Positive electrode active material

A positive active material and electrode technology, applied in the field of positive active materials, can solve the problems of high capacity and unstable crystal structure, achieve high capacity, improve initial charge and discharge efficiency, discharge capacity retention rate, and maintain capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

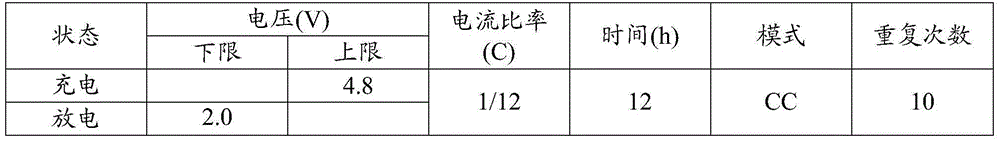

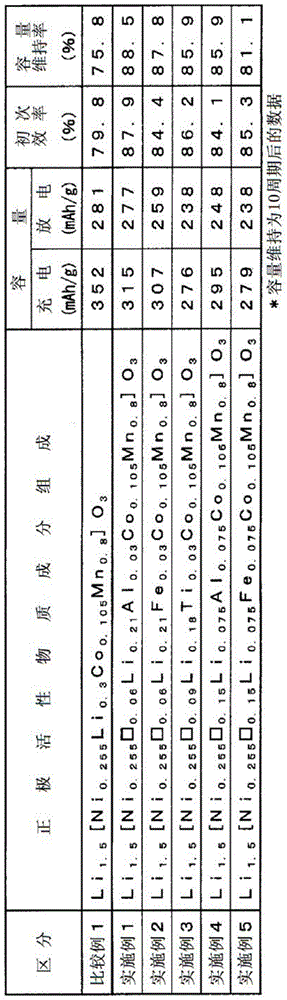

[0083] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0084] (1) Synthesis of positive active material

[0085] As the positive electrode active material, a composite carbonate method was used to synthesize a solid solution composed of a lithium-containing composite oxide.

[0086] First, as the starting material, use the sulfates of Ni, Co, Mn, Al, Fe, and Ti, and weigh them separately to make Ni, Co, Mn, Al, Fe, and Ti reach the specified molar ratio, Stir and mix in medium, and add 2M sodium carbonate dropwise to prepare the precursor of composite carbonate.

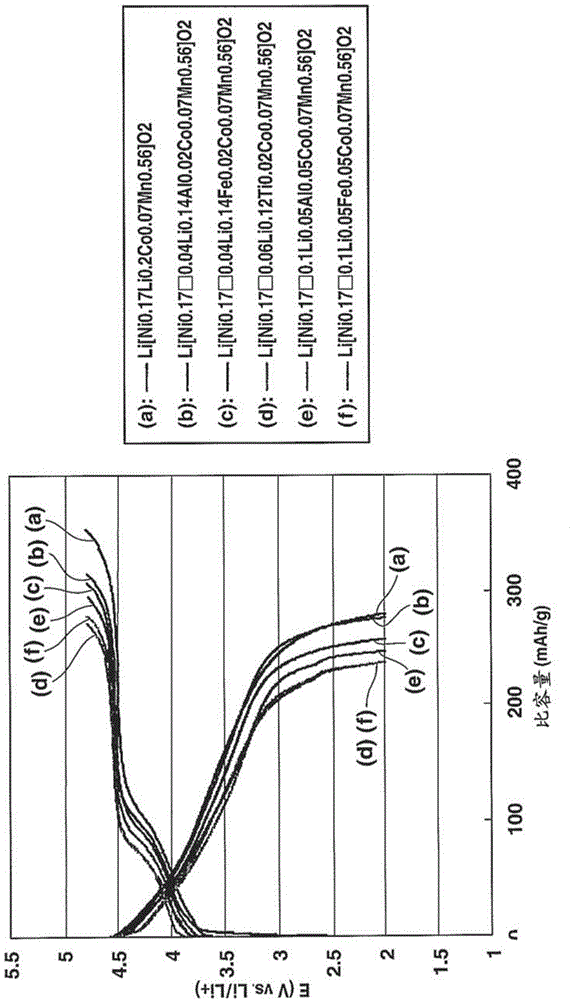

Embodiment 1

[0092] To form Li 1.14 Ni 0.17 Co 0.07 Al 0.02 Mn 0.56 O 2 , The molar ratios of Ni, Co, and Mn were set to 0.2125, 0.0875, and 0.7, respectively, and adjusted so that the molar ratio of Li relative to the metal composition M made up of Ni-Co-Mn was 1.425, and so that Al It is adjusted so that the metal composition M is 0.025, and mixed.

Embodiment 2

[0094] To form Li 1.14 Ni 0.17 Co 0.07 Fe 0.02 Mn 0.56 O 2 , The molar ratios of Ni, Co, and Mn are set to 0.2125, 0.0875, 0.7, respectively, and the molar ratio of Li is adjusted so that the metal composition M of the Ni-Co-Mn is 1.425, and the ratio is adjusted to make Fe It is adjusted and mixed so that the metal composition M is 0.025.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com