Metal holide lamp arc tube

A metal halide lamp and arc tube technology, applied in the field of electrical appliances, can solve problems such as complex manufacturing process, and achieve the effects of easy manufacturing, prolonging service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

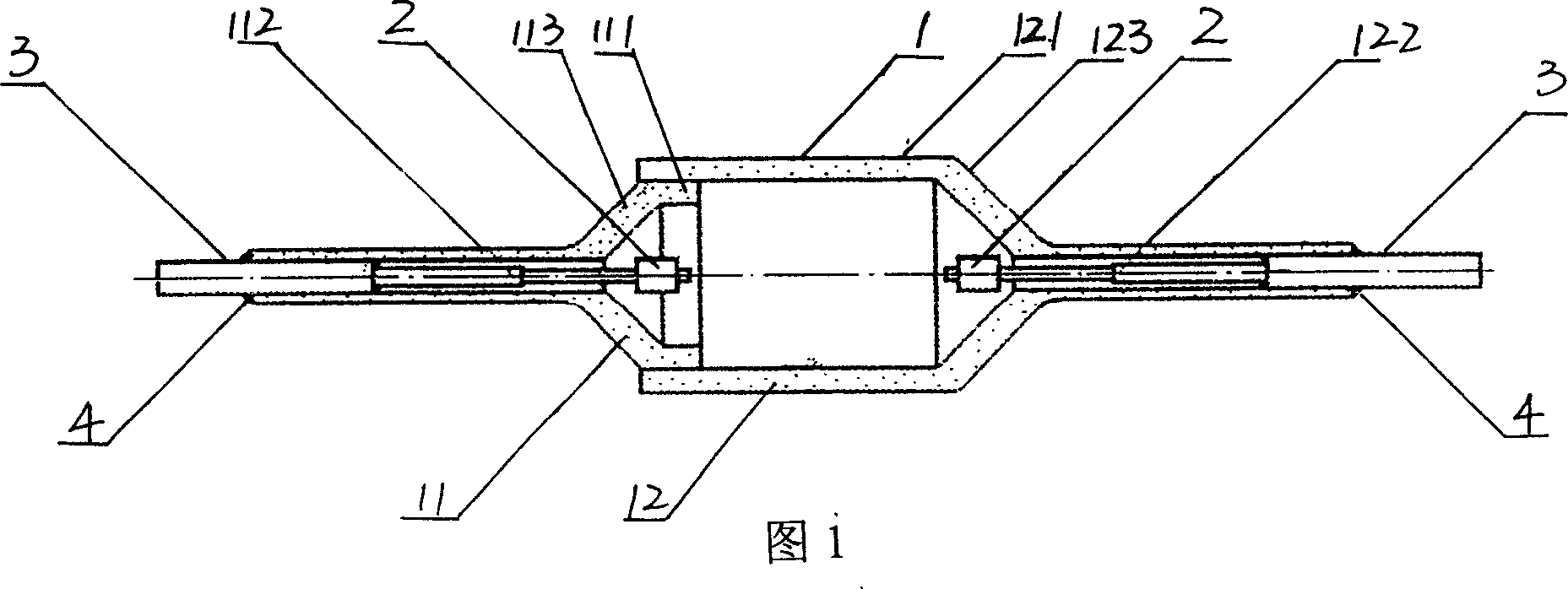

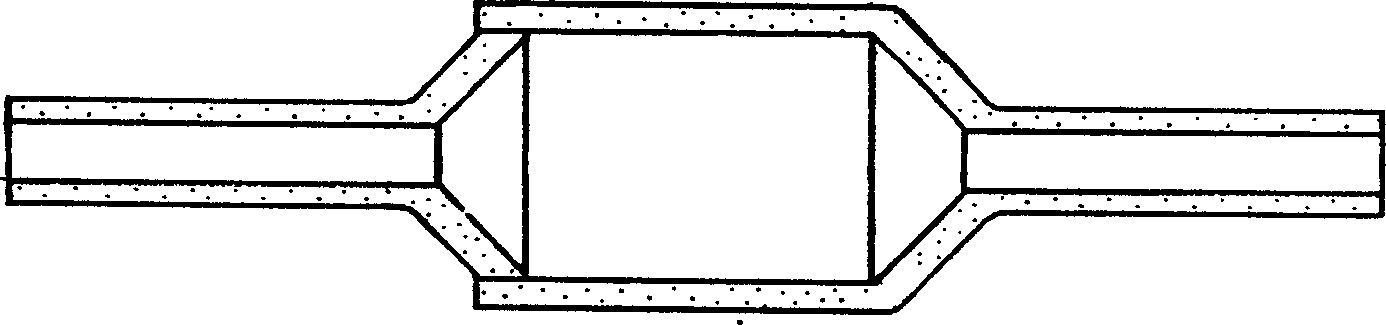

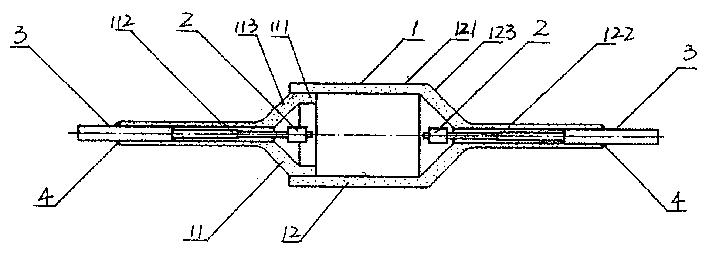

[0015] A metal halide lamp arc tube as shown in Fig. 1 has a casing 1, an electrode 2 is arranged inside the casing 1, a conductive lead 3 is arranged at the rear end of the electrode 2, the casing 1 is made of translucent alumina ceramics, the casing 1 It is formed by sintering a two-piece shell 11 and shell 12. The shell 11 is composed of a thicker cylinder 111, a slender tail pipe 112 and a conical transition tube 113. It is formed by one-time pressing with a mold. The shell 12 and the shell 11 It is similar in shape and consists of three parts: a thicker cylinder 121, a slender tail pipe 122 and a conical transition cylinder 123. It is formed by one-time pressing with a mold. The outer diameter of the thicker cylinder 111 is slightly larger than that of the thicker cylinder. 121, the length of the thicker cylinder 111 is shorter, the electrode 2 is arranged on the conical transition cylinder 113 and the conical transition cylinder 123, and the conductive lead 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com