A method for preparing magnolol and honokiol from magnolol leaves

A technology of honokiol and magnolol, applied in the direction of chemical instruments and methods, preparation of organic compounds, non-central analgesics, etc., can solve the problems that are not conducive to the implementation of industrialization, not conducive to the protection of laborers, and increase operational risks In order to achieve the effects of low cost, large sample loading and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

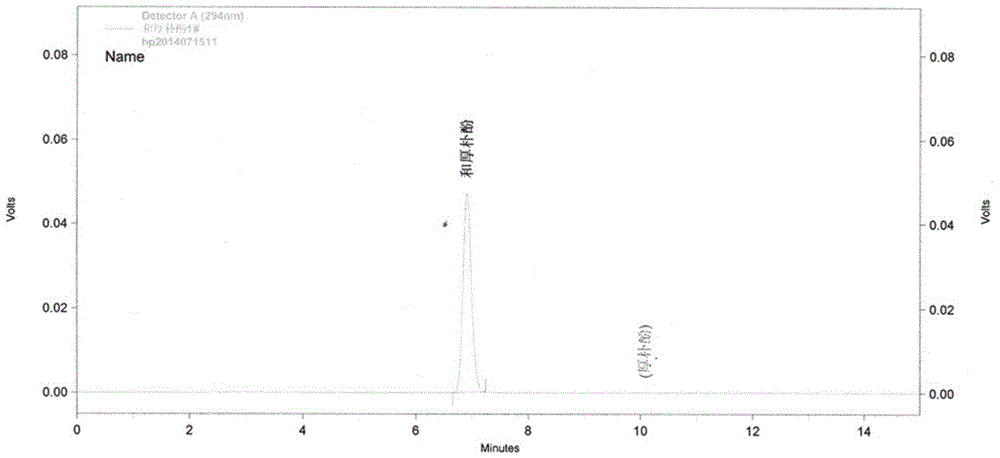

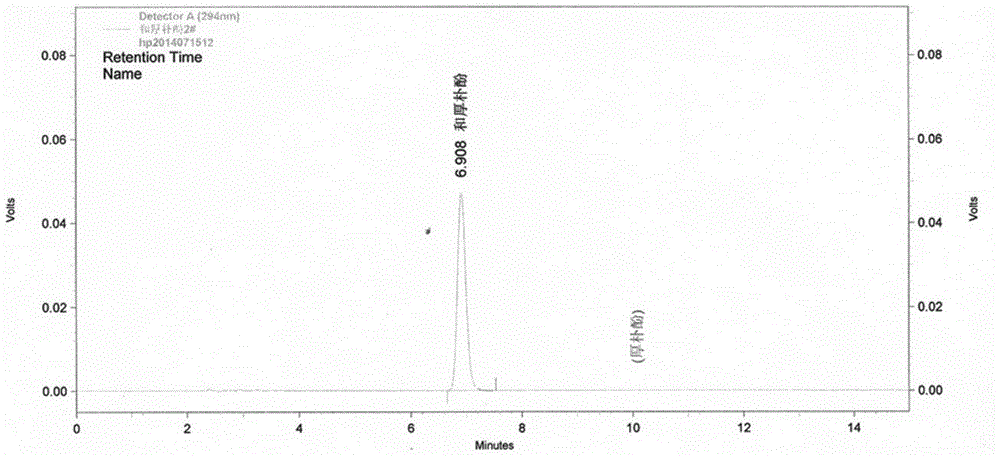

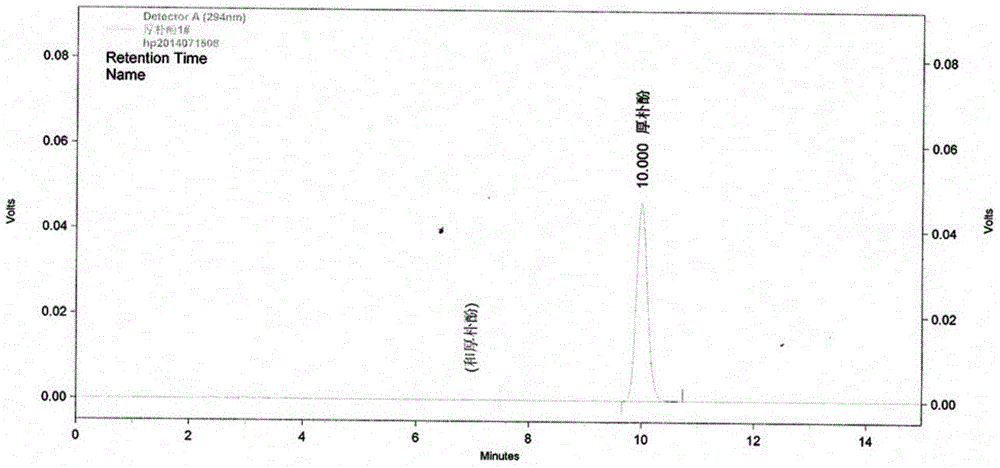

Image

Examples

Embodiment 1

[0038] 1. Take 96g of Magnolia officinalis leaves and grind them to a particle size of 40 mesh;

[0039]2. Magnolia officinalis leaf powder is reflux extracted three times with ammonia water to adjust the pH value of 10 95% ethanol solution, the extraction temperature is 60 ° C, wherein the first 500ml solution is reflux extracted for 2 hours and then filtered, and the filter residue is reflux extracted for the second time with 500ml solution for 1 hour After filtering, the filter residue was refluxed for the third time with 500ml of solution and filtered for 0.5 hours, and the three extracts were combined; the pH value was adjusted to 6 with hydrochloric acid, and the solvent was recovered to obtain a crude extract (28.8g);

[0040] 3. Dissolve the crude extract in 300ml of water, extract 3 times with dichloromethane, 300ml each time, combine the dichloromethane solution, and evaporate to dryness to obtain extract (14.2g);

[0041] 4. Take 500g of small-pore separation resin ...

Embodiment 2

[0045] 1. Take 95g of Magnolia officinalis leaves and crush until the particle size is 40 mesh;

