A device and treatment method for zero discharge of desulfurization wastewater

A desulfurization wastewater, zero-discharge technology, applied in gaseous discharge wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of cyclone blockage and unsatisfactory liquid-solid separation effect. , to save space, reduce investment and equipment failure rate, and improve dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

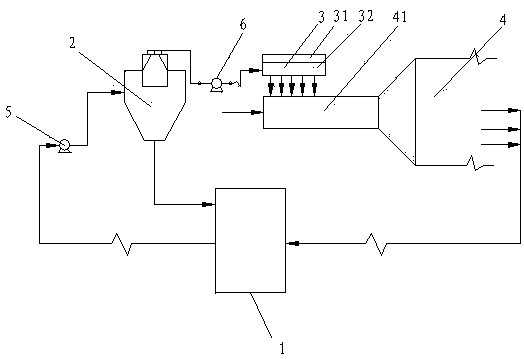

[0024] See Figure 1 to Figure 2 The device for zero discharge of desulfurization wastewater in this embodiment is composed of a desulfurization system 1, a two-stage wastewater cyclone 2, an ultrasonic atomization nozzle 3, a dust collector 4, a wastewater pump 5, and a wastewater transfer pump 6.

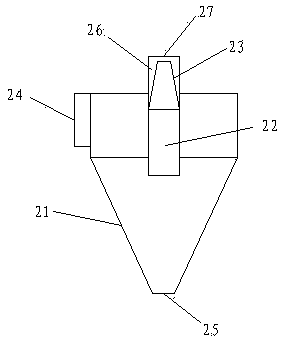

[0025] The two-stage waste water cyclone 2 in this embodiment includes a cyclone body 21, an overflow tube 22, and a filter screen 23. The cyclone body 21 has the function of grading and removing fine particles, and the overflow tube 22 has overflow filtration. Function, the swirler body 21 is provided with a swirler inlet 24 and an underflow port 25, the underflow port 25 is located at the bottom of the swirler body 21, the overflow pipe 22 is arranged on the swirler body 21, and the overflow pipe 22 A filtrate chamber 26 is provided. The filter screen 23 is installed in the filtrate chamber 26. The overflow pipe has an overflow port 27. The overflow port 27 of the overflow pipe 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com