Composite nozzle and method for producing composite fiber

A technology of composite nozzles and polymers, applied in fiber processing, textile and papermaking, spinneret assemblies, etc., can solve the problems of difficult structure, high equipment cost, complicated nozzle structure, etc., to prevent convergence and high dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

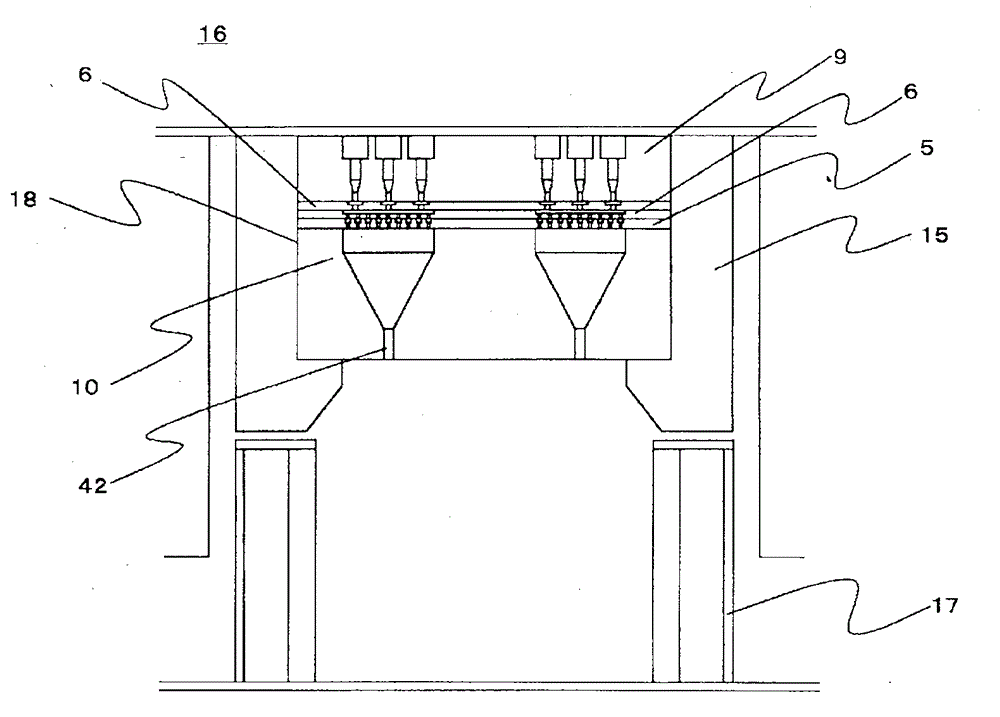

[0157] Polyethylene terephthalate (PET melt viscosity: 120 Pas) with an intrinsic viscosity (IV) of 0.63 dl / g as the island component, and 5-sulfonic acid metabolite with an IV of 0.58 dl / g as the sea component polymer Sodium phthalate 5.0 mol% copolymerized PET (melt viscosity of copolymerized PET: 140 Pas) was melted at 290°C, measured, and flowed into a Figure 6 The spin pack of the composite nozzle according to this embodiment shown discharges a sea-island composite polymer flow from the discharge hole of the nozzle. In addition, 700 island component discharge holes were perforated at equal intervals for one discharge introduction hole for the island component polymer in the distribution plate at the lowest layer. The sea-island ratio was set to 30 / 70, and oil was added to the discharged composite polymer flow after cooling and solidification, and it was wound at a spinning speed of 1500m / min, and 110dtex-15 filaments were selected (single-hole discharge capacity 2.25g / mi...

