A V-method molding sand treatment system and method

A processing system and molding sand technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, manufacturing tools, etc., can solve the problems that the boiling cooler is difficult to boil fully, the cooler cannot work, and the sand cannot be cooled. , to achieve the effect of thorough removal of impurities, flexible and convenient production, and saving equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

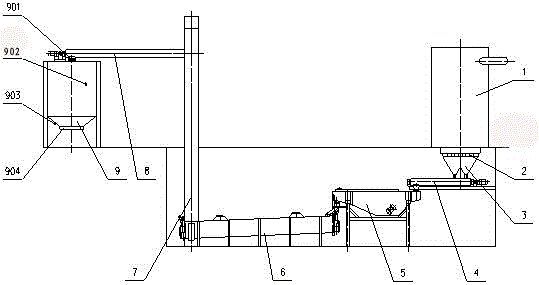

[0026] As shown in the figure, a V-method molding sand processing system includes a shakeout cover 1, a conveying mechanism A4, a screening device 5, a sand cooler 6, a bucket elevator 7, a conveying mechanism B8 and a sand storage Bucket 9, wherein the bottom of the shakeout cover 1 is connected with a chute 3, and a grid 2 for filtering sand is provided between the shakeout cover 1 and the chute 3;

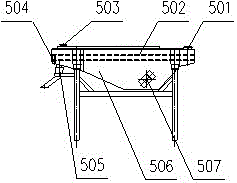

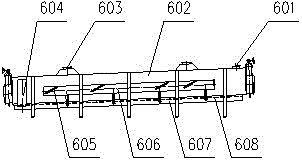

[0027] Described screening device 5 comprises screening device body 506, is arranged on the screen cloth 502 in screening device body 506, is used to drive the vibrating motor 507 that screening device 5 works and is arranged on the screening device body 506 The feed port I501, the discharge port I505 and the miscellaneous discharge port 504, wherein the mesh aperture of the screen 502 is 0.42~0.074mm, the discharge port I505 is set above the sand cooler 6 feed port II601, and the screening The upper part of the device body 506 is also provided with a ventilation and dust remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com