[0046] 2. Magnolia officinalis leaf powder is reflux extracted three times with ammonia water to adjust the pH value of 95% ethanol solution, the extraction temperature is 60 ° C, wherein the first 500ml solution is reflux extracted for 2 hours and then filtered, and the filter residue is reflux extracted for the second time with 500ml solution for 1 hour After filtering, the filter residue was refluxed for the third time with 500ml solution and filtered for 0.5 hours, and the three extracts were combined; the pH value was adjusted to 6 with hydrochloric acid, and the solvent was recovered to obtain a crude extract (28.2g);

[0047] 3. Dissolve the crude extract in 300ml of water, filter, dissolve the residue in 100ml of acetone, add 400ml of water to form a suspension, use 100g of alumina to absorb and enrich, collect the effluent, evaporate to dryness, and obtain an extract (13.3...

Embodiment 3

[0052] 1. Take 98g Magnolia officinalis leaves and grind them to a particle size of 40 mesh;

[0053] 2. Magnolia officinalis leaf powder is reflux extracted twice with ammonia water to adjust the pH value of 9 60% methanol solution, the extraction temperature is 70 ° C, wherein the first 500ml solution is reflux extracted for 3 hours and then filtered, and the filter residue is reflux extracted for the second time with 500ml solution 2 Filtrate after 1 hour, combine two extracts; Regulate pH value 7 with hydrochloric acid, reclaim solvent, obtain crude extract (29.4g);

[0054] 3. Dissolve the crude extract in 300ml of water, extract twice with dichloromethane, 300ml each time, combine the dichloromethane solution, evaporate to dryness, and obtain extract (15.2g);

[0055] 4. Take 500g of small pore size separation resin Chroma-R204 and pressurize the column, equilibrate the column with methanol aqueous solution with a concentration of 35% by volume, and then slowly add the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com