Cold drawing seamless pipe manufacturing technology for trailer gas cylinder

A manufacturing process and technology of seamless steel pipes, which are applied in the field of manufacturing process of cold-drawn seamless pipes for trailer gas cylinders, can solve the problems of low geometrical dimensional accuracy of steel pipes, no published patent documents have been found, and failure to meet user requirements, etc. Excellent performance, good surface quality, good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific examples, and the following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

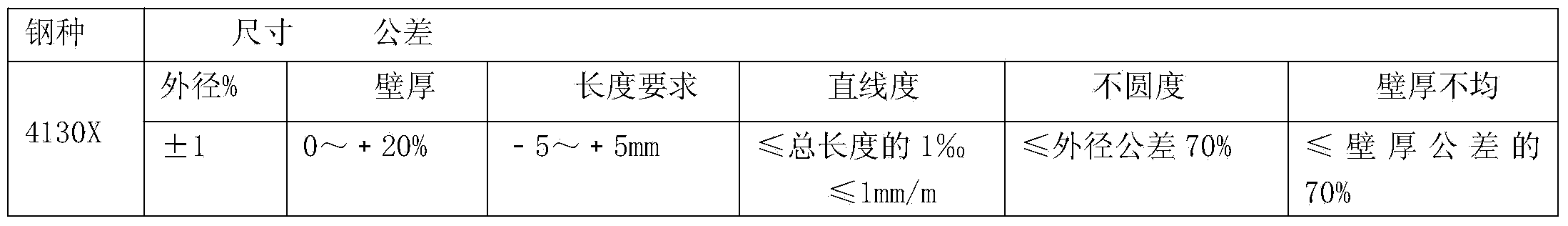

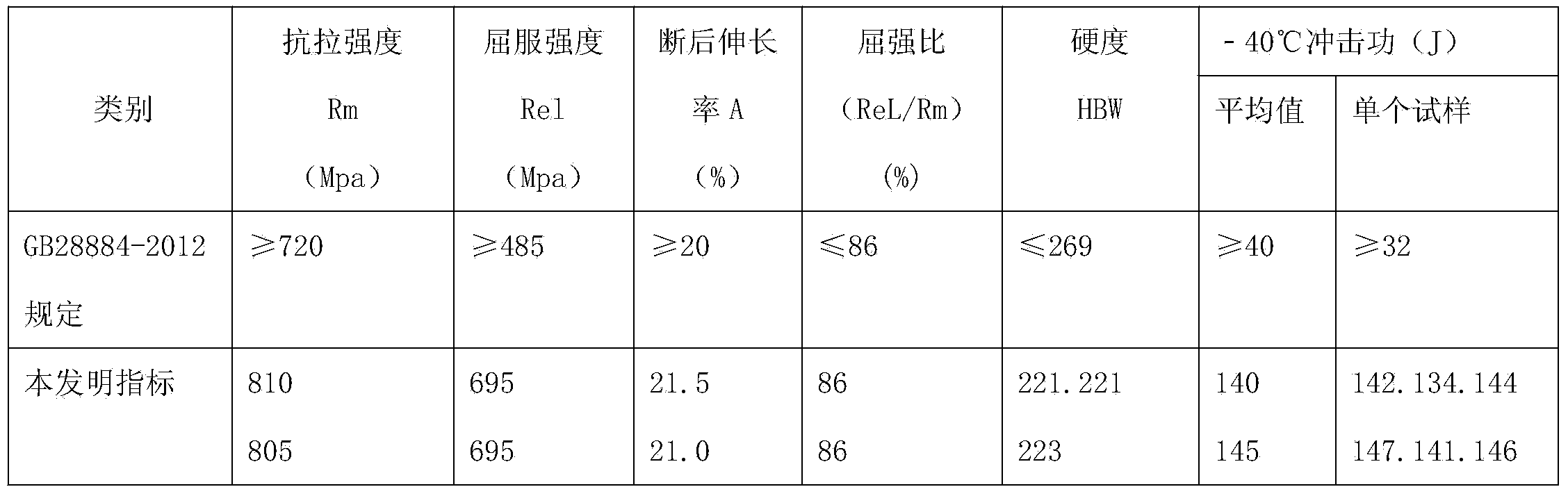

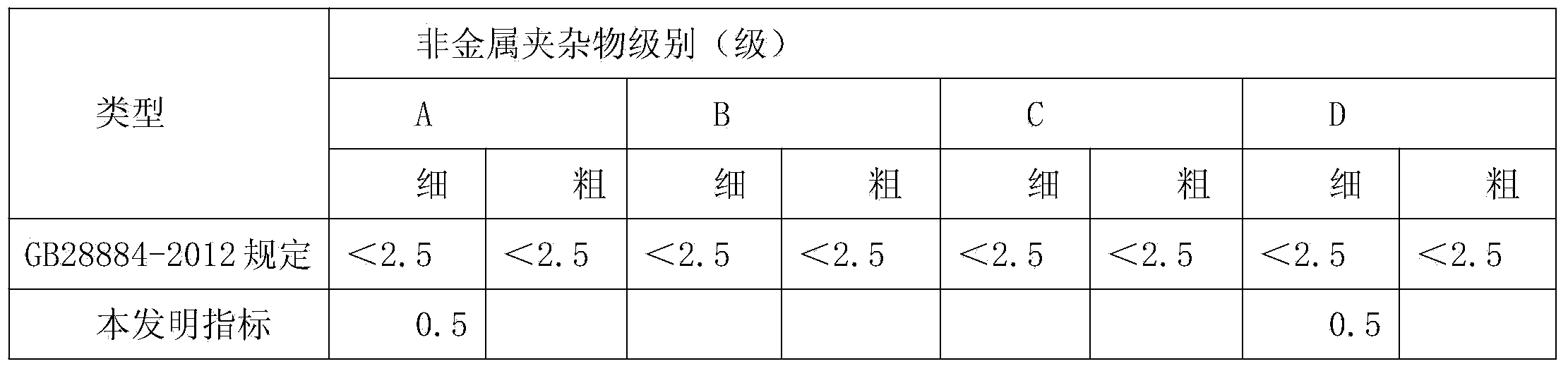

[0028] A manufacturing process of cold-drawn seamless steel pipes for trailer gas cylinders. The seamless steel pipes are made of 4130X, Φ508X25 hot-rolled raw material pipes, which are thermally expanded to Φ575X24.0 thermally expanded raw material pipes, and then pickled and lubricated. process, and finally cold-drawn to Φ559X23.4 cold-drawn finished tube, the specific process steps are:

[0029] 1. Thermal expansion process: thermal expansion of the hot-rolled raw material tube Φ508X25 to Φ575X24: the steps are:

[0030] ⑴Inspect the internal and external surface quality, outer diameter, wall thickness and wall thickness deviation of the same section of the hot-rolled raw material pipe of the specification Φ508X25. If there are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com