Sliding fixing device for slate chamfering processing machine

A fixing device and processing machine technology, applied in the direction of grinding machine parts, stone processing equipment, working accessories, etc., can solve the problems of large volume and high cost, improve production efficiency, fast fixing speed, improve processing quality and work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

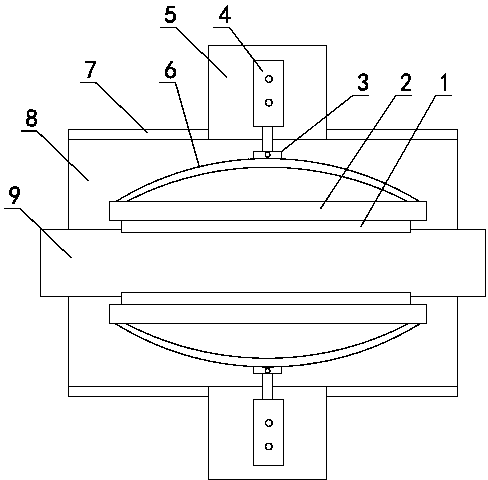

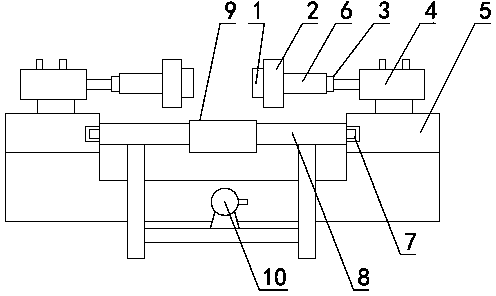

[0025] Such as figure 1 , figure 2 , image 3 As shown, the sliding and fixing device used on the slate chamfering processing machine includes a workbench 8, a conveyor 9, a slide rail 7 and a slider 5. The workbench 8 is a four-legged rectangular structure, and the left and right The conveyer 9 is provided with two parallel slide rails 7 on the workbench 8, the sliding direction of the slide rails 7 is consistent with the conveying direction of the conveyor 9, and a slide block 5 is installed on each slide rail 7, The two sliders 5 are connected as a whole through the sliding frame of the groove type structure, the sliding frame is located at the lower part of the table 8, and the corresponding sliding frame is installed on the working table 8 for the sliding block power mechanism for the sliding block 5 to slide along the slide rail 7, On each slider 5, a slate-fixed hydraulic cylinder 4 is installed, and two slate-fixed hydraulic cylinders 4 are arranged axially symmetri...

Embodiment 2

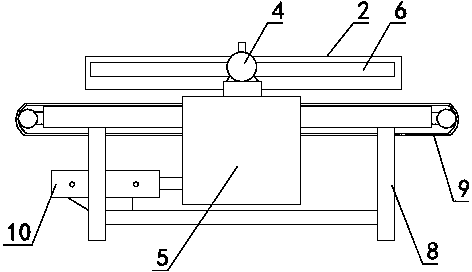

[0030] This embodiment is changed on the basis of Embodiment 1, such as Figure 4 As shown, the conveyor 9 is changed into a roller structure; the slider power mechanism becomes two sliders to move the pneumatic cylinder 11, as Figure 4 Shown, be installed on the left and right sides of workbench 8 bottoms respectively. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com