Embodiment 2

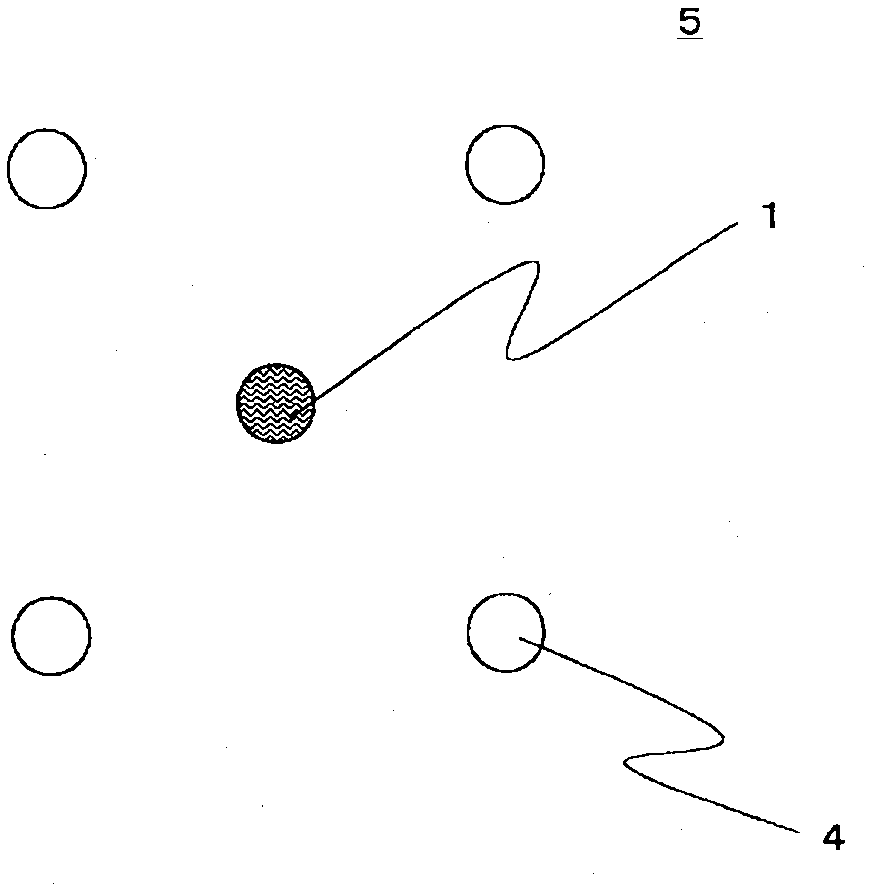

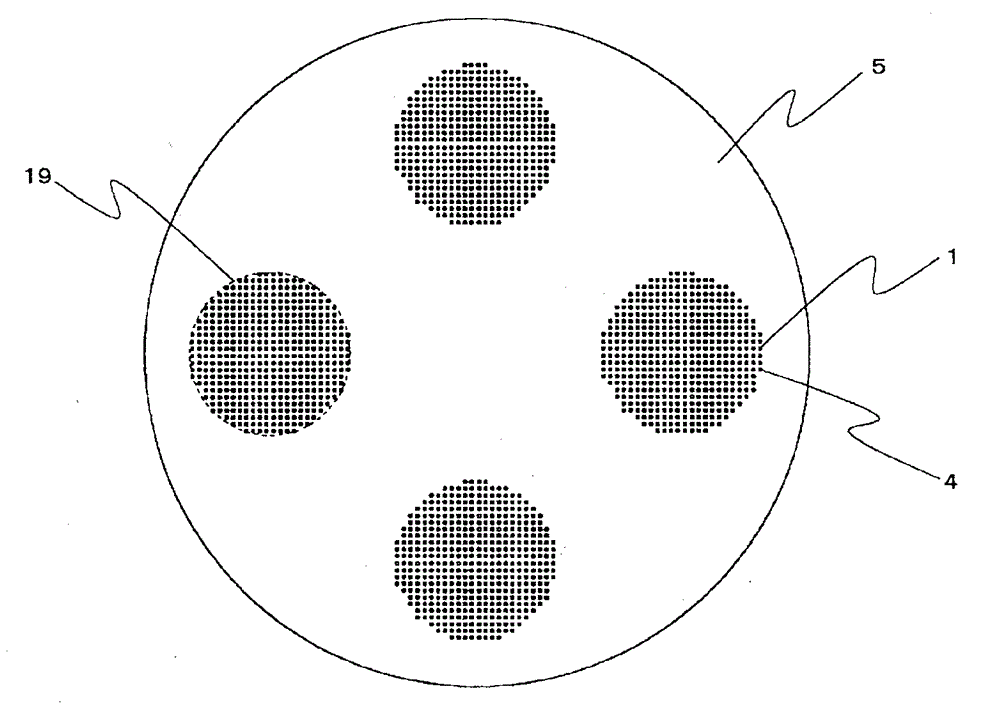

[0160] Such as figure 2 As shown, the arrangement of the island component discharge holes and the sea component discharge holes of the distribution plate on the lowermost layer is arranged in such a manner that n=4, which are the conditions of formulas (1), (2) and (3), are arranged. The same composite nozzle as in Example 1. In the distribution plate at the bottom layer, 600 island component discharge holes are perforated at equal intervals for one discharge introduction hole for the island component polymer. The sea-island ratio was set to 50 / 50, and other than that, spinning was performed with the same polymer as in Example 1, the same fineness, and spinning conditions, and 9000 multifilaments were selected. Here, in the composite nozzle used in Example 2, the island component discharge hole and the sea component discharge hole with a hole diameter of 0.2 mm have a radius R1 of 0.25 mm on the imaginary circular line C1, and a radius R2 of the imaginary circular line C2 of...

Embodiment 3

[0162] Such as image 3 As shown, the arrangement of the island component discharge holes and the sea component discharge holes of the distribution plate on the lowermost layer is arranged in such a manner that n=6, which are the conditions of formulas (1), (2) and (3), are arranged. The same composite nozzle as in Example 1. In the distribution plate of the lowest layer, 500 island component discharge holes are perforated at equal intervals for one discharge introduction hole for the island component polymer. The sea-island ratio was set to 50 / 50, and other than that, spinning was performed with the same polymer as in Example 1, the same fineness, and spinning conditions, and 7500 multifilaments were selected. Here, in the composite nozzle used in Example 3, the island component discharge hole and the sea component discharge hole with a hole diameter of 0.2 mm have a radius R1 of 0.33 mm on the imaginary circumferential line C1, and a radius R2 of the imaginary circumferenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com