of the steering wheel angle sensor 7 and The sensor support 6 cooperates and is tensioned with the screw 21. At the same time, it is fixed on the C-EPS shell with the screw 21. By connecting the shaft 5 and the sensor support 6, the sensor and the steering column tube maintain high-precision coaxiality.

[0029] Such as figure 2 , i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com