Voltage-drop compensation method for power output lines and switch power supply

A technology of power output and switching power supply, which is applied in the fields of digital electronics, automatic control, analog electronics, and power electronics. defects, the effect of improving the load regulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

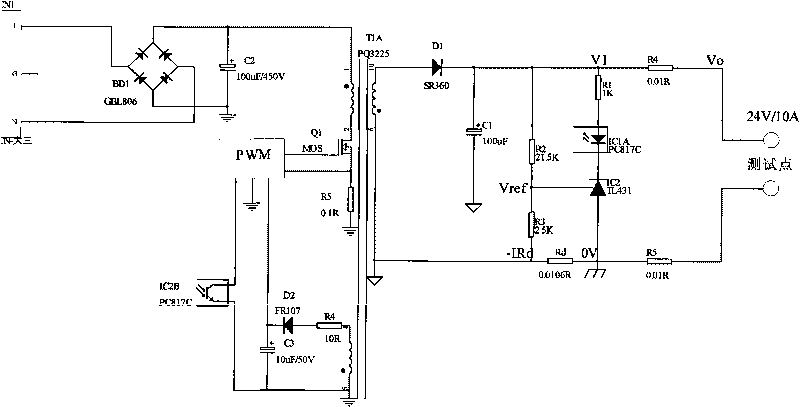

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

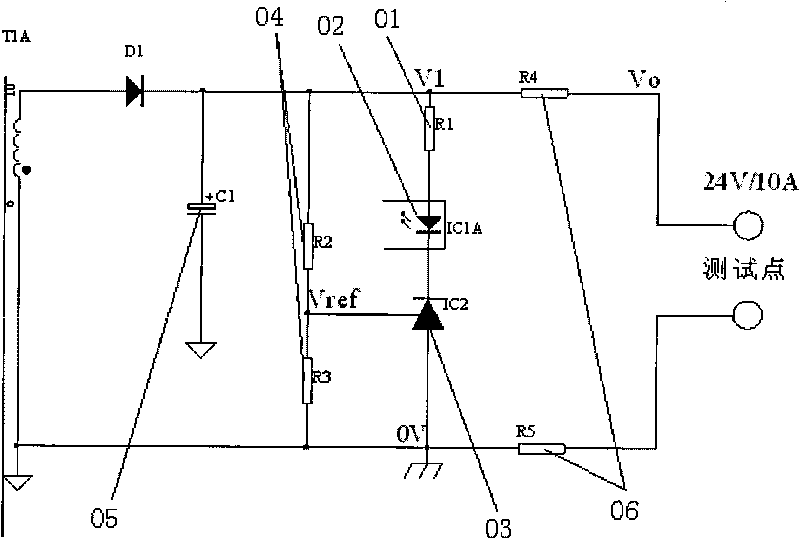

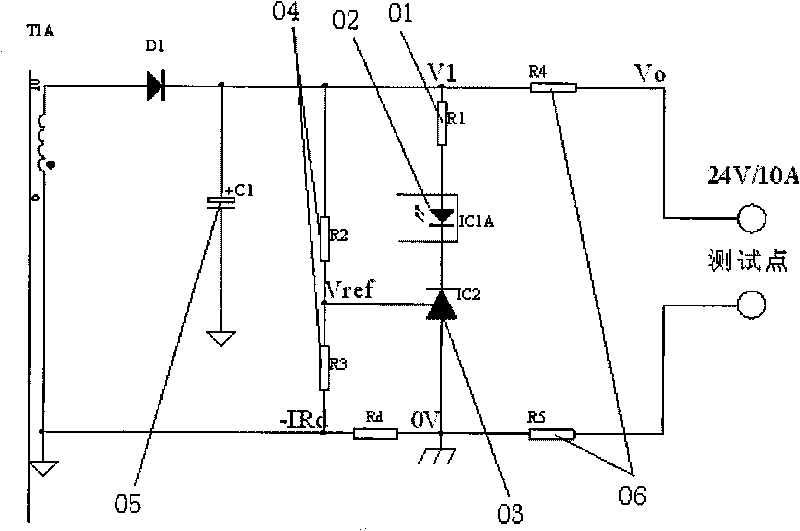

[0022] figure 1 Indicates the circuit diagram of the feedback part of the traditional switching power supply; sampling resistor 04: determines the output voltage; reference source 03: generates the reference voltage; photocoupler 02: transmits the secondary feedback signal to the primary side; wire resistance 06: feedback in the actual power supply The real impedance existing in a section of wire from the sampling point to the load end; current limiting resistor 01: limit the current in the optocoupler, and set the operating point of the feedback loop.

[0023] In the feedback design of the switching power supply, the traditional method is to connect the reference ground of the reference source 03 and the series sampling resistor 04R 2 , R 3 Circuit R 3 connected together so that the output voltage depends on the following equation:

[0024] V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com